|

|

|

Feb 22, 2023 11:32:30 GMT

|

|

Nice looking wheels to come!

But will you shave the tyres to reduce their weight or just accept the excess weight and get more use out of them?

|

| |

|

|

|

|

|

|

|

Feb 22, 2023 16:32:20 GMT

|

Nice looking wheels to come! But will you shave the tyres to reduce their weight or just accept the excess weight and get more use out of them? Maybe I could get some part worn tyres :-) At £600 a piece I wouldn't be shaving them! However, I can't get the sizes I want in the Michelin TB5s so I am looking at the Nankang AR1. The price difference is staggering. £2270 for a set of the TB5s compared to £660 for the AR1s.  |

| |

Last Edit: Feb 22, 2023 16:32:50 GMT by nalesutol

|

|

|

|

|

Feb 23, 2023 10:53:41 GMT

|

|

Any other suggestions for road legal tyres?

185/60/R14 or 165/50/R15

275/35/R15

|

| |

|

|

|

|

|

Feb 23, 2023 13:34:34 GMT

|

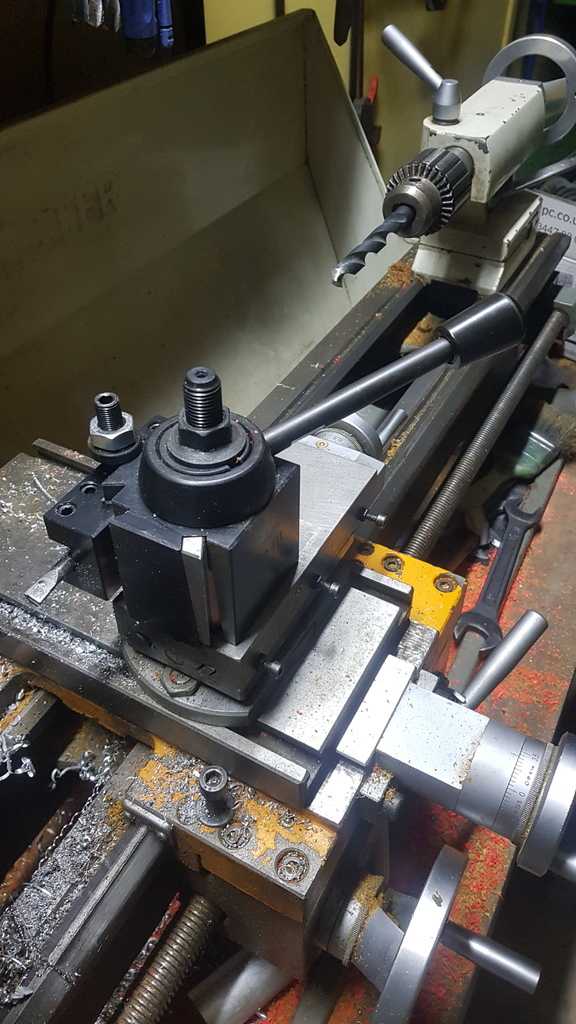

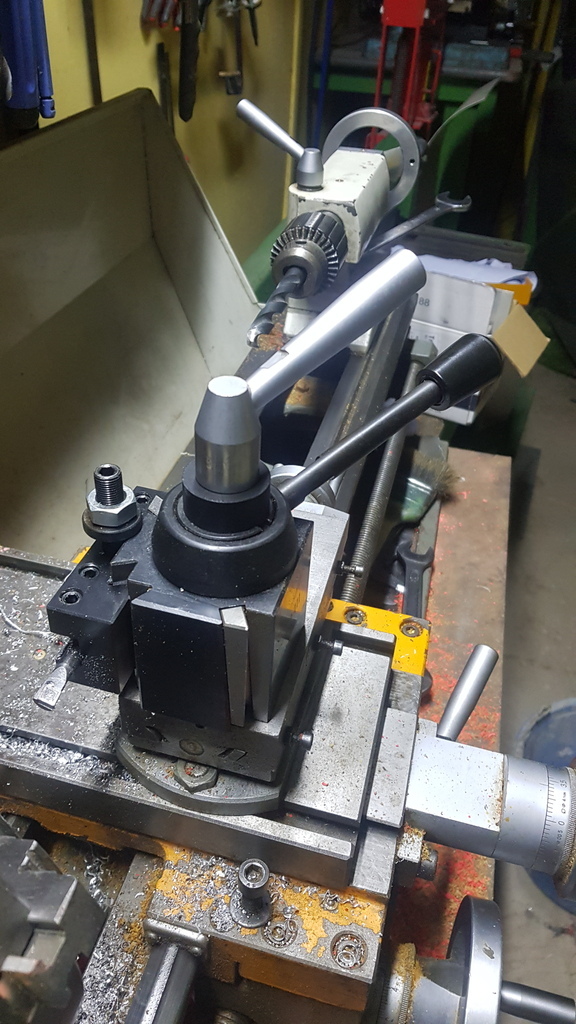

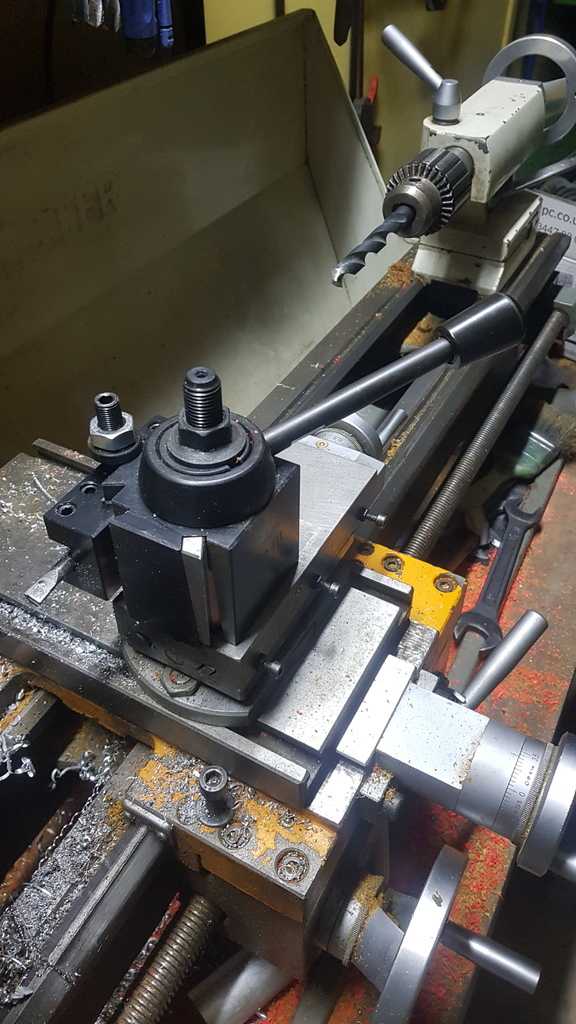

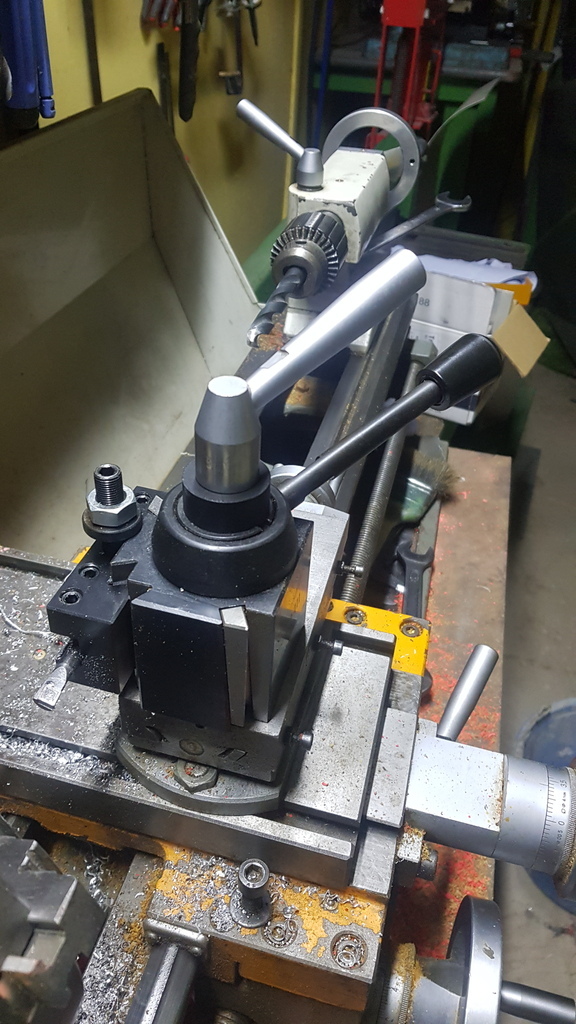

One positive from deciding to get the car electrics sorted has been that I have stopped fretting about it and can get on with other stuff without thinking that I should be working on the car :-) To that end, more mods to the lathe. The new quick change tool post is secured using a nut and spanner but the original used a handle, a much easier way. So I modified the old handle by increasing the thread to M14 and made an aluminium spacer. Much easier now. By fine tuning the thickness of the spacer I was able to keep the handle out of the way.   |

| |

Last Edit: Feb 23, 2023 13:35:02 GMT by nalesutol

|

|

|

|

|

Feb 26, 2023 17:53:47 GMT

|

|

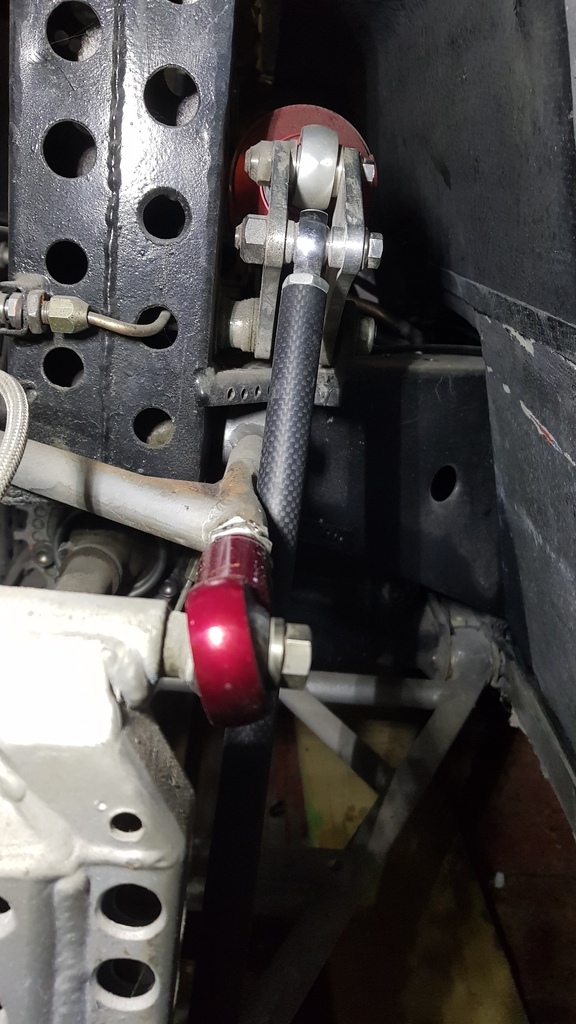

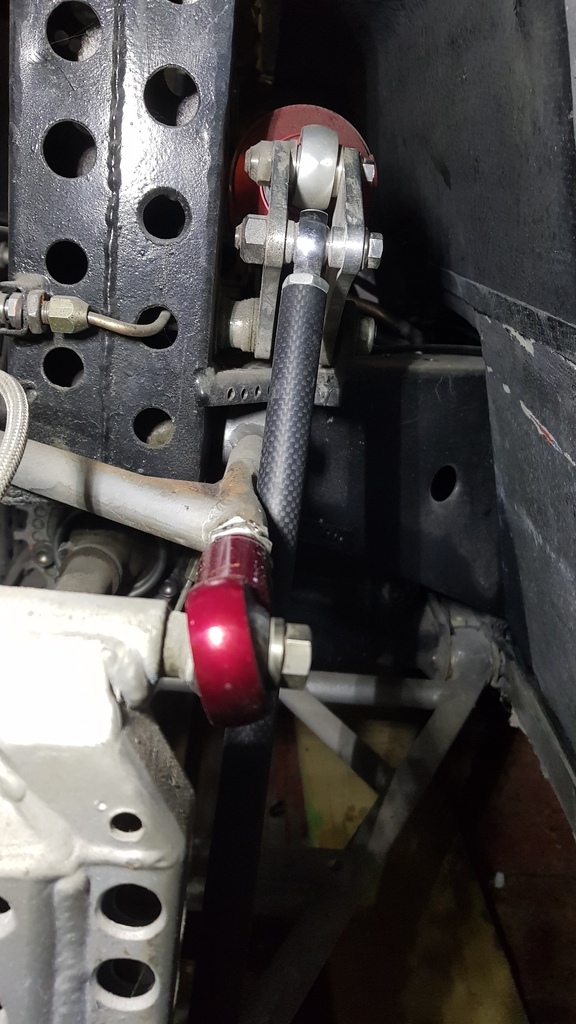

On a bit of a roll now 🙂 Couldn't remember how far I had got with the flappy paddle install. However, scrolling through the Lotus build files I found this and it triggered the old brain cells into action. I built the system myself as the commercial ones are silly money. On the first attempt I used an actuator that was too small (diameter) as I had failed to allow for the area lost to the shaft.

This actuator seems to work OK but the proof will be when we finally fire the beastie up. I hadn't made the steel sleeve for the securing bolt (to prevent the titanium bolt elongating the hole in the aluminium bracket) at the time, hence the movement, it wasn't due to band workmanship 🙂 I have gone down the pneumatic rather than the electric route as it gives a softer kick to the gear lever so less shock to the system.

|

| |

Last Edit: Feb 27, 2023 17:11:42 GMT by nalesutol

|

|

|

|

|

|

|

Man...feels like the old days when I could count on a post a day for this build. Might have to get back on another project of my own cause now I feel like a slacker! Or I could just build a rec room and chill. Edit: I DID buy this nifty LS L33 with not real purpose other than to say I built an LS engine. With a bit of gearing and adaptive engineering it would make one amazing margarita mixer for the wrecked room!  |

| |

Last Edit: Mar 1, 2023 0:15:23 GMT by bjornagn

|

|

|

|

|

|

|

Man...feels like the old days when I could count on a post a day for this build. Might have to get back on another project of my own cause now I feel like a slacker! Or I could just build a rec room and chill. Edit: I DID buy this nifty LS L33 with not real purpose other than to say I built an LS engine. With a bit of gearing and adaptive engineering it would make one amazing margarita mixer for the wrecked room!  :-) Maybe not every day yet, but as soon as the car goes and comes back I will get on with it so there will be frequent updates. They make good coffee tables :-) |

| |

|

|

|

|

|

|

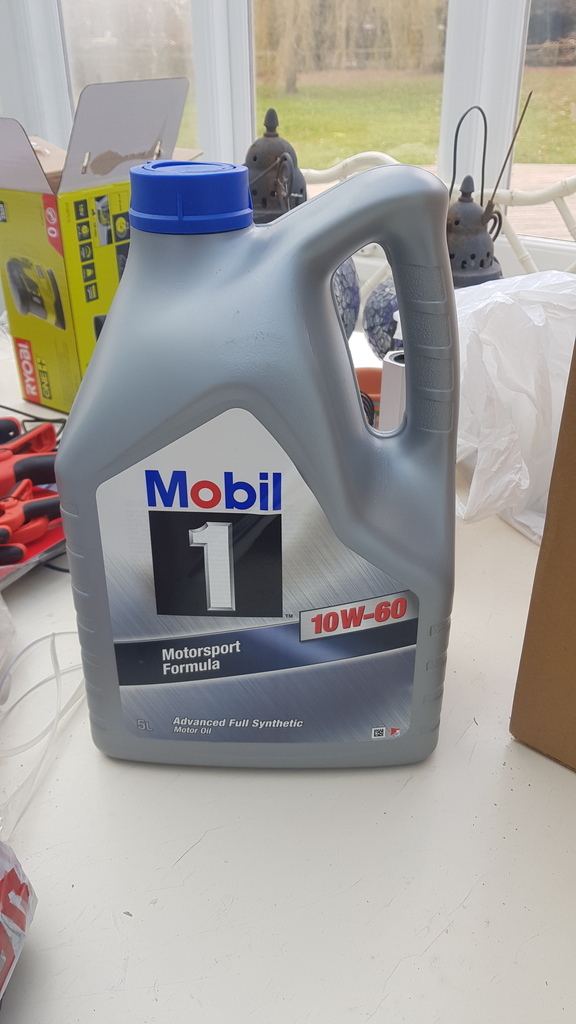

|

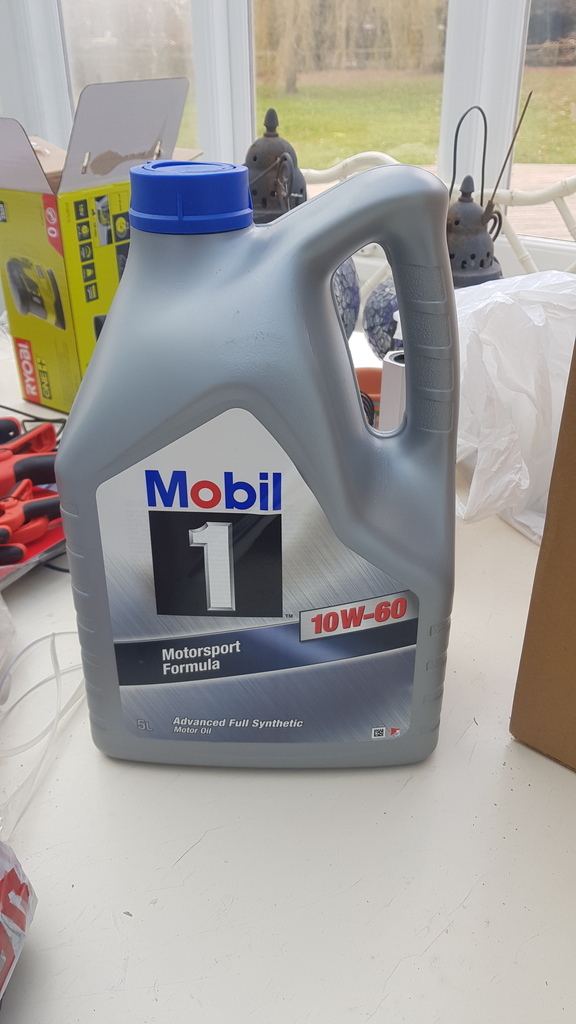

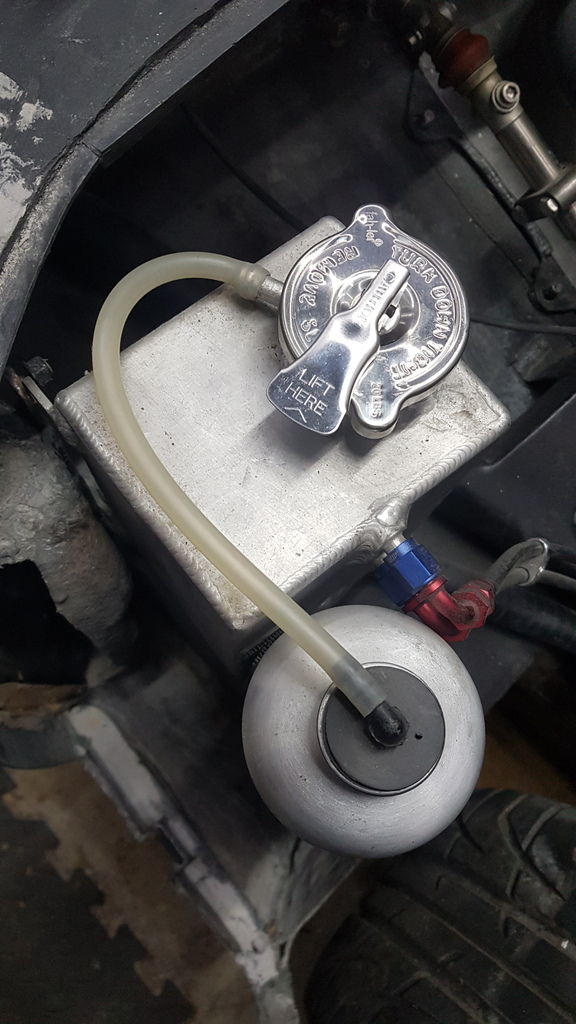

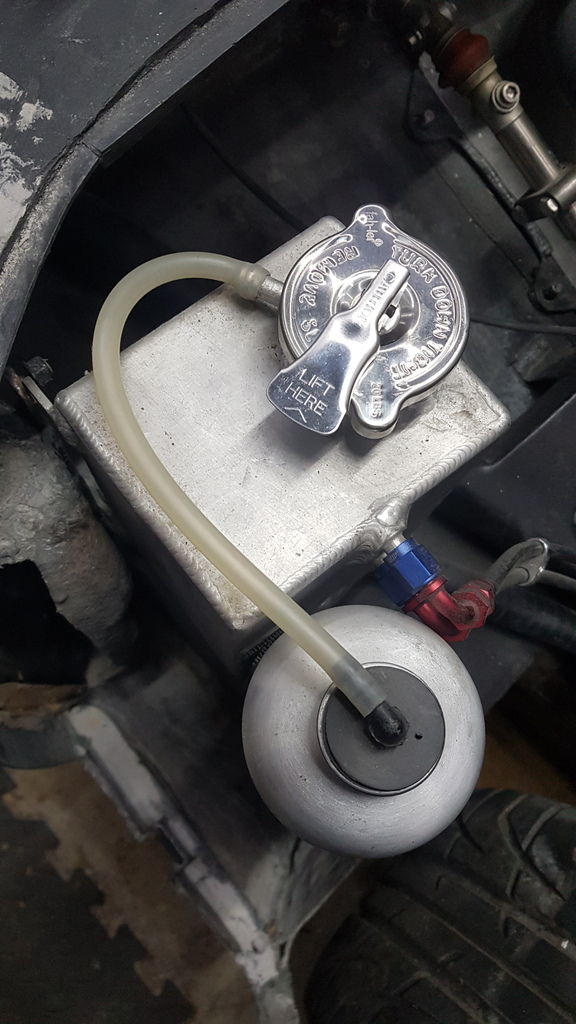

Especially for bjornagn :-) Lots of stuff arrived today. JCS high grip stainless hose clips, engine oil, brake fluid and header tank cap. The cap has a pressure release lever. I know, excess weight :-) However, it was the only one I could find that had a large enough diameter bottom seal. I will just have to get used to it. I was planning to use Mikalor clamps and to that end I bought a load some time ago. However, the JCS clamps are used at GPE where the car is going, are cheaper and less than half the weight, saving over 1.5kg! If they are used on race spec RS200s and 1980s F1 cars they will do me just fine. If they are an issue at high boosts then I still have the Mikalor.    |

| |

Last Edit: Mar 2, 2023 11:54:45 GMT by nalesutol

|

|

|

|

|

|

|

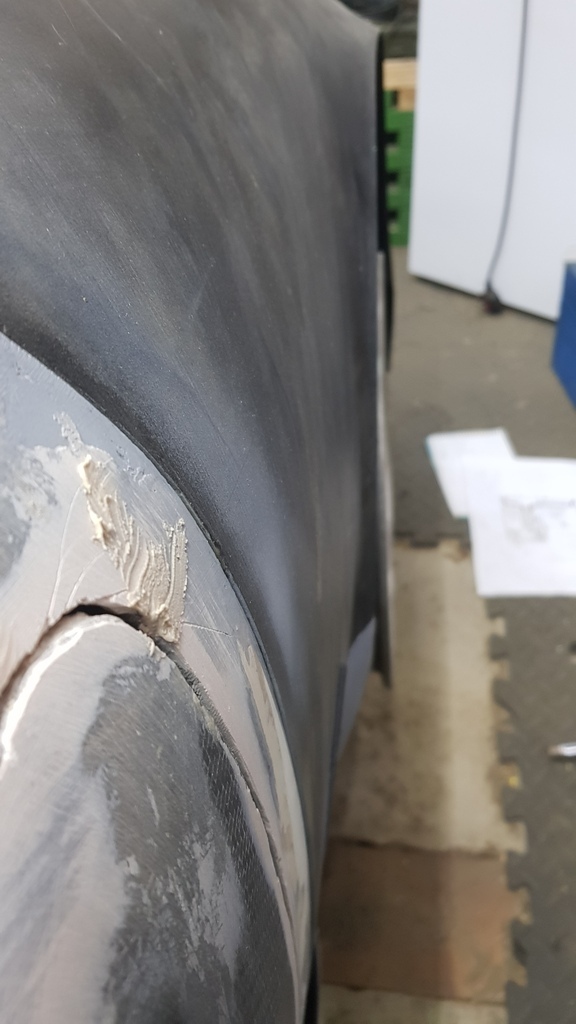

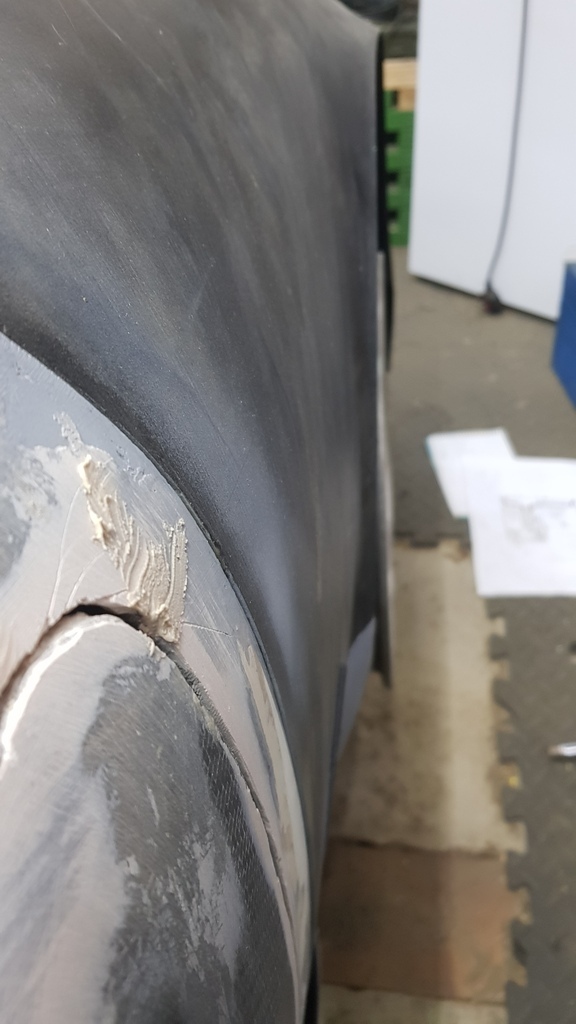

OK, time to man up and sort out the wheels. I have been putting this off for years :-) Fronts: Either 15 x 7 or 14 x 7 Image Wheels 3 piece billet Ultralites. Will depend on final tyre choice. Plenty of clearance.    Rears: A little trickier due to clearance issues. However, on checking with the 15" rim I have, there is JUST enough clearance. So these will be 15 x 10s    With regard to the amount of wheel outside of the hub, 3 1/2" brings the wheel in line with the arches on front and back. However I think that I will go with 3" giving me some wriggle room with spacers if needed. On looking around I revisited the damper push rod. I made these from carbon tube with left and right hand threaded aluminium inserts. There was no clearance to the top wishbone so this was attacked with the wheel of death and strenghened. It is still very tight and I am not happy with the safety issue. If the insert comes out.......... So I am reverting to the original design of steel tubes. I can use 12.7mm 16swg T45 seamless as this will take a 10mm thread, doing away with the need for an insert and giving me more clearance. A bit heavier but a lot safer IMO.  |

| |

Last Edit: Mar 6, 2023 18:55:57 GMT by nalesutol

|

|

|

|

|

|

|

The trouble with taking so long on a project is that you re-visit and re-assess previous work, but this can have a positive side. A case in point are my rear inboard damper push rods. Whilst sorting out wheel specs I kept looking at these rods. As mentioned in my previous post I wasn't happy with their close proximity to the top wishbone, even with the mods. The original rods were steel, but this was before I caught the weight reduction disease. I decided that they were too heavy so made carbon ones with aluminium threaded inserts glued in. Although the glue used was designed for such use I have never been 100% happy. Although most of the forces are in compression, if the glued joints fractured disaster could result. So, I have decided to revert to steel push rods. However, as usual, not that simple as the original rods have different threads in them as, at some point, I changed the rod end specs to left and right hand threads so the suspension height could be adjusted in-situ. So, at the moment I am sourcing 14mm OD thick walled tube as opposed to solid bar so I can keep the weight increase to a minimum and increase the gap between rod and wishbone (carbon tubes are 18mm).  |

| |

Last Edit: Mar 8, 2023 23:19:43 GMT by nalesutol

|

|

|

|

|

|

|

|

Update on Push rods. Got a quote for 1m length of 15.88mm OD seamless steel with a 4.06mm wall thickness - £139 including shipping! Ouch, rethink time. Gone back to an earlier design using 6082T6 grade aluminium. This is the strongest of the 6000 grade alloys, which is particularly suitable for structural applications and also for welding & machining.

|

| |

|

|

mk2cossie

Club Retro Rides Member

Posts: 2,948  Club RR Member Number: 77

Club RR Member Number: 77

|

|

|

|

Update on Push rods. Got a quote for 1m length of 15.88mm OD seamless steel with a 4.06mm wall thickness - £139 including shipping! Ouch, rethink time. Gone back to an earlier design using 6082T6 grade aluminium. This is the strongest of the 6000 grade alloys, which is particularly suitable for structural applications and also for welding & machining. How does the alloy compare price wise to the seemless steel? 😶 |

| |

|

|

|

|

|

|

|

Update on Push rods. Got a quote for 1m length of 15.88mm OD seamless steel with a 4.06mm wall thickness - £139 including shipping! Ouch, rethink time. Gone back to an earlier design using 6082T6 grade aluminium. This is the strongest of the 6000 grade alloys, which is particularly suitable for structural applications and also for welding & machining. How does the alloy compare price wise to the seemless steel? 😶 £12 :-) |

| |

|

|

|

|

|

Mar 11, 2023 13:42:21 GMT

|

|

Finally, decided on size and style of wheels and tyres. Only taken around 10 years 🙂

Nankang AR-1 275/35r15 and 165/50r15 tyres fitted to 9.5 & 6” Image Wheels’ 3 piece billet Ultralites. Form sent to Image for price.

I have gone with 6" fronts so as to avoid any problems with clearance and fouling. There could also be an issue with steering restriction due to the front clam support tubes being hit by the tyres. However, by using 3 piece wheels it is a relatively simple task to increase width by simple replacing the inner rim section.

Need a lie down now :-)

|

| |

Last Edit: Mar 11, 2023 20:51:59 GMT by nalesutol

|

|

|

|

|

Mar 11, 2023 20:14:30 GMT

|

Spent the afternoon in the garage doing little jobs. Started to fit the new hose clamps. Secured some wires. Looked at issue with steering rack. The drivers side boot fouls one of the support tubes for the front clam. I can solve this by raising the rack 6mm by slipping spacers under the rack clamps. Quite a simple fix for a change and it also improves the angle between the rack and wishbones so less adjustment will be required when sorting out bump steer. Don't have any aluminium of this thickness and width so that is ordered. May have to add a little dent into the aluminium rad bottom hose as it is very close to the rack. Also fitted rad cap.      |

| |

Last Edit: Mar 11, 2023 20:18:29 GMT by nalesutol

|

|

|

|

|

Mar 12, 2023 14:02:18 GMT

|

|

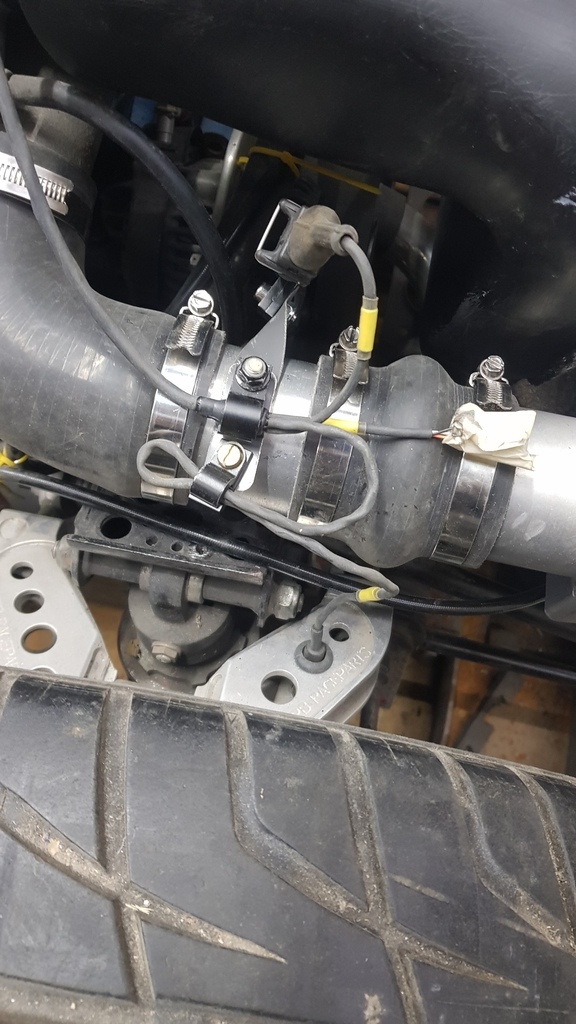

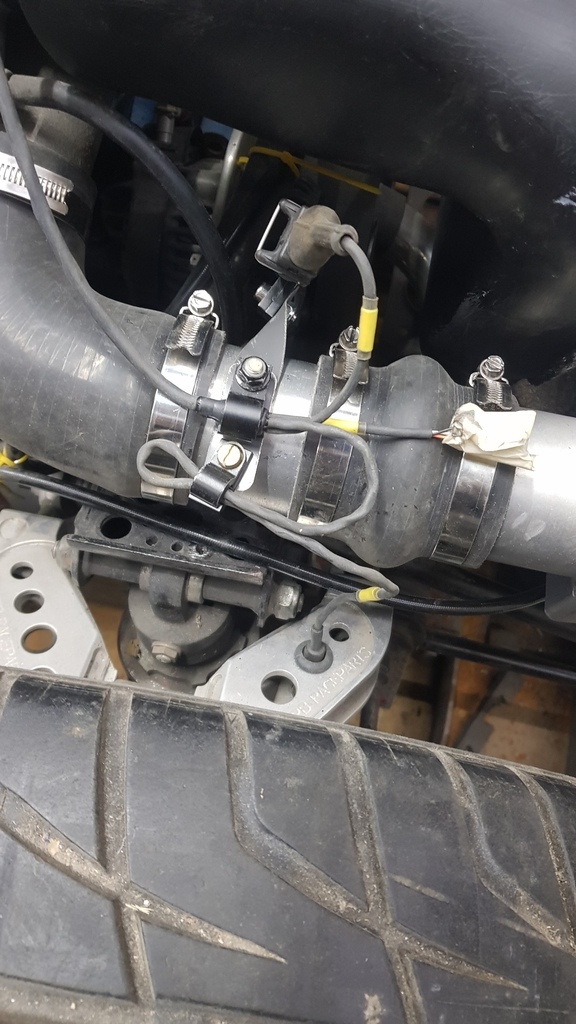

When returning to a project after a few years of relative inactivity you keep finding little surprises. For example, this morning I was continuing to fit hose clamps when I discovered that the throttle body was only held on loosely by two bolts.

That is now rectified but I am going to have to keep both eyes open for any more unfinished jobs. At least I had the foresight to mark nuts and bolts when they had been properly tightened.

|

| |

|

|

|

|

|

Mar 12, 2023 22:00:57 GMT

|

Took most of the day, but finally completed the installation of the water and air hose clamps. When I first fitted the intake hose clamps they were slightly too large so the excess was waving about in the breeze and looked tacky (the next size down was too small) so I took them off and shortened them by around 30mm. Did this to all the hoses. Not only does it look tidier it removes the risk of catching myself on them. As an aside it also removed around 40gms but that is bye the bye :-)   |

| |

Last Edit: Mar 14, 2023 10:26:25 GMT by nalesutol

|

|

|

|

|

|

|

When returning to a project after a few years of relative inactivity you keep finding little surprises. For example, this morning I was continuing to fit hose clamps when I discovered that the throttle body was only held on loosely by two bolts. That is now rectified but I am going to have to keep both eyes open for any more unfinished jobs. At least I had the foresight to mark nuts and bolts when they had been properly tightened. I would be having 100 paint dots on some fasteners since the hobby seems to be how many times do I fit and refit any given part? |

| |

|

|

|

|

|

|

|

When returning to a project after a few years of relative inactivity you keep finding little surprises. For example, this morning I was continuing to fit hose clamps when I discovered that the throttle body was only held on loosely by two bolts. That is now rectified but I am going to have to keep both eyes open for any more unfinished jobs. At least I had the foresight to mark nuts and bolts when they had been properly tightened. I would be having 100 paint dots on some fasteners since the hobby seems to be how many times do I fit and refit any given part? :-) But this is preferable to “I won’t tighten this until I am sure I am not going to take it off again”. Did this around 40 years ago. When fitting twin DCOE Weber’s you have to wrangle the fuel pipes and throttle linkage as they want to occupy the same space. I left the fuel pipe banjo loose so I could adjust it as I fitted the linkage but forgot to tighten it and the obvious happened. Fortunately it went up as I pulled up outside a friend’s house in the middle of a party. People streamed out with beer mugs and washing up bowls full of water (including crockery). By the time the fire brigade turned up we had the fire out, or so we thought. The firemen checked the car over and discovered that it was still alight behind the heater unit. A very lucky escape. They said that they usually arrive at Lotus fires to find only the chassis left so I was very lucky that it happened where it did, otherwise I wouldn’t still be working on the car. |

| |

|

|

|

|

|

Mar 13, 2023 13:34:48 GMT

|

|

When I worked in industry as an assembly line mechanic, it was drilled into us that if you put a nut on a bolt you torqued that nut. Simple safety logic even when it seemed pedantic at the moment.

I would like to say the lesson followed me into retirement, but not entirely, still make a lot of judgement calls when fabing stuff up.

|

| |

|

|