|

|

|

Sept 14, 2016 14:12:35 GMT

|

EDIT: this is no longer going to be a soapbox. Page 2 see's me find something else for that and turn this in to a Toylander-esque, err.. thing.OK, so first off I've posted this on this forum because the end result couldn't be more retro. I intend to shell this thing to look like a Hansom Cab:  The reason? Well it was developed while the inventor lived in my town (Hinckley) and I am a member of a local historical group. So I would say this is the perfect forum for this little build. So anyway, £20 eBay buy and a trip to Enfield (not that bad, was in Watford at my brothers anyway) and I now have this taking up residence in my garage:  Job list is pretty simple to start with: 1) remove motor to allow freewheeling and design and a fit brake system 2) sort steering (possible ratio change to reduce output - slightly worried it may be rather twitchy at speed currently) 3) fit safety devices of some kind 4) design, build and fit relevant body 5) paint it 6) find a toy horse the right size I've got a Facebook page running for the history group to keep up to date also if you are interested. So, job 1 is to remove the motor and get the thing freewheeling and fit some brakes. Dropped the axle off and removed the motor:   Easy, but I now know it has a transaxle which will impede speeding too much  . BUT the weight of it, it's yet to be constructed body, and me will still freewheel fairly nicely I think  . I need to work on the braking system before I can test that. Which leads me to a brilliant surprise - while cleaning general detritus I noticed some springs near the front wheels. Quick inspection shows some form of hub brake already fitted to both wheels:  Just need replacement cables and some BMX levers then I can run it down some inclines.

|

| |

Last Edit: Oct 12, 2016 13:09:41 GMT by mikeyp247

|

|

|

|

|

|

|

Sept 15, 2016 3:12:51 GMT

|

|

As a mobility scooter user I can say that they get very unstable at speed as only designed for max of 8mph. Problem is kingpin inclination is neutral to make them easy to steer so you'd need to cut and reweld front of frame to provide better geometry. It's this and not steering gearing that makes them twitchy.

|

| |

|

|

|

|

|

Sept 16, 2016 12:25:40 GMT

|

Cheers for that composimmonite - steering is on the list.  Further thought given and list of problems raised: NARROW FRONT TRACK Yep, the track is narrow. It looks like a bit of cut and weld to widen it is the only option that will work. I was hoping that by lowering the centre of gravity (or at least the bulk of the weight of it) would aid in speed (like a bullet!) The run is down a straight street with one jump (squeeky bum) and the only direction change is after the finish line (so should be braking at this point). More thought required. BRAKES These tiny hub brakes will overheat in about a second at anything like the speed we'll be doing...which means a stopping issue at the end of the run! But they are an easy option to use while setting up the seat height and steering. The plan then is to loose the rear geared transaxle and replace with a single bar axle and disc brake setup - although negative camber may also need to play a part and this would be difficult to achieve... That said, a cable operated push bike disc and the small size of wheels would give HUGE braking - skiiiiiid. So might be worth keeping the fronts on to feather and slow and use the rear to actually stop…? Or raise the axle and replace the wheels with larger (16"-20" BMX?) wheels... I am telling myself that the aim of this run isn’t about speed, it’s about learning how to do stuff, looking good and promoting HDPP – so slower is better.  STEERING Still a bit up in the air this one as need to address the track, but possibly a longer steering arm (and the tie rod(s) joining it) to scribe a larger radius, travelling further and meaning slower steering input (less twitchy). I have another possible solution using a hand-drill to inject some steering gearing that I am investigating - but may not be required if the track is widened. Also there is currently too much steering lock - but I have a plan for this one involving a lump hammer and the 2 'restricting' bars underneath the assembly (currently stop the stub-axles from fully locking). Might be academic if I increase the track width... It looks like front tie rod can be adjusted to achieve some 'toe in' - need to test how much As mentioned, negative camber is going to be difficult as there is no adjustment at the moment So now I am wondering in what order to progress. I think sort the track width first? Thinking of increasing width by 20%-25% each side to give a 50% overall width increase should do it - would make it almost square... |

| |

Last Edit: Sept 19, 2016 8:22:58 GMT by mikeyp247

|

|

|

|

|

Sept 16, 2016 14:25:07 GMT

|

|

Hi, I think you may need to rethink your braking, when you brake the weight transfers to the front where you have to have most breaking effort, If you have lots of braking at the rear it will lock up as you say and probably swap ends. Having a solid back axle won't help the steering, unless you want understeer.

Colin

|

| |

|

|

steveg

Posted a lot

Posts: 1,586

|

|

Sept 16, 2016 15:16:04 GMT

|

|

More scooter daftness, good stuff. I've built a go kart version for my son but need to get some parts for the motor and work out how the speed controller works. It's currently powered by a mains electric drill !

I think your plan is a better idea as it will be cheaper.

|

| |

|

|

|

|

|

Sept 18, 2016 20:22:54 GMT

|

Hi, I think you may need to rethink your braking, when you brake the weight transfers to the front where you have to have most breaking effort, If you have lots of braking at the rear it will lock up as you say and probably swap ends. Having a solid back axle won't help the steering, unless you want understeer. Colin Cheers Colin. Yep, braking is under consideration for front discs now as having walked the run again today it's much steeper than I realised (amaxing how it was nothing when I was younger!). Rear axle still under review. More scooter daftness, good stuff. I've built a go kart version for my son but need to get some parts for the motor and work out how the speed controller works. It's currently powered by a mains electric drill ! I think your plan is a better idea as it will be cheaper. Cheers Steve. Love to see your build if you have a link? |

| |

|

|

steveg

Posted a lot

Posts: 1,586

|

|

Sept 18, 2016 20:49:53 GMT

|

|

|

| |

|

|

|

|

|

Sept 18, 2016 21:23:41 GMT

|

Looks good, will be keeping my eye on that.  |

| |

|

|

|

|

|

Sept 19, 2016 14:52:14 GMT

|

Hand drill steering gearing looking like not a good option apparently: www.toylanderownersclub.com/forum/index.php?topic=942.0So steering may be direct with a cut/weld and rake adjustment. While I'm contemplating that, I'm going to strip out the hub brakes on one side tonight and see what space I have for adding disc brakes. |

| |

|

|

|

|

|

Sept 20, 2016 10:13:41 GMT

|

|

I'd consider using the front hubs & brakes on the rear and then adapting mini moto cable operated discs for the front.

|

| |

|

|

|

|

|

|

|

Sept 20, 2016 11:40:38 GMT

|

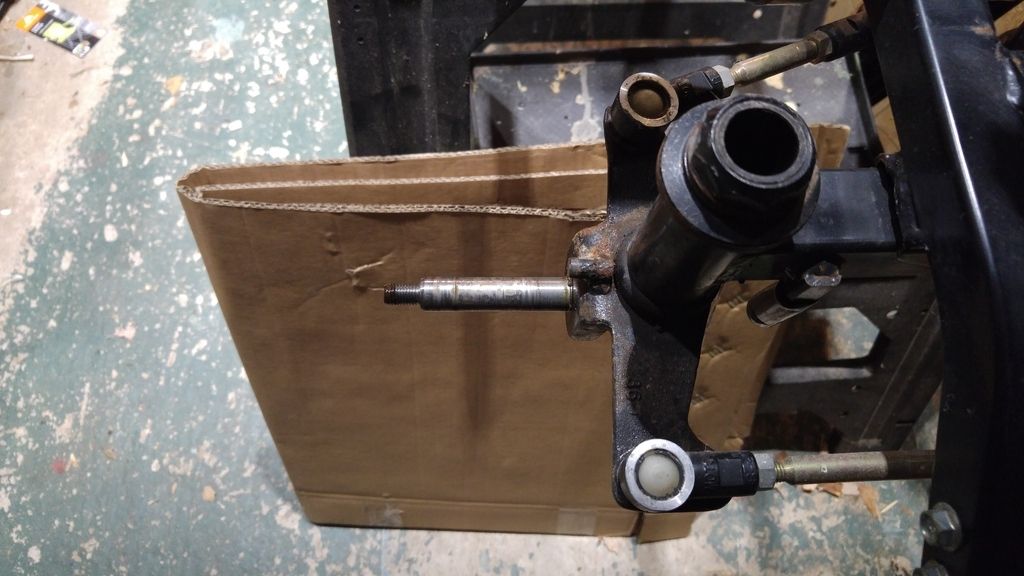

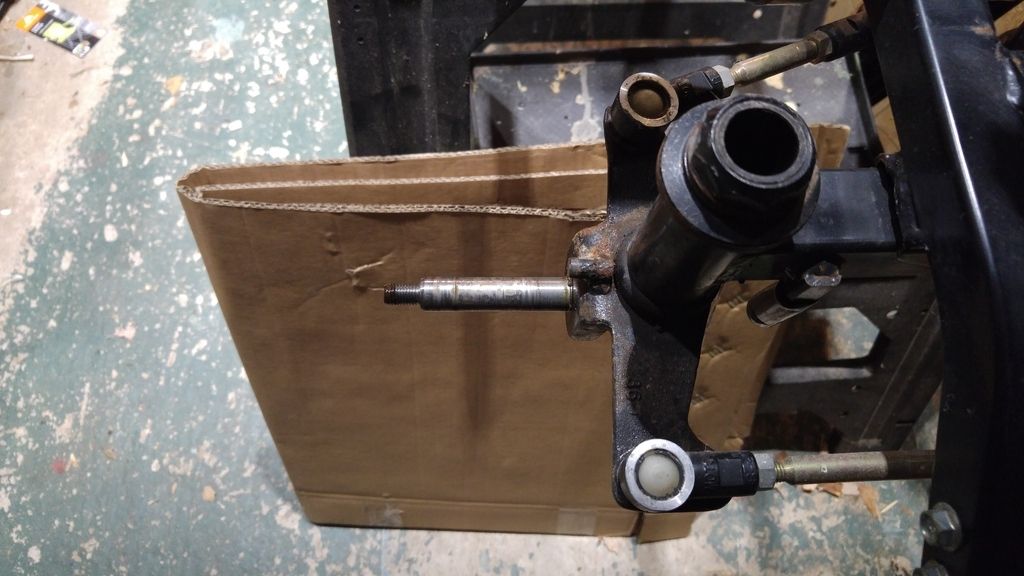

I'd consider using the front hubs & brakes on the rear and then adapting mini moto cable operated discs for the front. Mini-moto! You sir, are a genius.  Research commenced. So dropped one of the front wheels and hub brakes off last night:  Bit weeny. The stub axle looks like this:  Note the alignment lug for the hub - will need to replicate this if these end up on the back (so may just go balls out and put discs all round). STEERING So here's the current setup (minus wheel for viewing purposes):  I've done some quick photo editing to see how things might line up. Removal of the steering rack and axles (and shortening of front crossmember):  So my thought is to invert the steering as follows (forgive the crude 'shop):  So larger tie rod would be underneath the cart and steering inverted with directional tie rod on the top. Thoughts on this arrangement? |

| |

Last Edit: Sept 20, 2016 11:42:50 GMT by mikeyp247

|

|

|

|

|

Sept 20, 2016 11:46:27 GMT

|

|

Having looked at that last image now it has posted, I can see that to get the steering angle I was looking for, the tie rod and axles will graze the floor and snap (with current/small wheel on) and the steering will fowl on the chassis rail.

B*gger.

|

| |

|

|

|

|

|

Sept 20, 2016 11:52:28 GMT

|

Angle the steering rack:   |

| |

Last Edit: Sept 20, 2016 12:24:24 GMT by mikeyp247

|

|

|

|

|

Sept 20, 2016 21:11:24 GMT

|

|

Typical castor is 3 to 5 degrees on cars, so i wouldn't go to the effort of flipping it as I don't think you need as much castor as the flipped steering unit would let you have. I'd have thought 5degrees-10 degrees would be fine with the axle in the existing position and I'd of thought your steering link bar would still have plenty of ground clearance. Could you just warm the box section up with a blow torch and use a big shifter to bend it to the correct angle? Then when your happy they are both twisted the same angle, weld a bit of gusset in to keep it in position and support it?

|

| |

|

|

|

|

|

Sept 20, 2016 23:39:15 GMT

|

|

Could you rig a regenerative braking system, spin up a heavy flywheel via a clutch to loose speed then once you are round the corner transfer the momentum back to the kart?

|

| |

|

|

|

|

|

Sept 21, 2016 7:49:35 GMT

|

Could you rig a regenerative braking system, spin up a heavy flywheel via a clutch to loose speed then once you are round the corner transfer the momentum back to the kart? Cheers for the comment Dodge, although I wonder if that might be going a bit too far. I understand these are good to regain momentum after slowing for a corner - not an issue for me as the only corner is a slight curve towards to end and the bit after the finish line. Here's the course from last year: Start:  Midway point (jump & chicane to avoid jump):   And the lower section. You can see the only curve to negotiate at speed is minimal and the stopping area banks slightly uphill to the left:  What do you think? Regenerative braking a bit of an overkill maybe? |

| |

|

|

|

|

|

Sept 21, 2016 7:51:04 GMT

|

|

Ooh and anyone interested, here's a compilation of what I filmed last year:

|

| |

Last Edit: Sept 21, 2016 7:51:56 GMT by mikeyp247

|

|

|

|

|

Sept 21, 2016 7:56:34 GMT

|

Typical castor is 3 to 5 degrees on cars, so i wouldn't go to the effort of flipping it as I don't think you need as much castor as the flipped steering unit would let you have. I'd have thought 5degrees-10 degrees would be fine with the axle in the existing position and I'd of thought your steering link bar would still have plenty of ground clearance. Could you just warm the box section up with a blow torch and use a big shifter to bend it to the correct angle? Then when your happy they are both twisted the same angle, weld a bit of gusset in to keep it in position and support it? Forgive my terminology, but do you mean heat the cross member holding the steering 'tube' and bend it down? My thinking to drop it as low and inline as possible would be to minimise left/right steering input and create as much rotational input as possible - if that all makes sense...? Also, you say "both" - do you mean the steering 'tube' and the axle? The actual steering assembly is held in place to a bracket with one large bolt and has sponge 'suspension' to allow some tilt. I'll take a picture later, but a straight invert of the axle would be easy and if i was to move it, I would 'simply' need to relocate this bracket and the assembly would bolt back in. |

| |

Last Edit: Sept 21, 2016 7:57:40 GMT by mikeyp247

|

|

steveg

Posted a lot

Posts: 1,586

|

|

Sept 21, 2016 8:33:06 GMT

|

I think if you flip the axle over the ackerman effect you get on the steering will be affected. I can't really explain it properly so it might be easier to google it. It's all to do with where the steering arms attach to the pivoting parts attached to the axle, on karts there called the stub axle. I'm not sure how badly it will affect the steering but it will either steer very violently or not very well at all. Putting the steering arms behind the axle will make the steering work back to front as well. Steer right and it will go left etc. Castor is what you to keep it as stable as possible. On your side view picture the stub axle pivots are at 90 degrees to the ground. To add caster you need to rotate the tops of the pivots backwards slightly. What you hagve here is a huge amount of castor, about 45 degrees. i1174.photobucket.com/albums/r608/Mike_Phillpott/MSturnedSR/steering%202_zpsujkjq8tm.jpgI was thinking of different ways to do the kart I am building and just tilting the steering column back was the easiest option. I haven't altered the castor as it's only going to be going at walking pace. |

| |

|

|

|

|

|

Sept 21, 2016 9:30:43 GMT

|

Typical castor is 3 to 5 degrees on cars, so i wouldn't go to the effort of flipping it as I don't think you need as much castor as the flipped steering unit would let you have. I'd have thought 5degrees-10 degrees would be fine with the axle in the existing position and I'd of thought your steering link bar would still have plenty of ground clearance. Could you just warm the box section up with a blow torch and use a big shifter to bend it to the correct angle? Then when your happy they are both twisted the same angle, weld a bit of gusset in to keep it in position and support it? Forgive my terminology, but do you mean heat the cross member holding the steering 'tube' and bend it down? My thinking to drop it as low and inline as possible would be to minimise left/right steering input and create as much rotational input as possible - if that all makes sense...? Also, you say "both" - do you mean the steering 'tube' and the axle? The actual steering assembly is held in place to a bracket with one large bolt and has sponge 'suspension' to allow some tilt. I'll take a picture later, but a straight invert of the axle would be easy and if i was to move it, I would 'simply' need to relocate this bracket and the assembly would bolt back in. I meant the actual box section that connects to the steering tubes on either end of the beam axle. But looking at it now, it might be better just to drop the entire beam axle complete with steering components, twist the axle to give the correct castor and weld back on but it depends on how it's attached, are you going to keep the suspension or are you going to get rid of it? |

| |

|

|

|

|

. BUT the weight of it, it's yet to be constructed body, and me will still freewheel fairly nicely I think

. BUT the weight of it, it's yet to be constructed body, and me will still freewheel fairly nicely I think  . I need to work on the braking system before I can test that.

. I need to work on the braking system before I can test that.

. BUT the weight of it, it's yet to be constructed body, and me will still freewheel fairly nicely I think

. BUT the weight of it, it's yet to be constructed body, and me will still freewheel fairly nicely I think  . I need to work on the braking system before I can test that.

. I need to work on the braking system before I can test that.