Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

|

Apr 13, 2017 12:48:14 GMT

|

The steel arrived earlier this week so I can get on with the work required to sleeve and seal up the chassis. Very little of the steel is actually for the G15 chassis I am working on at the moment, most of it is for other projects and there is 6m of 1-1/2 16swg for the Strato's works   This little lot is also in leiu of payment for the works on the G15. A few bits of tubes cut roughly to length that will be fully welded into the chassis - the holes that these tubes will sleeve run through all the cross members front to back and carry the alloy cooling tubes. They will be trimmed off to length and then a cooling pipe inserted and placed central in the sleeves and then the sleeves tacked to check they are all aligned before being fully welded.   The G15 chassis is known to flex a little so I set up a test - The steel stip has a bow set in it when clamped and the dial gauge is set to measure how much that bow is taken out when the rear of the chassis is loaded - there was a good 1/4" of bow set in the strip. It was quite surprising watching the gauage whip around as you pressed on the rear upper cross member.   All the bow was taken out and the strip tensioned straight before the front of the chassis lifted ! Now the body itself is a full shell and provides quite a lot of additional stiffness to the assembly when bolted down to chassis - Trouble is that, as mentioned before, the body mounts are not sleeved into the chassis so you cannot bolt the body on rigidly as the chassis tube just gives, so unless you sleeve or improve on the chassis mounts you get less benefit from the body being fixed to the chassis. A simplier "Build a race car kit" than the one sitting outside!  Lots to get on with over Easter - and this time I will make sure I go get a cup of tea at Loton. |

| |

Last Edit: Apr 13, 2017 15:56:28 GMT by Darkspeed

|

|

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

|

Apr 13, 2017 20:57:15 GMT

|

Figured I would do a couple of hours before the Easter weekend starts  Some of the holes are a tad off centre and need to be adjusted - they are also oversized and some weld filling will need to be done.   Tube through for adjusting and getting central.  And then some tacking   A bit of offset welding! :huh:   Six done and two more to go in the morning and then onto the rest |

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

|

Apr 14, 2017 17:59:54 GMT

|

|

|

| |

|

|

|

|

|

Apr 14, 2017 18:31:09 GMT

|

|

A good lot of welds there!

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

|

Apr 15, 2017 12:11:39 GMT

|

A good lot of welds there! Nearly finished - Just made another dozen little brackets and this afternoon will see some nuts welded on. Hopefully my work will be done this later and then Mike the owner can get it back and linish the welds down a little, round off the brackets and get painting. Just popped over to Telford and the gas gauge is back up to 230bar - --  |

| |

Last Edit: Apr 15, 2017 19:05:31 GMT by Darkspeed

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

|

Apr 15, 2017 19:49:49 GMT

|

A few jobs at the front of the chassis today - another crossmember to counter the reaction of the suspension towers trying to twist the chassis rails - Box section is not very good in torsion so it needs to be braced. I will also be adding a better brace to the front of the towers as well. The sleeves welded in a bit better with no huge gap to fill and the ability to place them face up.    I then had to replace a damaged wishbone mounting and add some extra brackets to give the lower wishbone a better support - Mike will have the job of rounding them off to match the others.   Nearly done. |

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

|

Apr 16, 2017 23:02:52 GMT

|

|

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

|

Apr 17, 2017 22:26:29 GMT

|

Final piece of work on the G15 chassis to correct another of the main weaknesses. The G15 uses an Imp crossmemember to attach the Imp trailing arms to, but unlike the Imp where the crossmember is supported by the body shell of the Imp, on the G15 it is sat on top of a piece of 2" box and just its own structure is there to prevent it moving about but move it does. Eventually the crossmember cracks as does the chassis tube. The other issue is that when you really lean on the inside rear the flex in the crossmember can make the wishone go toe out and give some odd handling behaviour. Two things make the damage occur faster - harder springs/shocks and hard driving - a couple of the things that make the G15 corner like a go-cart.   Its not a complete solution as it puts a torsional load into a box section which as we know is not great in torsion but we have a supporting lateral member nearby and its much better than unsupported. Saturday it goes back to its owner and we can return to the odd bit of work on the Stratos, especially seeing as now we have a stock of good steel to add into it. |

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

|

Apr 23, 2017 19:27:19 GMT

|

Not much on the Strato's as I have been finishing the work on the G15 and I have a G21 that I am converting to Mazda running gear for a fellow GOC member taking up space in the garage. Final job on the HRCR G15 is a bit of beefing up of the Imp trailing arms - these are Imp Sport types that are reinforced compared to the standard arms - some over strapping and seam welding should make sure they do not crack in the usual place.   Nearly finished this one. This is where they start to crack - these are good standard arms which have just started to crack    I will reinforce these arms to the same specification as the ones above. |

| |

|

|

logicaluk

Posted a lot

Every days a school day round here

Every days a school day round here

Posts: 1,373

|

|

Apr 23, 2017 20:31:59 GMT

|

|

Mmmmmm welding porn. Dribble

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

|

Apr 24, 2017 19:17:50 GMT

|

Mmmmmm welding porn. Dribble  Even if it is just the grainy amateur version  After that welding mini marathon I am going to treat myself to a really good mask as the cheapy one I was given after my other cheapy gave up the ghost does not make it particulary easy to see what I am doing! Some things may be improved by the light being out and not being to fully see what you are doing but welding is not one of them - although I am sure that plenty imagine they are welding far better than what is presented to them when they open their eyes -  Decision made - Lincoln Viking 3350 - but what Graphics? Motorhead or Mojo In the event that I happen to find a spare £2000 down the back of the sofa - what to do - AC/DC TIG or Coffin Spokes!! I guess I could buy the welder and then prostitute my new found TIG welding skills to pay for the wheels. Then again at least I will have a good motivation to get good at TIG welding. I'll go and throw the dogs off the sofa in a minute and see how my luck is.....  |

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

|

|

|

Motorhead.  More welding this weekend so plenty of oppotunity to find out if a having the best chance of actually seeing what you are doing improves the work. What I do know is that a poor mask or one that's having issues ( autodark type) is an PITA as that happened on Wednesday at G32 Pizza evening whilst making up some seat mounting frames. All was good for the first few welds and then it starting being lazy with reaction to the arc. Having the full arc flash, albiet dimmed a little by the mask shade, in your eye as the weld starts does not leave you much in the way of vision for the first few seconds of welding, if the weld is only ten seconds long that could equal a mess. In the end to complete the job I had to start welding with my eyes closed for a second or so until the mask reacted and I could get on with the rest of the weld. Roland still wishes he could weld as well as I can, even when I can't see what I'm doing!! and does not like the fact that he cannot lay blame on his old Clarke 100E welder - Which actually put down some decent welds when I could see what I was doing. Really loking forward to giving the new mask a work out today. |

| |

|

|

|

|

|

Apr 29, 2017 11:21:54 GMT

|

|

when I made the switch from a crappy hand held mask to an auto-darkening mask, my welding improved no end.

can't recommend getting one enough

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

|

Apr 29, 2017 14:19:21 GMT

|

Well the first welds with the new mask went okay and the mask is a revelation compared to the old one - the view area is huge and the helmet really comfortable and when welding the vision is excellent.  Roland dropped round with the parts we started on Wednesday to have some more brackets welded on so I had the chance to compare the welds with a Hobby welder and a basic autodarkening mask which was having issues and an old Clarke semi pro welder and an excellent mask.  Rolands Clarke 100E and end of life mask  My old welder and the new mask  I now think I need a new torch as it's a bit worn. So next question is can I justify splashing out on an AC/DC Tig set up - I will need to have fuel tanks made and or modified for four cars and have to get cooling pipe junctions made up all which will cost money to have done as well as making up and modifying fuel rails, injector bosses.... I think it would be daft not to. |

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

|

|

|

As it looks like a considerable amount of welding will need to be done using the old MIG I have invested some project funding into a new longer 4m Binzel MB15 torch. I will also strip it down and give it a clean out as that is well overdue. I finished the Imp wishbones on the G15  With the chassis gone and the garage empty I gave it a good sweep out and then filled it full of G21 chassis - Yep Strato's is on hold - The plan devised is to clear all the parts that are making the back of the house look like a breakers yard into the garage and assemble it into a rolling chassis as quickly as possibly.  The G21 is another pretty coupe that Ginetta built after/alongside the G15 - they were sold with the Hunter 1725 GT engine in standard form and the Holbay H120 hot version in the G21S - about 70 were built - Same doors as the G15 and much of the styling was G15 derived almost looks like a G15 was sliced down the middle and made wider and then the rest trimmed to suit.  Running gear was also straight from the Hunter GT / GLS and the usual Ginetta Triumph Herald Spitfire front susupension and steering. Enough of the history lesson. The engine in this one was dead very dead so the owner has enrolled my assistance with getting it rolling with MX5 running gear - I like the MX5 as a donor as the running gear is hard to fault but I was more a fan of just using the engine and box for a quick power plant swap but the end decision was to go IRS as well. So - last week after the clean up  And yesterday  I have also decided to do three projects at once not just the two! - Whilst I do the G21 and the Stratos I will also be building up the powerplant for project 3 my Ginetta G27 so whilst I was down the shed digging out the engine crane I also found and assembled the engine stand. The V8 for the G27 has been a build assisted by the guy I am helping with the G15 that was on the Classic Restoration show stand - I can use glassfibre to an acceptable standard and he knows his way around engines and in particular the Rover V8. He has build and modified more than just a few in his time. The Rover V8 in my G27 was a 20 thou overbored 3.9 - only to 4.0L built by DJE in Nuneaton to a fast road specification - It delivered 232BHP on the rolling road running very rich with a filthy air filter - it was a only on standard valve head with a small amount of porting running a 390 Holley on a very nice medium rise Spider manifold. It was pretty quick - far to quick for the chassis. When I started to assist my mate with the G15 with the GF repairs HE decided that WE would build a better V8 for the G27. To fund this build the majorparts of DJE engine wer sold - I just kept a few key parts for this build. The foundations for this V8 was one of the rarer small journal - leaves a bit more material inside - cross boltable blocks with a standard bore. In his loft space he dug out a set of Group A steel rockers and big shafts and I picked up a pair of very good 4.6 heads and a set of big valves. I say crossboltable as these blocks are not drilled and tapped for the crossbolts - this work has to be carried out on them. To all this we fitted a 4.5 stroked crank and a set of Omega pistons and had the rods shot peened. all the components where matched for weights and lightenend where possible and the entire assembly was dynamically balanced - The group A rockers allow the use of solid lifters so we went for a M248 cam but dialed it back a little with adjustable cam sprocket and duplex chain set. The 4.6 heads were fully gas flowed with the big valves and decided that if going to all this trouble we may as well enable it to breath so its on individual 45mm throttle bodies and will be running semi sequential fueling and ignition via Megasquirt. So - I dug the block out and put it on the stand.    One of the jobs I have to do is weld up and finish the windage tray and also modify the sump to get it to fit.  Cross bolts  ARP fasteners used throughout  Lots of porting work  Duplex springs and steel retainers  So whilst we work on the Stratos chassis and the G21 chassis we will also spend a bit of time assmebling a near 300BHP Rover 4.5 V8 which should be safe to rev to 7250rpm Hmmmmm - there is a bit to do |

| |

Last Edit: May 1, 2017 8:48:25 GMT by Darkspeed

|

|

|

|

|

|

|

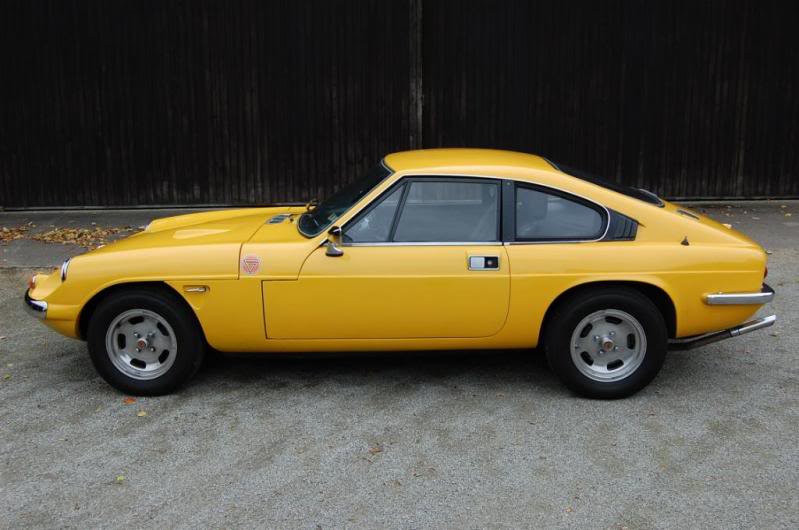

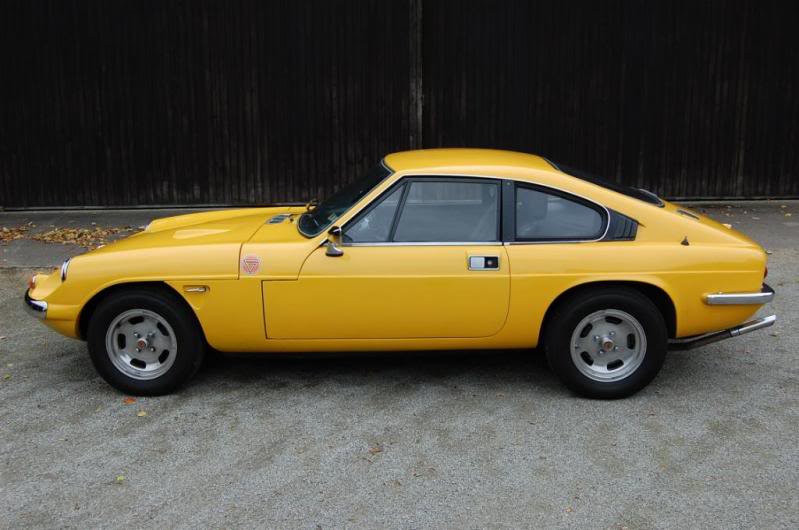

Went to the national kitcar show yesterday, saw this and thought of this thread (there were quite a few, but this one is in the RIGHT colours!)   |

| |

|

|

teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,113

|

|

|

|

I have invested some project funding into a new longer 4m Binzel MB15 torch. I have a Binzel MB15, they are really nice to use. |

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

|

|

|

Spent the Kit Car show time in the garage - when you have seen one Alitalia Strato's you have seen them all  - I probably said before that the rally reps are not for me. I'm going for the same but a little different rather than the same and the same so to speak. teaboy - The old torch is a Binzel TB15 so I figured the latest model should be a fair bet as this one has served well enough. With stealthstylz wondering about the internal of the bug box on the dragster it gave me a little motivation to start tearing down the box from the Grasser The rear casing of the VW transporter box had been modified to take a Hewland MK9 rear casing so the hope was that internally it would yield something interetsing - Especially as well winding the input shaft the ratio's and lack of reverse left me baffled.  One of the shafts had been butchered - this should have had a left hand thread on the end of it - I can only speculate what happened to it because the LH thread had gone and it had been tapped for a cap head and loads of thread lock used to stop it undoing It really did not wnat to undo so drastic action was required.  It's not so bad as the internals are all Hewland  A bit of wear on the dogs on that gear but the dog rings look good and the other gears all look in good order.  Reverse gear idler is there so reverse should have worked  Next I need to get the diff out to look at the LSD. tempted to clean all this up and store it as I am not sure when I will next get the opportunity to own some old Hewland parts, but I should be realistic and get it up for sale to cover these recent spends. |

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,867

Club RR Member Number: 39

|

|

|

|

Did some maintenance on the welder. - New torch fitted and compared to the old one its very.... new.  The biggest improvement is with the shroud and the tip  The old torch was very worn which meant the shroud rattled about on the adapter and the tip is recessed to far due to further wear  The wear meant that I could not use a very narrow shroud as the wear caused the shroud to move very close and with a narrow diameter shroud touch the tip - not good - the new torch should mean far better stability - Money well spent. Just need something to weld ...... |

| |

Last Edit: May 5, 2017 17:37:17 GMT by Darkspeed

|

|

mattiwagon

Part of things

Just got a work truck

Just got a work truck

Posts: 445

|

|

|

|

|

My van?

|

| |

If they cant be nice f**k em!

84 low t25 panel 1.9td beige and rust combo

97 Goped Bigfoot G260RC with clutch conversion

97 Impreza turbo 2000 builders wagon 76k sold

04 Fabia vRs 50mpg pocket rocket

04 battered T5 pickup in blue!

Chainsaws lotsa Chainsaws

|

|

Even if it is just the grainy amateur version

Even if it is just the grainy amateur version