|

|

|

|

|

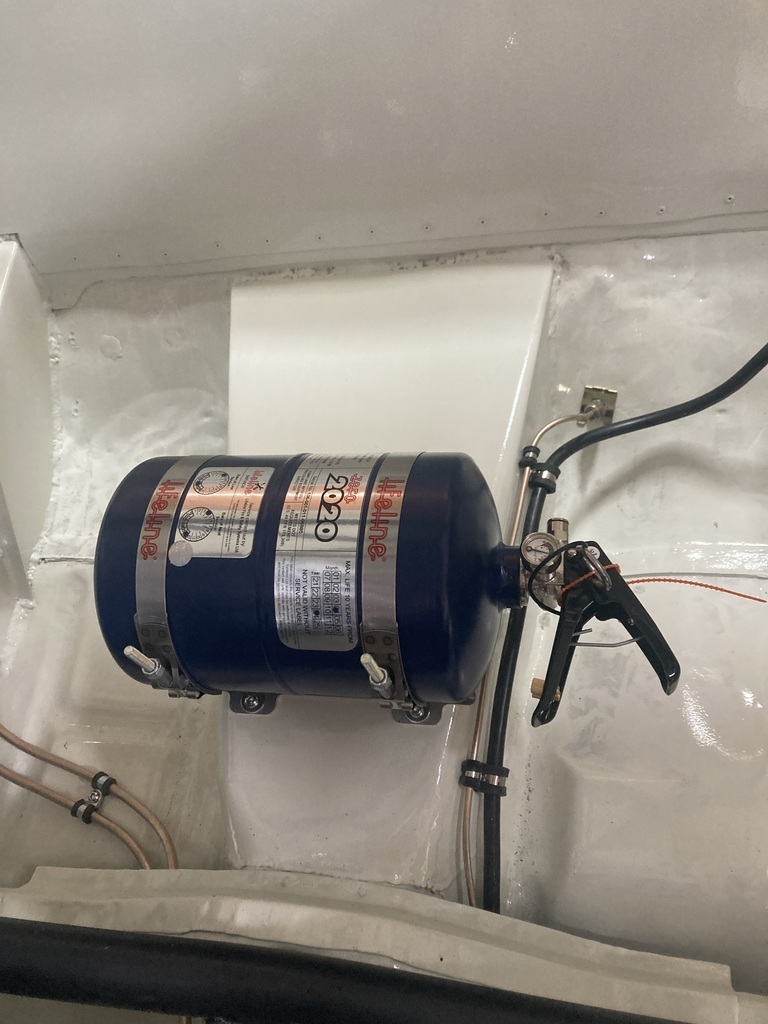

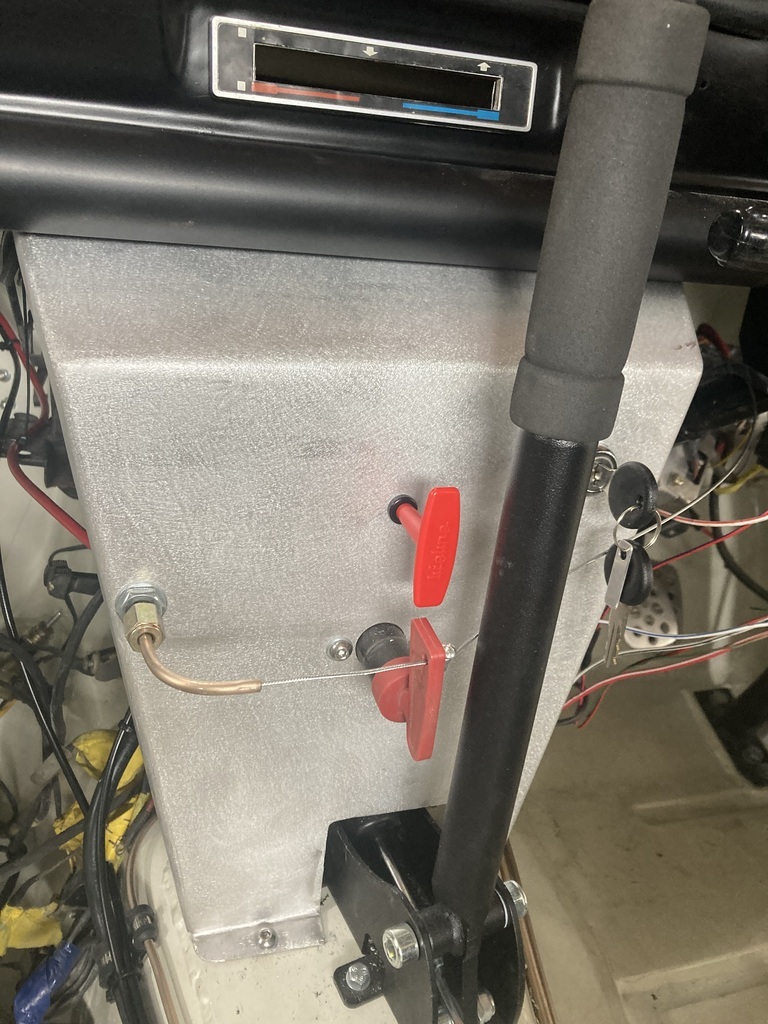

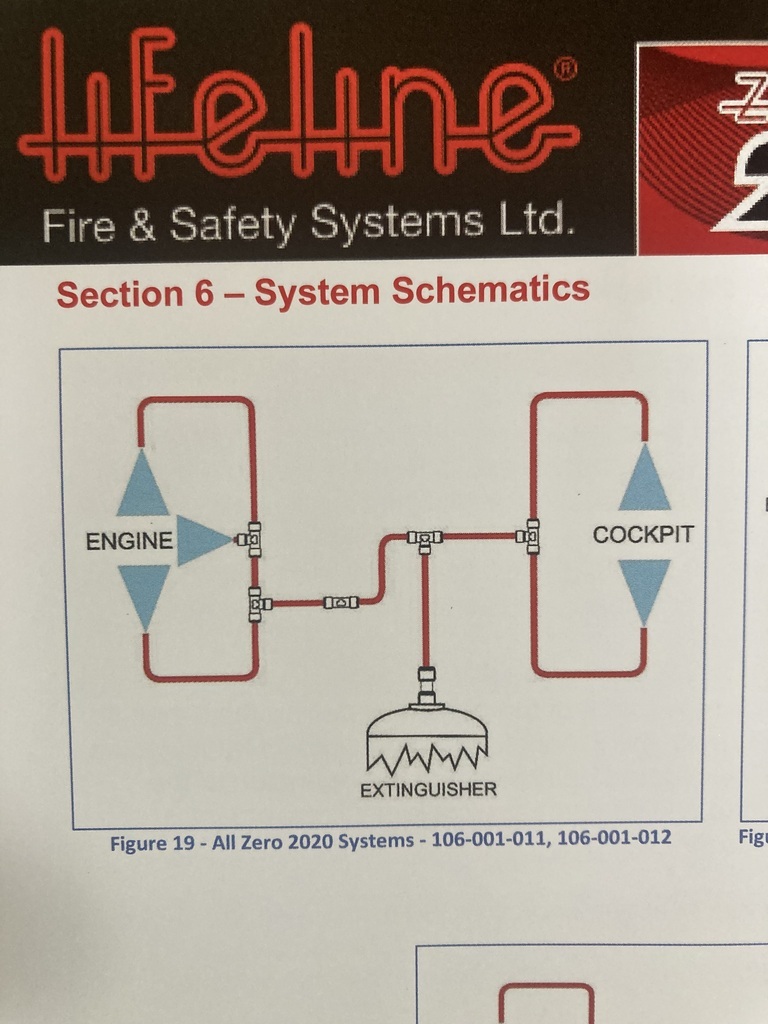

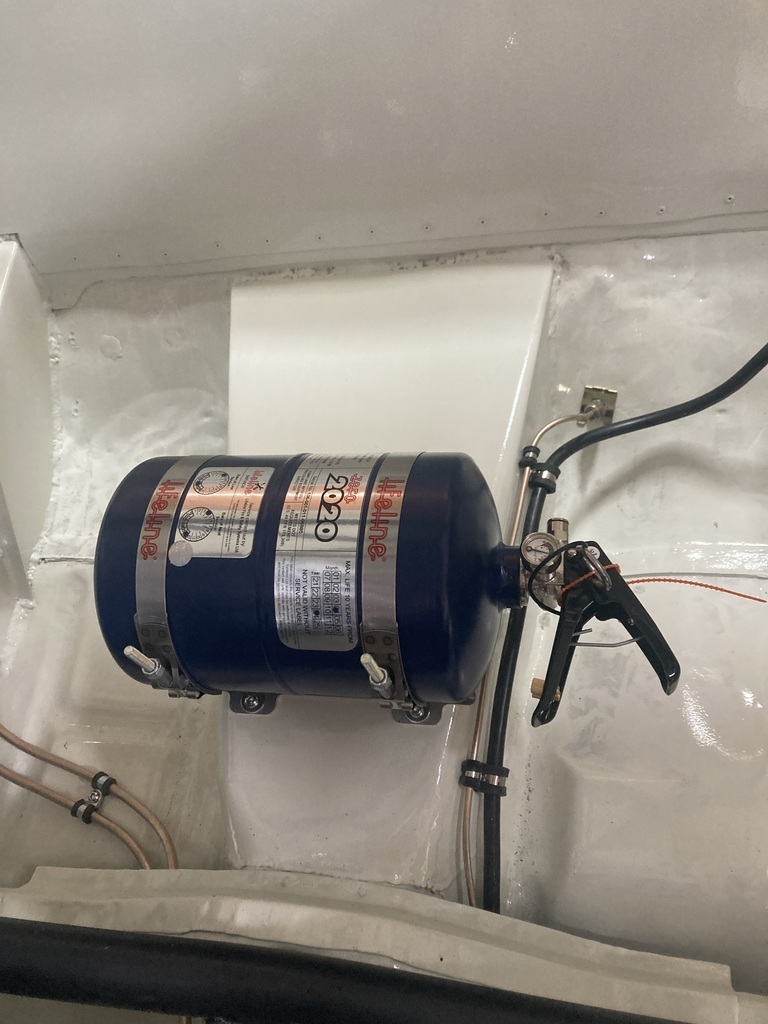

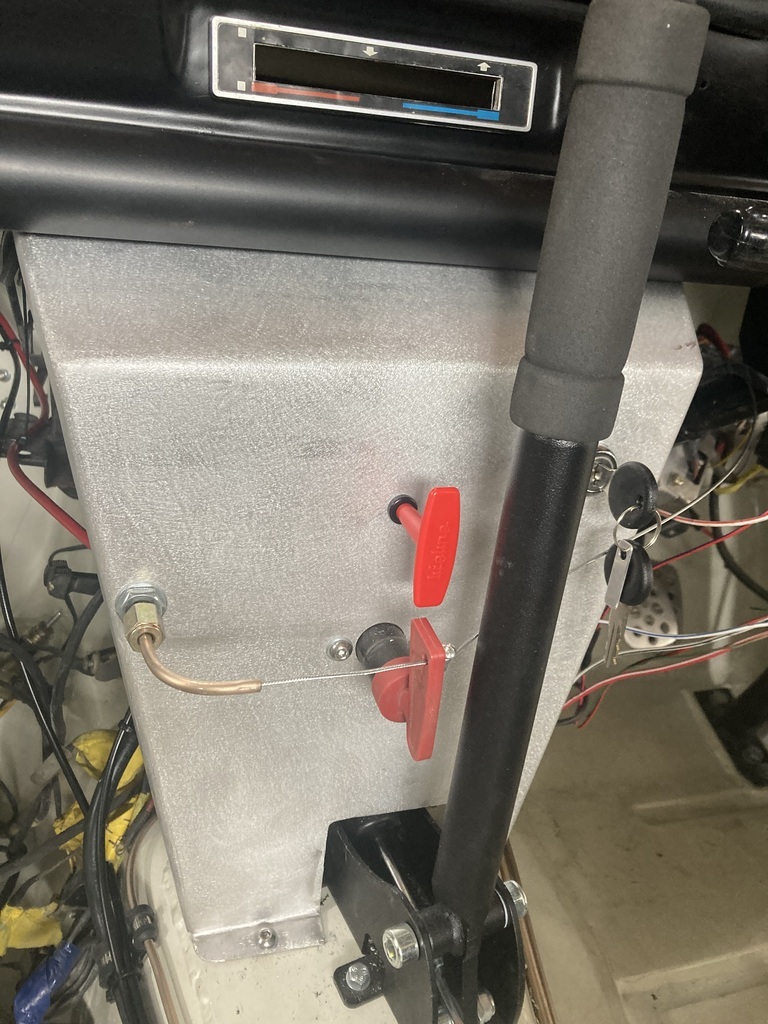

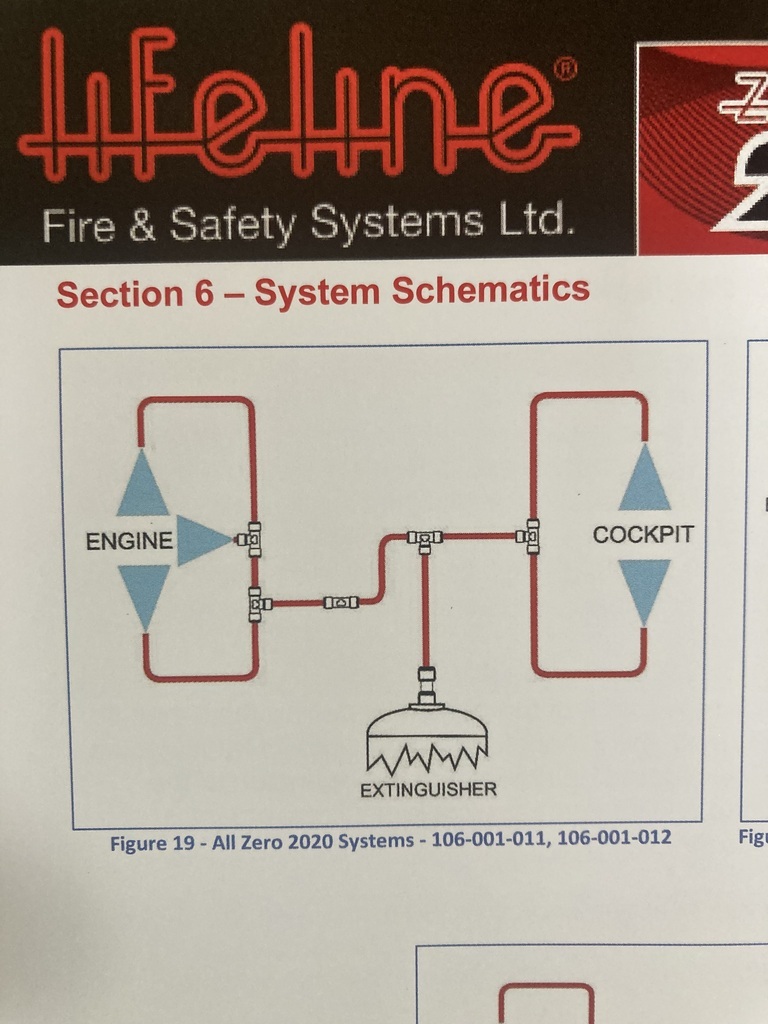

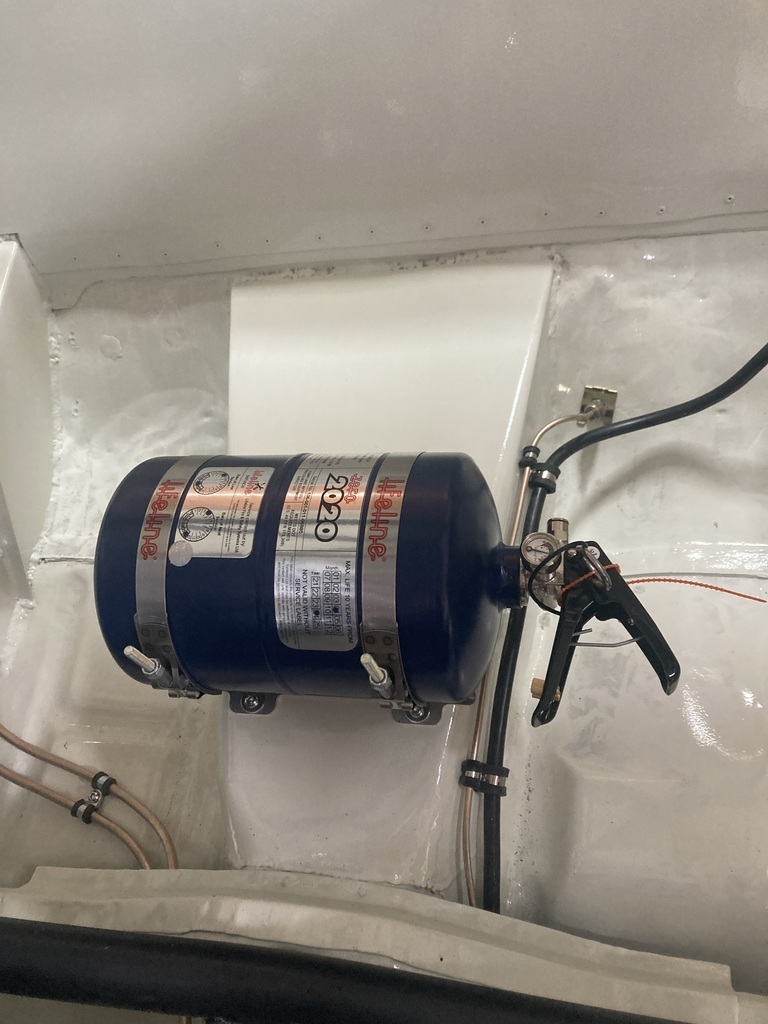

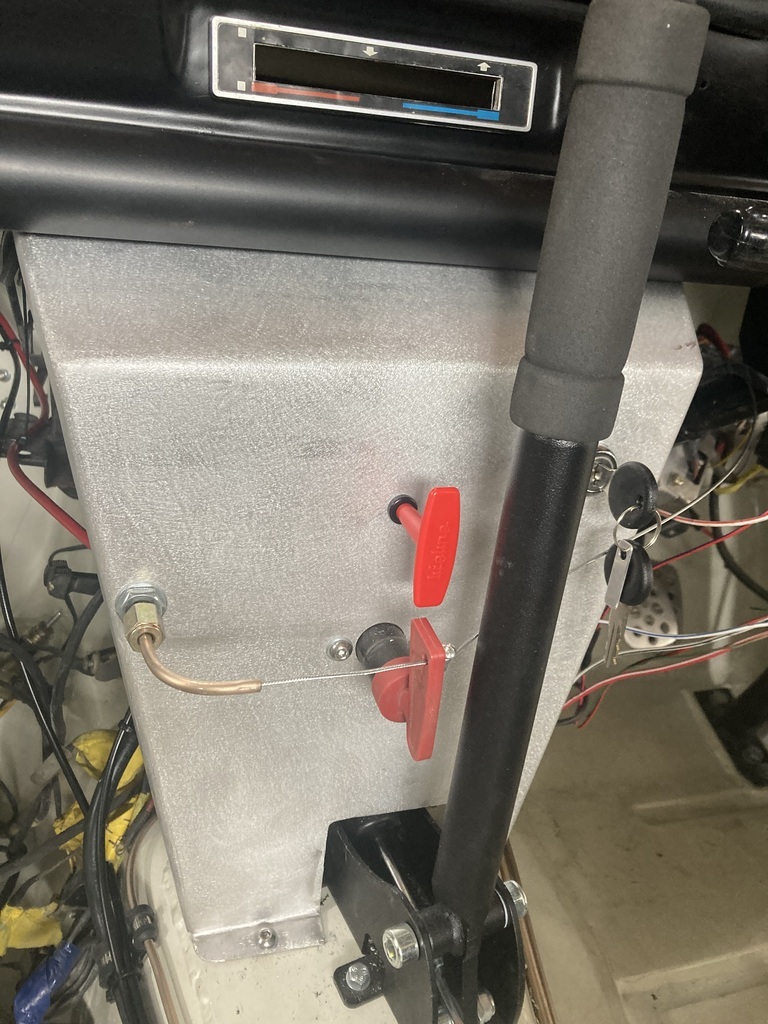

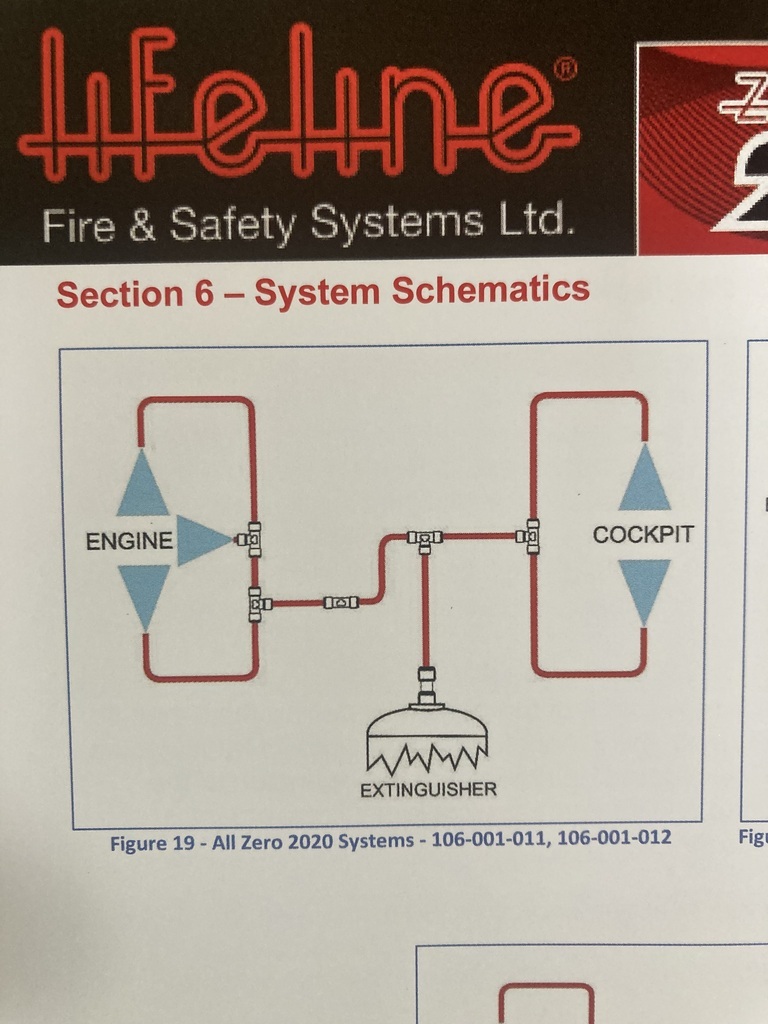

Today I continued with the fuel tank. I made a brace for the return pipe and welded it on. Apparently, no photo. I removed the outlet from the tank. It was originally about 14mm, it’s now 12mm  There was a rattle inside the tank. I assumed the sender had fallen apart. The sender mounds from the bottom of the tank with a rubber seal and is mounted in a bayonet style. With ethanol now in fuel and the sender having never worked, it can go. A baffle was loose inside so I just welded it to the side to stop it rattling  Tacked a plate on  Then tig welded it in place  I then bunged all the holes and filled it with water to check for leaks  Only one leak luckily, but unluckily, it was behind the brace I’d just welded on  Fortunately another pass with the tig sorted it. I then left the tank out in the sun to dry. So I turned my attention to the plumbed in fire extinguisher  This has to be mounted within the roll cage so the diff tunnel seemed as good a place as any.  The clever people out there will notice I have not fitted the straps the hold the bottle so I had to unbolt it again. Those that didn’t notice are as daft as me  And tank mounted  The external pull cable was mounted along with a sticker  The internal pull was fitted in the new switch panel. It has to be next to the electric cut off and accessible  The cables were then run back to the bottle and the solderless nipples fitted with 10mm free play so the scrutineer can see the cables move without setting off the extinguisher  The nozzles must be fitted like so  So I fitted one each side under the dash    I didn’t fancy running any pipe or making brackets for the engine bay so I left it there. As a quick job before I went in, I thought I’d fit the exhaust to see how far off it was    Miles apparently. So I cut the manifold and exhaust up to raise it 2 1/4”.  This sits better  This secondary pipe is now miles off  |

| |

|

|

|

|

|

|

|

Jun 10, 2024 11:17:13 GMT

|

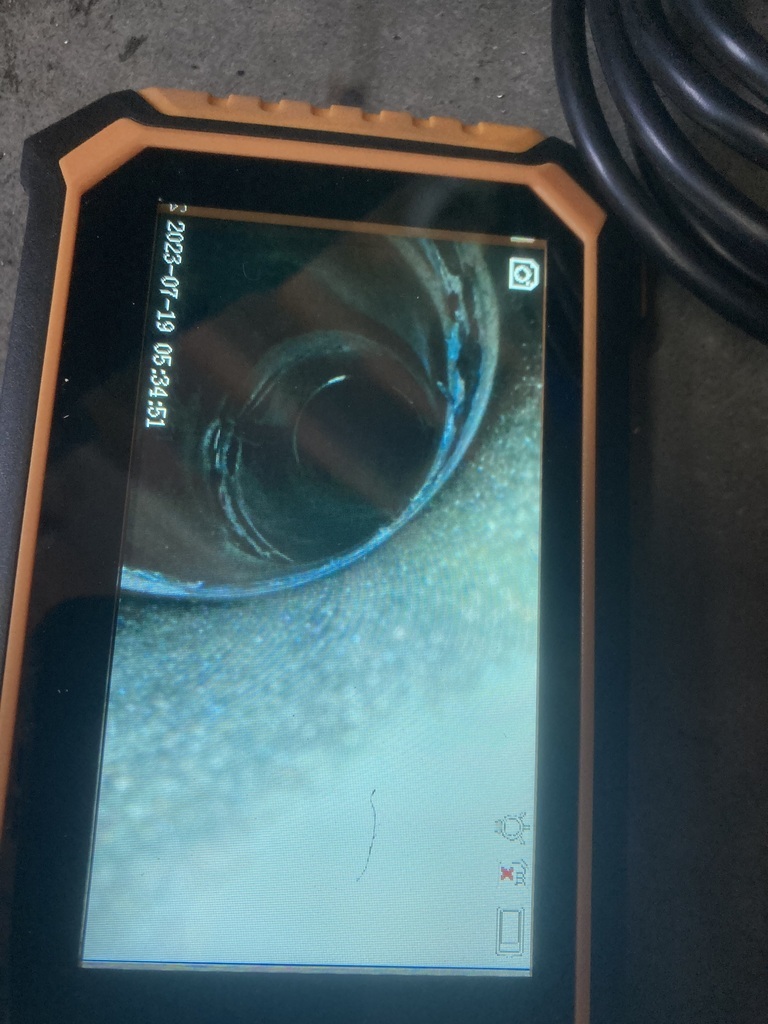

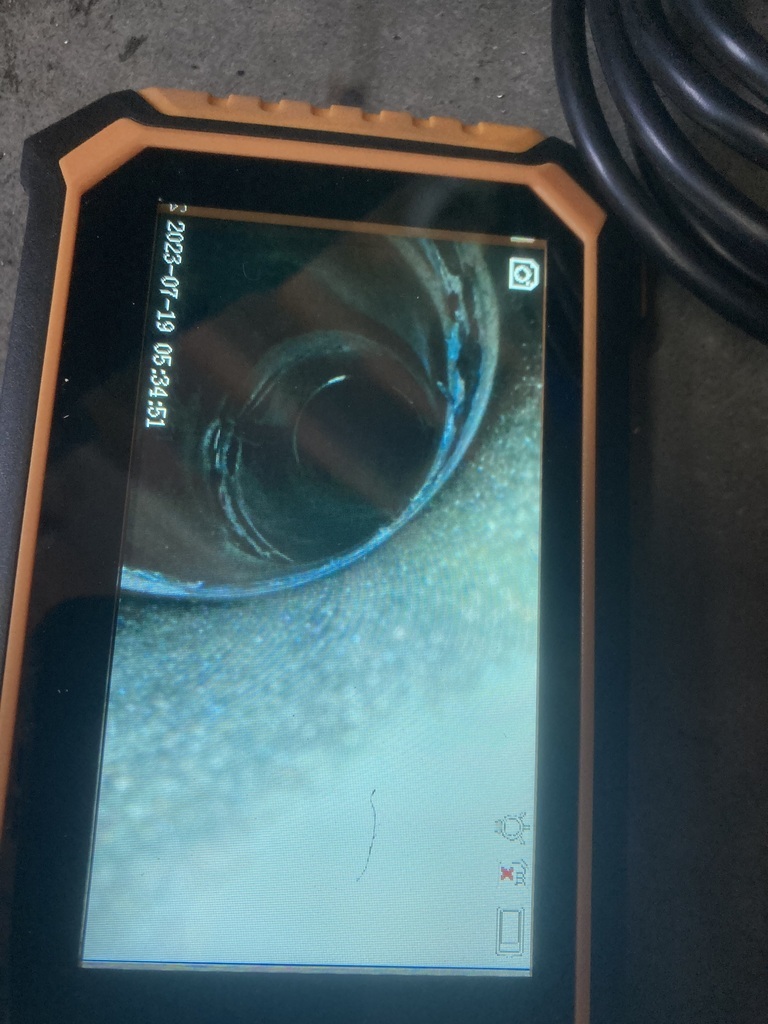

Another couple of hours in before work as I’m on call again. To get the secondary pipes to line up  I cut a slit in the upper section to twist and bend it over  I didn’t want to cut all the way through this section as it’s close to the other secondary pipe so I would not be able to weld it back up without the possibility of leaving a leak. Bending and twisting wasn’t enough so I made another incision  I then twisted the bend slightly and tacked it back on  The tip slit had now opened up by about 5mm  So I had to make an infill sliver  I even tried it back on the car before jumping in and fully welding it    With it ll still in the right place, I welded it up fully with the mig  I used my endoscope thingy to have a look inside to see how it had welded (cr4p photo)  With good penetration and no dingle berries hanging inside to interrupt flow, I decided to pointlessly linish the welds down. We’ll, the bits I could reach anyway  And all back on   I can still split the secondary pipes from the primaries, not that I need to as the manifold goes in complete  I’ve ordered a small section of 58mm ID exhaust pipe to make a joiner on to the exhaust system, so that should be a job for next weekend |

| |

|

|

|

|

|

Jun 15, 2024 18:54:35 GMT

|

Not much done today. The sleeve for the exhaust turned up. I needed to cut a wedge in it as the manifold and exhaust don’t line up. It then got tacked on  The keener eyed amongst you will notice the wedge looked like it was cut by a blind man. It was . I did not have my glasses on. As the exhaust is stainless, I thought I would tig it together. So I did. Badly. When I tried to refit the exhaust, it wouldn’t fit the manifold as somehow the sleeve had shrunk. I put a taper on the piece of exhaust I had cut off and hammered it in. Whilst trying to fit the exhaust I dropped it and dented the silencer 😡. I then called upon the assistance of The Younger to help fit it, and he learned what it was like to help your father to hold something for him in the 1980’s 😁. Lots of shouting. But it went on.  As I started welding the sleeve on, one of the tacks broke. This meant things moved and now the exhaust is hanging low by about 10mm. I was too annoyed with the whole thing to continue so I moved on to the petrol tank. If it annoys me too much, I’ll put the grinder through it and mig it back up. Before the petrol tank went back in, I drilled a hole for the wiring loom so I could hoover up the swarf  Then the tank went back in after a bit of primer was put in where I welded last week  I’m not repainting the tank. It will stay like that. I then made a start connecting up the pipes, I just need to mount the low pressure pump tomorrow. |

| |

|

|

|

|

|

Jun 16, 2024 17:07:11 GMT

|

Not a lot done again today. I had a punctured tire on the Trafic so I took that to my bother’s garage to get it fixed. Took it in the cortina so had a nice spin too. Yesterday, I forgot to add that I have removed the injectors to take them to be cleaned   They really didn’t want to come out, but they finally gave up the fight. The engine hadn’t run for 4 years and then I ran it on 4 year old fuel so it’s worth getting them checked. I also want to fit new o rings as I don’t want any leaks. After getting back and after mowing the lawns, I finished mounting the low pressure fuel pump in the boot. I also removed its filter to give it a clean beforehand.   And also fitted a fuel tank breather  That means the fuel system is complete (except for the fact I’ve dismantled the throttle bodies) |

| |

|

|

|

|

|

Jun 20, 2024 11:29:19 GMT

|

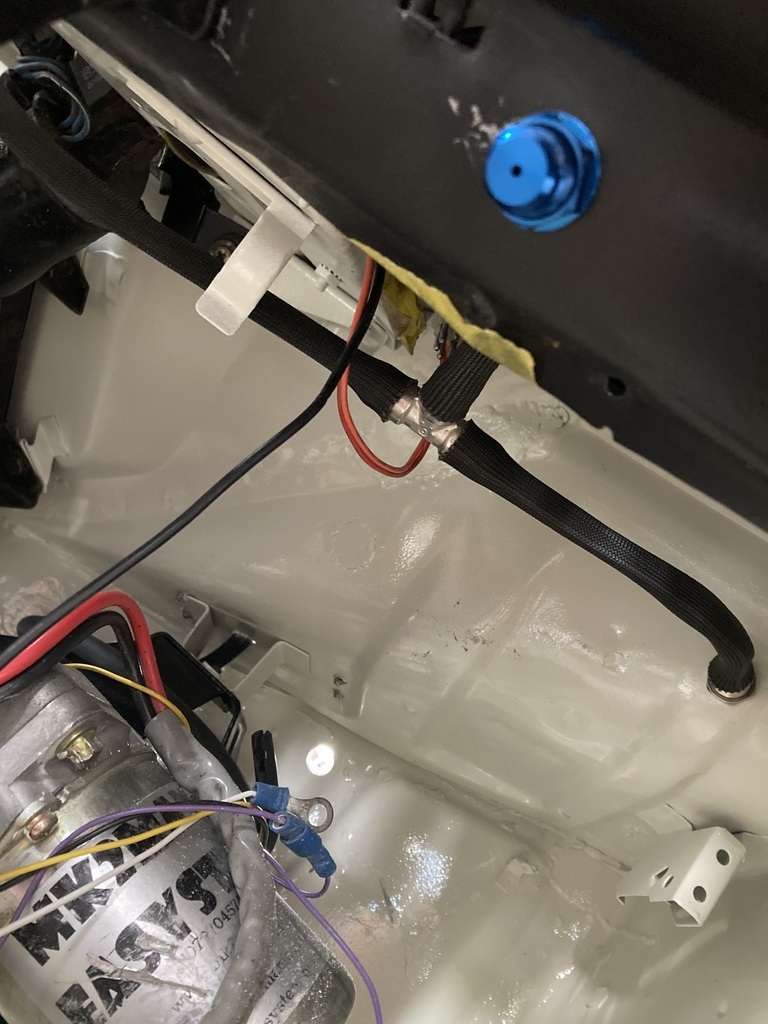

I was a day off work yesterday, but nothing got done as I was helping Mrs Jonsey’s sister and family move house. But I’m own call today, so I got a couple of hours in. I didn’t want to get too dirty so I thought I’d continue with the plumbed in fire extinguisher. I ran the pipe from the bottle, through the rear seat stiffener and up behind the dash  I haven’t bothered clipping it yet as I’ll need the assistance of one of the Youngers. I thought long and hard what way to plumb the pipe into the engine bay. The kit came with one bulkhead fitting to get into the engine bay. This would mean it have to have a pipe going along the bulkhead. I thought this would look rubbish, so I have ordered another bulkhead fitting to bring a pipe into each side of the engine bay. So I drilled the bulkhead on the passenger side, made a bracket for the nozzle to mount off a strut top bolt and ran the pipe  A bracket for the driver side was then made, along with one for the rear of the engine bay and the pipe ran.  I might paint the brackets black. I might not. And that was that. To much thinking meant not much working. |

| |

|

|

teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,125

|

|

Jun 20, 2024 11:37:44 GMT

|

Too much thinking meant not much working. You can’t underestimate the importance of contemplation time, Phil. |

| |

|

|

|

|

|

Jun 20, 2024 18:22:52 GMT

|

Too much thinking meant not much working. You can’t underestimate the importance of contemplation time, Phil. As is evident in this thread, thinking first isn’t usually my cup of tea. The thought of having to buy extra pipe was a major factor today though. |

| |

|

|

|

|

|

Jun 23, 2024 18:40:20 GMT

|

No progress today as I’m on call, but I did do a tiny bit yesterday. See this coil of braided sheathing?  It is slid over all the fire extinguisher pipes to stop the heat of a fire damaging them, apparently. Now if the the pipe is going to be damaged by heat (it is aluminium covered in plastic), then it seems to me to be the exact place where you would want the fire extinguisher to squirt. So the car and myself would probably be better off without it. But rules are rules, so I started fitting it.  As you can see I also fitted P clips and drilled the tunnel. No nuts fitted yet due to the continuing short arm problem. Whilst doing this my brother sent me a couple of photos of a cool car (Toyota Corolla with 4age?) It was at the motor clubs auto test at Pembrey Motorsport Centre.   So I thought, stuff working on the car, I’ll go and have a nose at that and watch some cars doing some skids. The younger and myself jumped in the Cortina but it was all over and the car gone by the time we got there 😩. But it wasn’t a wasted journey as I came back with this lot for £50.  A spare head with all valves and springs, a rocker cover, swirl pot, exhaust manifold, dry sump tank, breather tank and some other bits and bobs. In other news, on Friday I had a call from the injector cleaning people to inform me that 2 of the injectors are not working properly. They are injecting the correct amount but it is giving more of a stream of fuel rather than an atomised spray. More money to spend there then😩 |

| |

|

|

|

|

|

Jun 23, 2024 20:09:17 GMT

|

|

Excellent work as always. So much has happened in a short space of time. Everything looks so neat and tidy 👍🏻

|

| |

Opel Commodore A Coupe

Opel Rekord C Coupe

Opel Rekord C Saloon

Vauxhall Magnum Coupe V8 (Magnumania)

Mk1 Scirocco GLS

Mk1 Scirocco GLS (early chrome bumper)

Corrado G60

Mk1 Cortina 2 door Pre Airflow

Mk2 Escort 1300 2 Door

VW LT35 Tipper Truck

BMW 320D E91 Tourer

|

|

jimi

Club Retro Rides Member

Posts: 2,223

|

|

Jun 23, 2024 20:38:28 GMT

|

|

|

| |

Last Edit: Jun 23, 2024 20:39:53 GMT by jimi

Black is not a colour ! .... Its the absence of colour

|

|

|

|

|

Jun 24, 2024 16:27:47 GMT

|

Excellent work as always. So much has happened in a short space of time. Everything looks so neat and tidy 👍🏻 Thanks Mr Couper. It’s getting there slowly. |

| |

|

|

|

|

|

Jun 24, 2024 16:28:25 GMT

|

|

|

| |

|

|

|

|

|

Jun 26, 2024 11:10:55 GMT

|

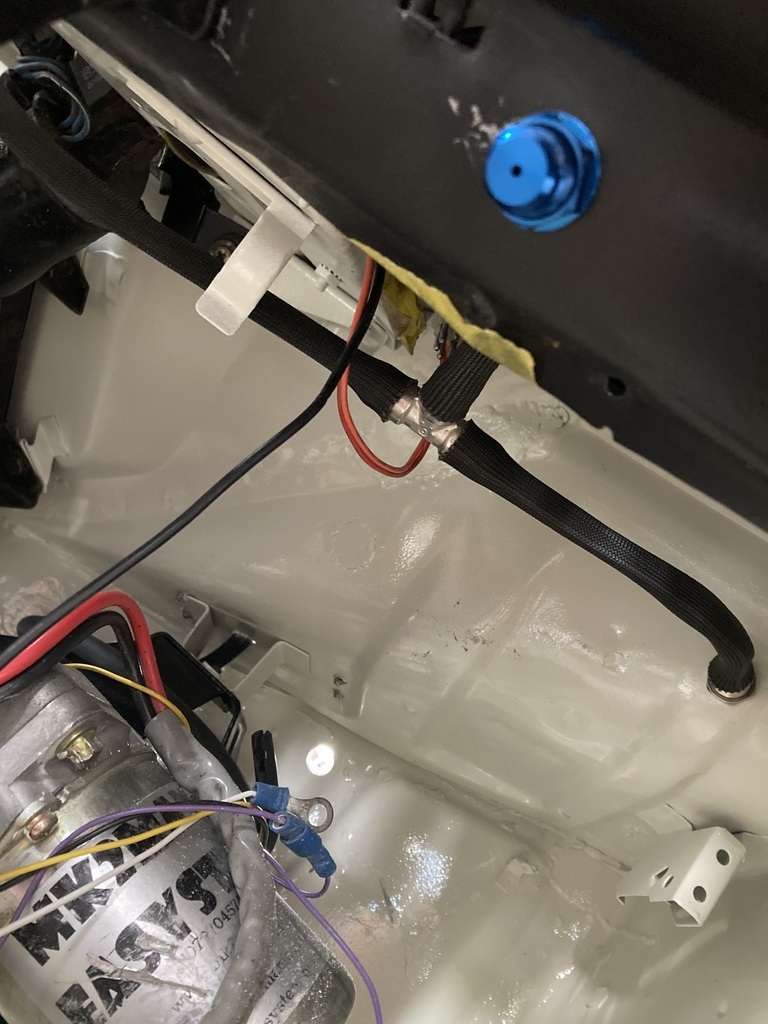

I’m on call again, slightly tired as I took The Younger to see Foo Fighters in Cardiff last night and the weather is glorious. So I’m up early and in the garage. But first I went to collect my Trafic from my brother’s. I’d borrowed his car to go to the gig as the van’s gearbox was howling and I didn’t want to risk breaking down. He used my van to go to a machine shop and the gearbox locked up. It’s still driving but a new box is now required. Fire extinguisher plumbing was finished and heat sleeving fitted      I’ve bought an air/fuel gauge and a mounting bung, so I drilled a big hole in the manifold  And then used my new Lidl welding helmet to snob it on   The helmet is pretty good for £23. I only bought it as the mig set is at one end of the garage and the tig is at the other and my old one is always in the wrong place. Lazy or what? Lambda sensor fitted  More on the weekend |

| |

|

|

ChrisT

Club Retro Rides Member

Posts: 1,670

Club RR Member Number: 225

Member is Online

|

|

Jun 26, 2024 21:13:28 GMT

|

|

Shouldn't that sensor been mounted at a downward angle?

|

| |

|

|

|

|

|

Jun 26, 2024 22:48:37 GMT

|

Shouldn't that sensor been mounted at a downward angle? |

| |

|

|

|

|

|

Jun 26, 2024 22:50:11 GMT

|

|

I’ve absolutely no idea. Perhaps I should read the instructions!

|

| |

|

|

ChrisT

Club Retro Rides Member

Posts: 1,670

Club RR Member Number: 225

Member is Online

|

|

|

|

I’ve absolutely no idea. Perhaps I should read the instructions! I know it goes against the man code to do that but probably a good idea in this case. It's got something to do with allowing condensation to drip off the sensor IIRC.... |

| |

|

|

|

|

|

|

|

I’ve absolutely no idea. Perhaps I should read the instructions! I know it goes against the man code to do that but probably a good idea in this case. It's got something to do with allowing condensation to drip off the sensor IIRC.... I’ll be getting the grinder out then😩 |

| |

|

|

|

|

|

Jun 28, 2024 15:53:35 GMT

|

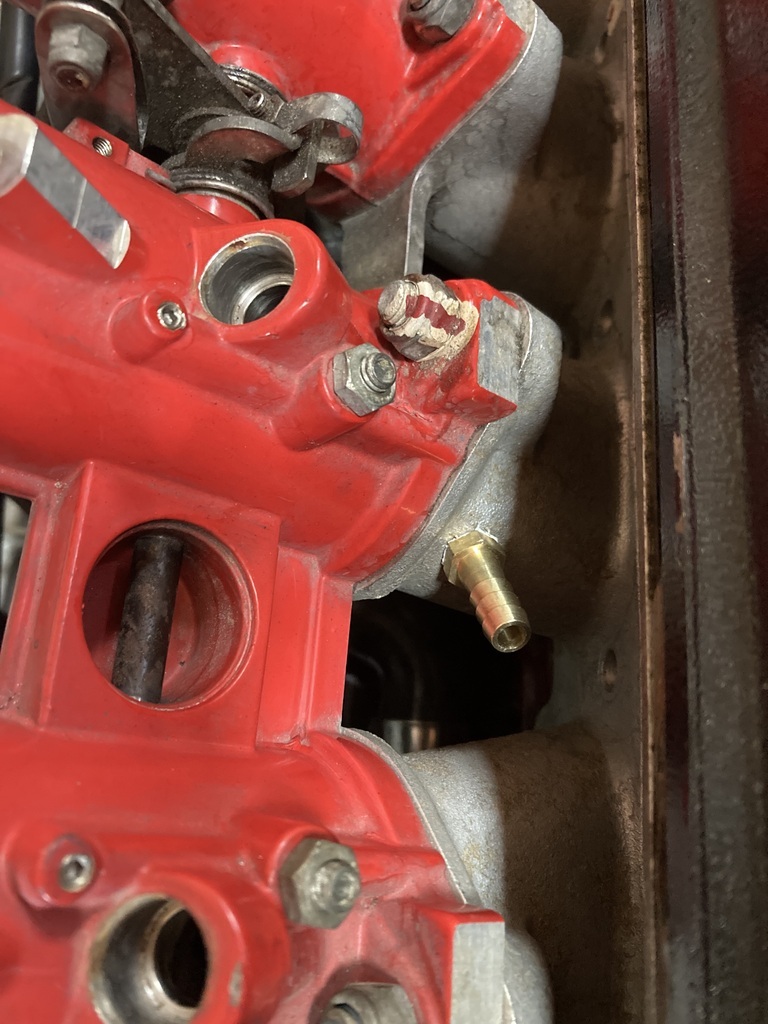

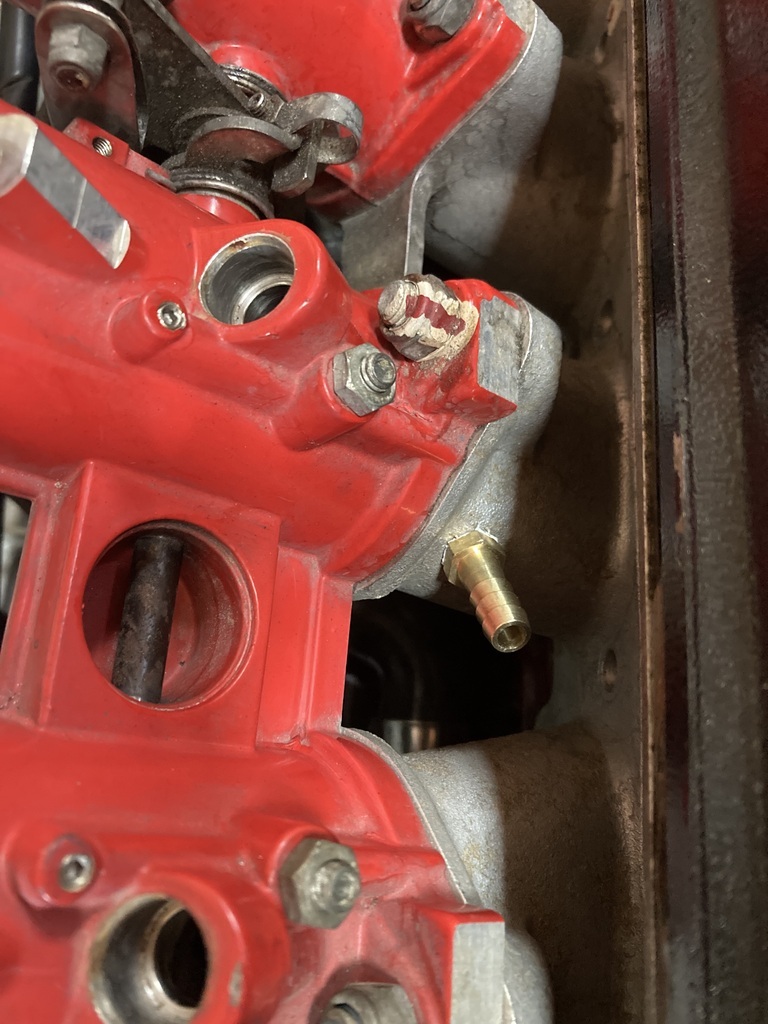

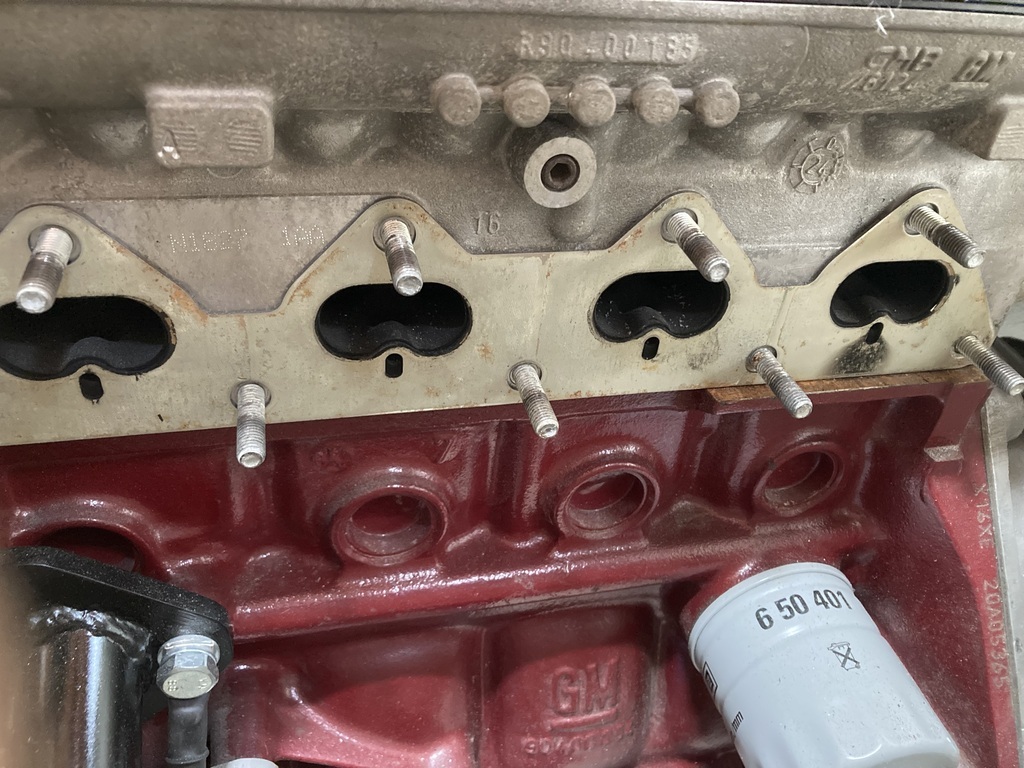

As I worked last Sunday, I’ve got the day off today, so it’s a long weekend. I was out the garage by 9am. First thing to tackle was the lambda sensor. As kindly pointed out by ChrisT, I’d bolsed it up. Boss cut out  Patch fitted  Ground it up and for no reason whatsoever, I put a pretend weld seam back in.  Boss rewelded (badly) to the manifold  I wanted to fit the manifold for good. As I believe all the black paint is going to burn off in seconds one the engine is running, I sanded it off the flange.  Manifold fitted  Lambda sensor in   Exhaust still low  Put the disc cutter through the weld I did last week and jacked the exhaust to where I was happy  Welded and closer to floor.  Drilled the dash (badly) and fitted the oil pressure and coolant temperature gauges. They also got plumbed in too  I was going to fit them in the consul, but decided they would be better higher up. I only had a 48mm holes saw and not 52mm so used the burr to make it the right size. It looks like an angry badger has attacked it. Inlet manifold drilled and tapped for an 8mm barb. This is for the servo pipe.  |

| |

|

|

|

|

|

Jun 28, 2024 16:26:57 GMT

|

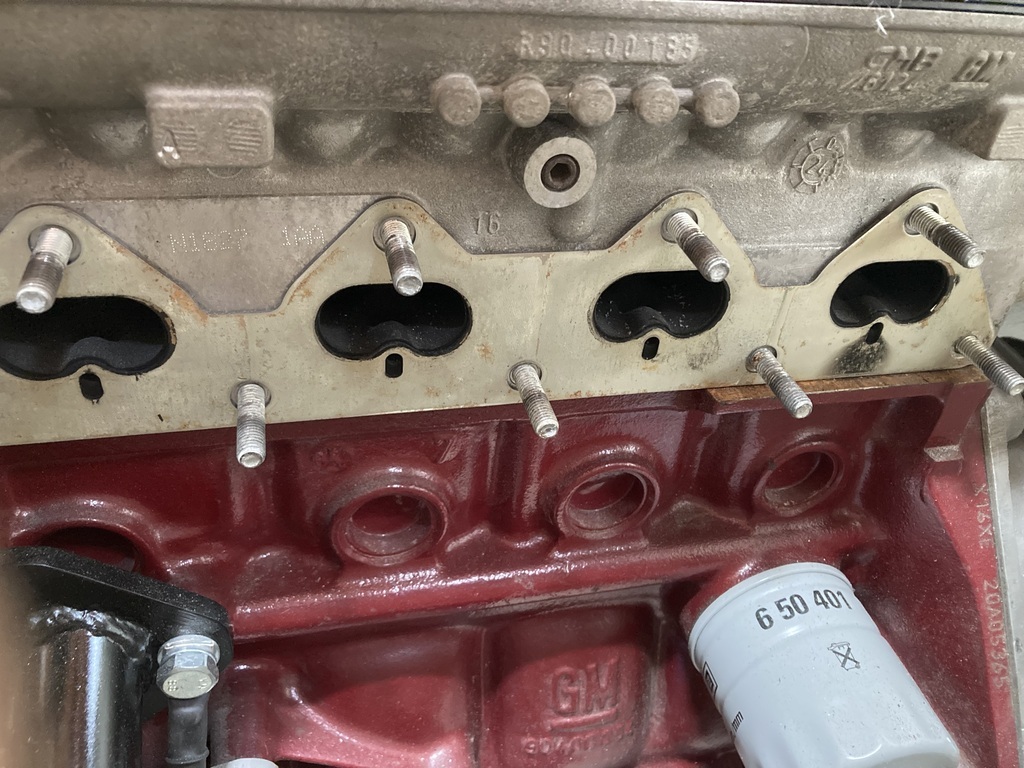

Forgot to mention I ported the manifold to match the new gasket  I then made this out of an old spark plug, an air fitting and a bit of an old lamp stand  The cylinder head has the lumps in the exhaust ports, that I think are for exhaust recirc on a standard car.  The ports are small enough as it is. God knows how it makes 150bhp. So I ground the lumps out.  To stop the cr4p going into the cylinder, before grinding I turned the engine over until the exhaust valve was closed. I blew air down the spark plug hole with my special tool to confirm  After grinding, I then blew out the port with a blow jet, and then opened the exhaust valve with the air down the spark plug just to make sure everything came out. I don’t know if it will make any difference but I can’t see it doing any harm. The gasket was also trimmed to match |

| |

|

|