|

|

|

|

|

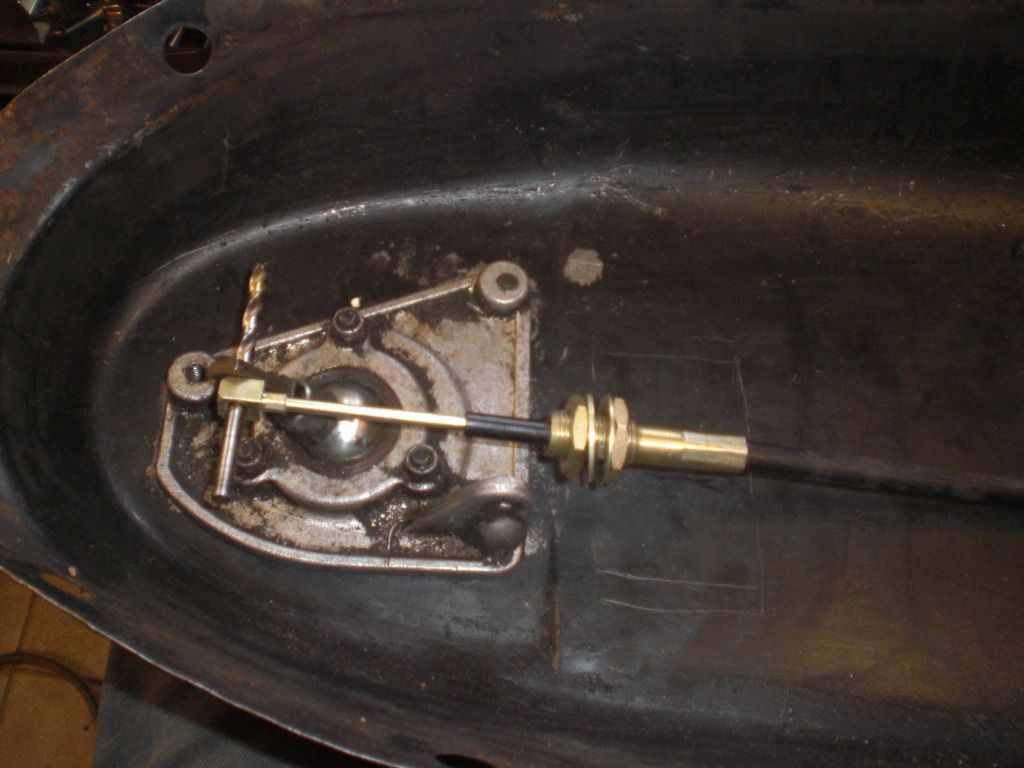

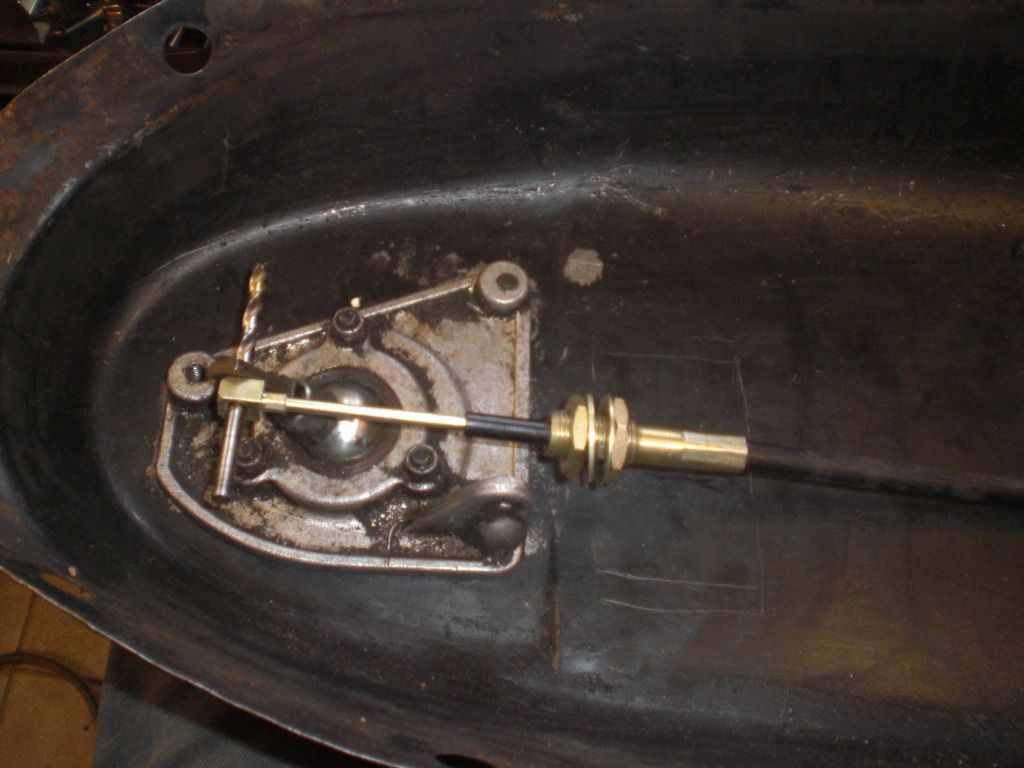

Thanks! Had kept all the metal pieces which were cut out of the shell and made a picture of it  Haven't started assembling the body yet and in the limited amount of garage time, i am preparing parts for powder coating. Lots of parts already have been done but forgot a few and some parts were robbed to use into my daily P5B. I already knew that the battery box in my daily P5B was poor as most are.  Had a spare one which i used in the boot of my daily P5b for spare parts and tool storage. To store the tools and parts, i made a tray out of stainless sheet material to install above the LPG tank  and covered it with vinyl  Now have a neat storage for the tools and spare parts  The spare battery cover needed a new bottom  The old bottom was cut out and a new one was made. for folding the edge of the large hole in the middle, i made a wooden jig to fold the edge  Welded the new bottom with plug welds   Also made 1 new side bracket and a battery retaining bracket as these were missing  Then onto the transmission tunnel cover. This car will get a 4 ZFHP22 box to replace the BW35. The shifter to box connection is original done with rods but for the 4ZF a cable from a Jaguar XJ40 will be used. This cable has a adjustment near the shifter and to have easily access to this, i wanted an extra hole in the cover. First fitted the shifter with cable to the cover to determine the position of the hole  Then cutted out the material, folded the edges with hammer and dolly and made a cover plate out of 1,5mm sheet metal  and welded some nuts to the underside  The upper dashboard piece was forgotten in previous powder coat badges and as it was rather rusty, i removed the hardened and damaged vinyl and foam to get the frame powder coated   |

| |

|

|

|

|

|

|

|

|

|

|

There is at least 25 bucks of scrap metal on that blanket. Enough for a kratje Hertog Jan

|

| |

|

|

|

|

|

Feb 15, 2017 19:45:46 GMT

|

There is at least 25 bucks of scrap metal on that blanket. Enough for a kratje Hertog Jan You seem to know more dutch beer brands other then Heineken! Some progress to show First brought some parts to the powder coater  Then coated all hollow area's of the shell with Noxudol  Hooked the shell to the rotater and started coating the hollow area's   to have good access to the rear valance, sills ect, i turned the shell upside down     Removed the wax which was on the body an wait untill the drips stop. Then will clean the shell with white spirit to remove the remains of the wax. Also another Volvo steeringbox arrived. This one only costed 100 Euro and feels solid. I drained the oil which looked clean (on the picture it looks very dirty which is caused by spraying the housing with brake cleaner to remove dirt) and will remove the rust, give it a coat of primer and black paint and will replace the 2 seals as a precaution.  Peter |

| |

|

|

bmgm3

Part of things

Posts: 19

|

|

Feb 17, 2017 22:44:59 GMT

|

|

Had to join the forum to be able to say great work. Please keep the details and pics coming, been looking for a great nut and bolt rebuild thread on a P5B and love this.

|

| |

|

|

|

|

|

Feb 19, 2017 21:34:51 GMT

|

Had to join the forum to be able to say great work. Please keep the details and pics coming, been looking for a great nut and bolt rebuild thread on a P5B and love this. Lots of stuff to come soon i hope. This weekend, i fitted the overhauled sub frame which was sitting on a trolley in my workshop for quit some time.  Removed the tempory frame which connected the shell to the rotator  Then with the engine crate lifted the sub frame and re connected it to the trolley with some extension bars  And put the rear on another trolley  Rolled the sub frame under the car  And by lowering the adjustable axle stands, the 6 bolts to connect the subframe to the car could be fitted  It took approx 2 hours and no scratches on subframe or shell  some pictures of the repair of the sub frame It had several dents  The dented area's were cut out with a grinder, straightened and then welded in  the inside was rust free and looking very good       I brought it then to the powdercoater, As i didn't have a towbar on my car, i put it on my roof carrier with the engine crane and connected it with some special brackets On the pictures benath, the frame was powder coated and collected   all suspension parts were shotblasted and painted or powder coated    rubber bushes renewed  Bullet proof baljoints opened, cleaned, new grease and new rubber fitted    And all the parts were fitted to the powder coated subframe with re galvanised bolts and nuts  most mechanical parts are really bullet proof on the Rover P5B so these can be rebuild easily. Last week i got a call from my brother in law, who had checked the oil level on his 5 year old Peugeot and it seems that the lower dipstick is made of plastic and broke, leaving the lower part in the engine. I really hate working on modern cars with these plastic clips/parts which are easily broken after a few years. Thats it for now Peter |

| |

|

|

|

|

|

Feb 19, 2017 21:51:54 GMT

|

|

Fabulous work. Just stunning.

|

| |

|

|

|

|

|

Feb 19, 2017 22:02:54 GMT

|

|

Beautiful

|

| |

|

|

|

|

|

Feb 22, 2017 12:47:22 GMT

|

|

Hi Peter, nice work you are doing there, you probably have loads of P5B parts but I have a load that I need to get rid of for a small donation if you are interested, cant be bothered putting on Ebay rather it all go to good home

Thanks

Dave

|

| |

|

|

dbdb

Part of things

Posts: 821

|

|

Feb 22, 2017 13:35:44 GMT

|

|

What a wonderful thread - a superb job on a beautiful car. It is very impressive.

|

| |

|

|

|

|

|

Feb 22, 2017 17:33:25 GMT

|

|

that subframe is a beast ! in close up it could be a landrover chassis !

|

| |

|

|

|

|

|

|

|

|

|

|

Peter,

Stunning work..., with such clever solutions to the challenges you've encountered. Love those adjustable axle stands, who makes them?

Enjoying this...

Lance

|

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,353

Club RR Member Number: 64

|

Rover P5B Coupe - MGB V8glenanderson

@glenanderson

Club Retro Rides Member 64

|

Feb 23, 2017 10:03:25 GMT

|

that subframe is a beast ! in close up it could be a landrover chassis ! You can see they were designed by the same hand. 😃 |

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

Feb 26, 2017 21:38:07 GMT

|

Fabulous work. Just stunning. Thanks George. I read about the problems you had with the brake hoses. Brake hoses on my car haven't been fitted as i also had troubles. The thread of the Goodridge hoses was way too short which could cause a very dangerous situation. Didn't get a convincing answer from Goodridge yet. |

| |

|

|

|

|

|

Feb 26, 2017 21:39:15 GMT

|

Thanks Jim. I see you already started fitting parts to your shiney shell |

| |

|

|

|

|

|

Feb 26, 2017 21:42:06 GMT

|

Hi Peter, nice work you are doing there, you probably have loads of P5B parts but I have a load that I need to get rid of for a small donation if you are interested, cant be bothered putting on Ebay rather it all go to good home Thanks Dave Thanks Dave. I have parts from 2,5 cars and not needing much anymore. Need a set of headrest lights but these are very scarce and need to figure out what to do with the interior Peter |

| |

|

|

|

|

|

Feb 26, 2017 21:42:36 GMT

|

What a wonderful thread - a superb job on a beautiful car. It is very impressive. Thanks! |

| |

|

|

|

|

|

Feb 26, 2017 21:43:27 GMT

|

that subframe is a beast ! in close up it could be a landrover chassis ! It surely is a beast and very well made! |

| |

|

|

|

|

|

Feb 26, 2017 21:45:45 GMT

|

Peter, Stunning work..., with such clever solutions to the challenges you've encountered. Love those adjustable axle stands, who makes them? Enjoying this... Lance Thanks Lance. The axle stands are chinese ones but the quality is oke and are very handy. I bought these from a kind of Dutch ebay but cannot find those anymore. The price was Euro 50,- a piece which is reasonable. |

| |

|

|

|

|

|

Feb 26, 2017 21:53:55 GMT

|

Brake hoses on my car haven't been fitted as i also had troubles. The thread of the Goodridge hoses was way too short which could cause a very dangerous situation. Didn't get a convincing answer from Goodridge yet. Seems that unless you go public, via social media, you won't get a satisfactory response. Sad but certainly true in my case. |

| |

|

|

|

|

|

Feb 26, 2017 21:53:59 GMT

|

Some progress to show Made some brackets to connect the shell to the rotator The front ones  the rear ones  To avoid that the chassis legs are damaged, i fitted the rear bumper brackets which are powder coated  The car and the floor are still rather "greasy" as the wax is not fully "hardened" I have 5 boxes with refurbished parts which are waiting to be fitted  Fitted some brake parts to the engine compartment. Its amazing how many parts are used in the parking brake mechanism. all those bolts, springs, bushes ect and most of it is bullet proof. The number of new parts i needed is relatively low compared to the poor bodywork. So mechanically the P5B is a nice car to restore as it is very well designed   Fitted most of the new Automec brake pipes and the pipe which runs from the master brake cilinder to the booster is wrong. It is an pipe for RHD . Although i bought the set years ago, Automec is willing to supply the right pipe without hesitation. That is good Customer service. Also fitted the brake pedal and the master brake cilinder which is new. I gave that a coat of epoxy preimer as paint as these rust. I will be using silicon brake fluid which is not agressive to paint. The rest of the parts are powder coated or zinc plated. Also the pedal rubber is new.  This is a really enjoyable stage in the restoration proces! Peter |

| |

|

|

|

|