glenanderson

Club Retro Rides Member

Posts: 4,317

Club RR Member Number: 64

|

|

Nov 11, 2021 14:53:37 GMT

|

A "tax in post" note scrawled on a torn off corner of something and wedged in the holder is definitely period, but I'm not sure whether it's a legitimate "dad" mod. I do have a genuine NOS Summit "Magnetax" disc holder if you want one. Happy to donate it to the cause.  |

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

|

|

Nov 11, 2021 15:34:00 GMT

|

|

I've got a very faded suction-cup Garfield if you want him.

|

| |

|

|

|

|

|

Nov 11, 2021 16:20:57 GMT

|

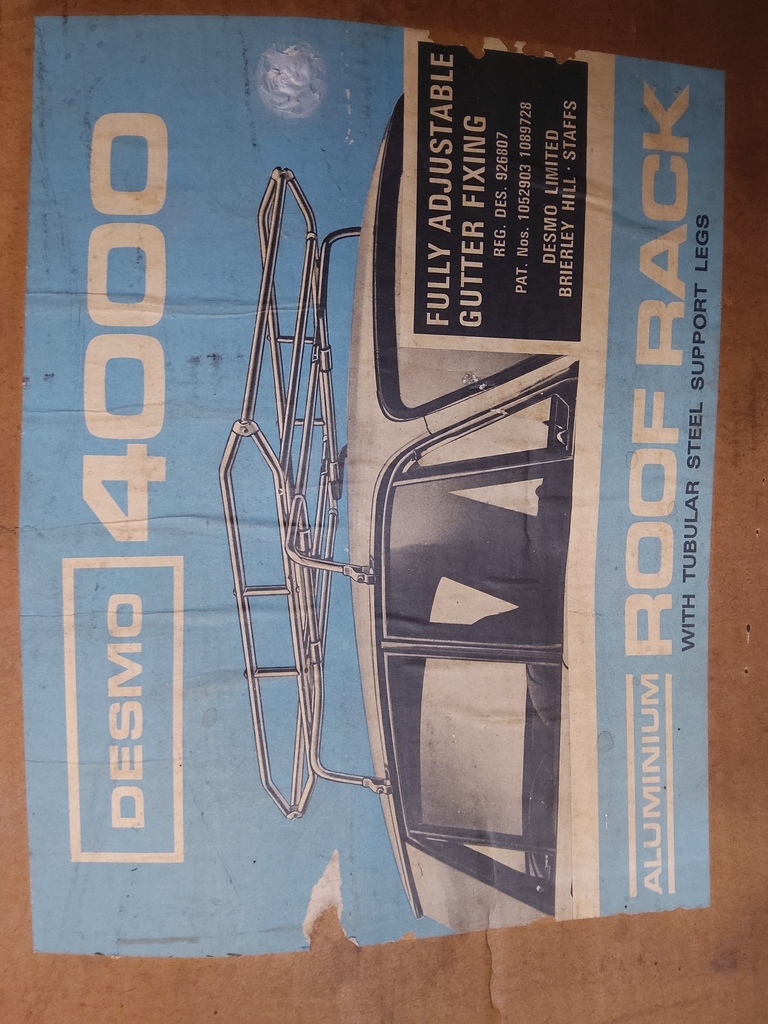

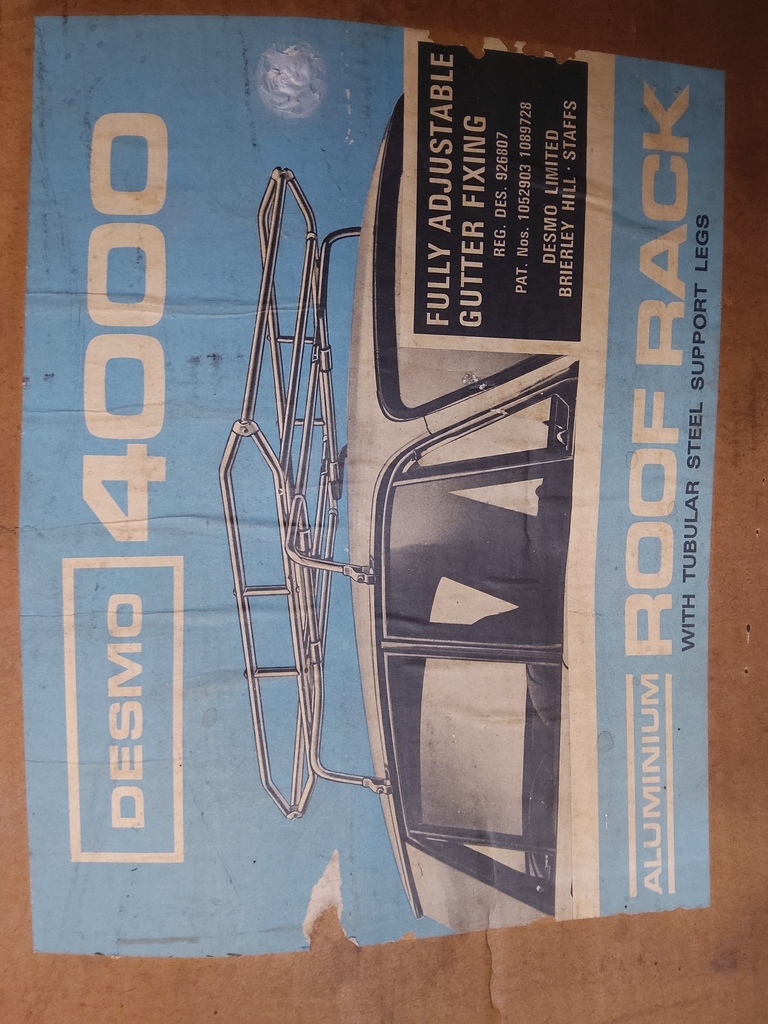

I've got a NOS Desmo roofrack that I got out of my Dads loft last week, any good?   |

| |

|

|

vulgalour

Club Retro Rides Member

Posts: 7,264

Club RR Member Number: 146

|

|

Nov 11, 2021 16:48:41 GMT

|

glenanderson: You know, I could have sworn I had a spare of exactly that type but do you think I can find it? Happy to rehome it. PhilA: Yes! A faded Garfield would be ridiculously appropriate. blackpopracing: No external gutters on the Maestro, sadly... however... the Lanchester used to have a roofrack, you can see the dimples where it was clamped on the gutters and while we weren't planning to fit one if that Desmo unit is looking for a home I can't think of a much better car for it. I can't promise I won't use it as 'temporary' garage storage though. You'll all have to let me know prices, postage, etc. so I can square it all away. Chuck me a PM for all that jazz.

|

| |

|

|

vulgalour

Club Retro Rides Member

Posts: 7,264

Club RR Member Number: 146

|

|

Nov 16, 2021 14:25:18 GMT

|

Everything has gone moderately smoothly with the conversion today. Did my first bit of soldering in years, which went better than expected, made the modifications needed as per the instructions so the wire feed bit lines up properly and then encountered the first of two problems. One problem is that until I have the case all screwed back together, the only-just-long-enough wires that go to the power switch keep pulling out of their clamp. I'll address that eventually, that's just frustrating. The other problem is that the plastic boss that goes around the base of the torch doesn't actually work with my case. The reason being, the boss assumes the front of the welder will be flat and perpendicular to the torch. Mine isn't like that, it has a sloped top half to the front panel so I need some sort of adaptor or filler to make up the space. I don't really have the tools or knowledge to build said spacer. Is it safe to build everything back up without this plastic boss? Is that going to put too much stress on the torch base or am I worrying about nothing here?  |

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,317

Club RR Member Number: 64

|

|

Nov 16, 2021 14:36:19 GMT

|

|

I wouldn't use it without the boss, as the exposed metal parts are likely to be live. I would think it needs support too.

I would have thought a man of your abilities could fashoin a bit of sheet to go straight up the front and fold over to meet the original panel. A bit of CAD and a hunk of sheet chopped out of something lying about. Obviously, it would be easier with the welder working to fabricate it, but chicken-and-egg aside, folding something simple to pop rivet in place would be better than leaving it exposed.

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

vulgalour

Club Retro Rides Member

Posts: 7,264

Club RR Member Number: 146

|

|

Nov 16, 2021 15:58:47 GMT

|

|

I've been thinking more about how to fabricate a spacer for this and I reckon my best bet is probably to get a block of plastic and drill some holes in it before shaping it to the relevant wedge shape. A bend steel spacer is something I can do but there's the issue of metal parts near more metal parts in a location where I feel metal isn't the best solution. Also considered wood, because I've got a lot of that kicking about, I'm just not sure that's a very sensible solution for a welder.

I'm wishing I bought the OEM torch at this point, I'll be honest, would have been a lot easier to fit.

|

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,317

Club RR Member Number: 64

|

|

Nov 16, 2021 16:10:44 GMT

|

|

Wood would be fine.

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

Nov 16, 2021 16:15:50 GMT

|

|

I agree, a bit of hardwood will be fine. Paint it black and it will look factory.

|

| |

|

|

vulgalour

Club Retro Rides Member

Posts: 7,264

Club RR Member Number: 146

|

|

Nov 16, 2021 16:21:03 GMT

|

|

Nearest thing to hardwood I've got is some roof joist offcuts (nobody tidied up in the loft when the central heating was installed decades ago), not sure what wood it is exactly but seems a good bit harder than the fence beams left overs.

|

| |

|

|

|

|

|

Nov 16, 2021 18:22:04 GMT

|

|

Anything solid will do, just not pine or really soft stuff.

|

| |

|

|

penguin45

Part of things

Still welding......

Still welding......

Posts: 70

|

|

Nov 16, 2021 22:56:51 GMT

|

Tax disc holder and maybe a scrap of paper with Tax In Post written on it rather than a repro tax disc Guinness label when I were a lad.... |

| |

|

|

vulgalour

Club Retro Rides Member

Posts: 7,264

Club RR Member Number: 146

|

|

Nov 17, 2021 12:46:45 GMT

|

|

The wood spacer idea is a bust. The central hole that allows the torch to pass through is so close to the fixing holes that the bolts go through that the wood I have just breaks apart when it gets that thin. I would need a much tighter grained hardwood of some sort and probably considerably better woodworking skills to go that route.

Instead, I'm going to pick up a plastic chopping board and use that instead. I've known other folks use them for all sorts of things from budget polybushes to spacers in PCs. Failing that it'll be the bent steel spacer which is likely the easiest thing to make, I'd just rather something not-metal for this if I can do it.

|

| |

|

|

vulgalour

Club Retro Rides Member

Posts: 7,264

Club RR Member Number: 146

|

|

Nov 19, 2021 14:04:56 GMT

|

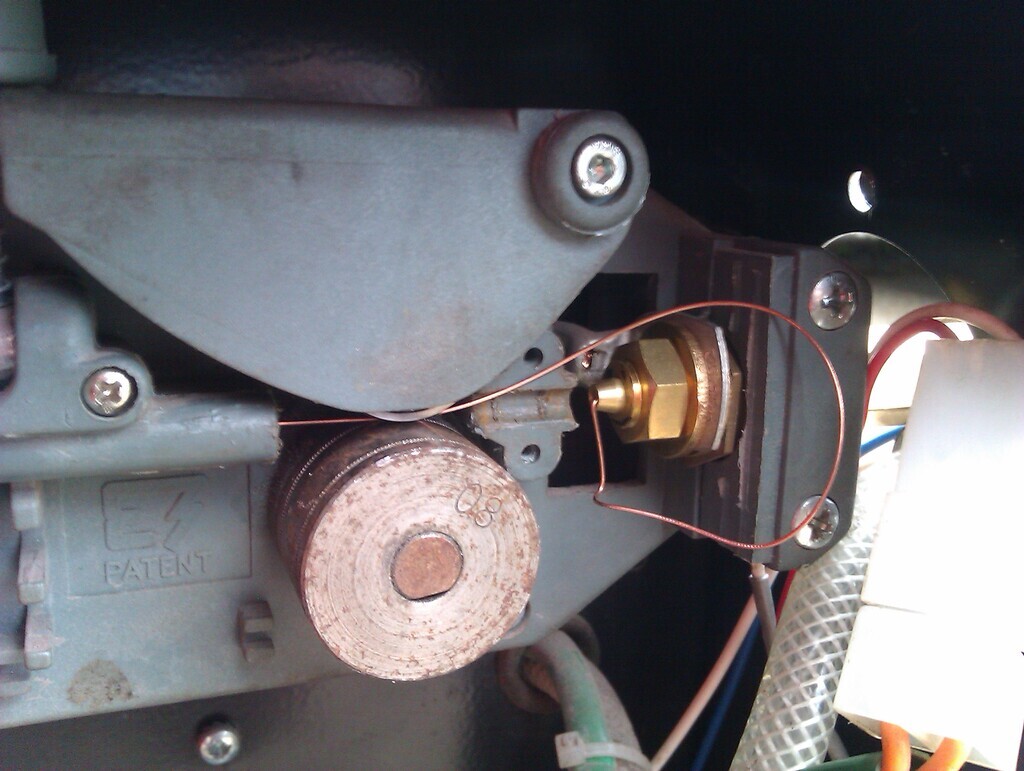

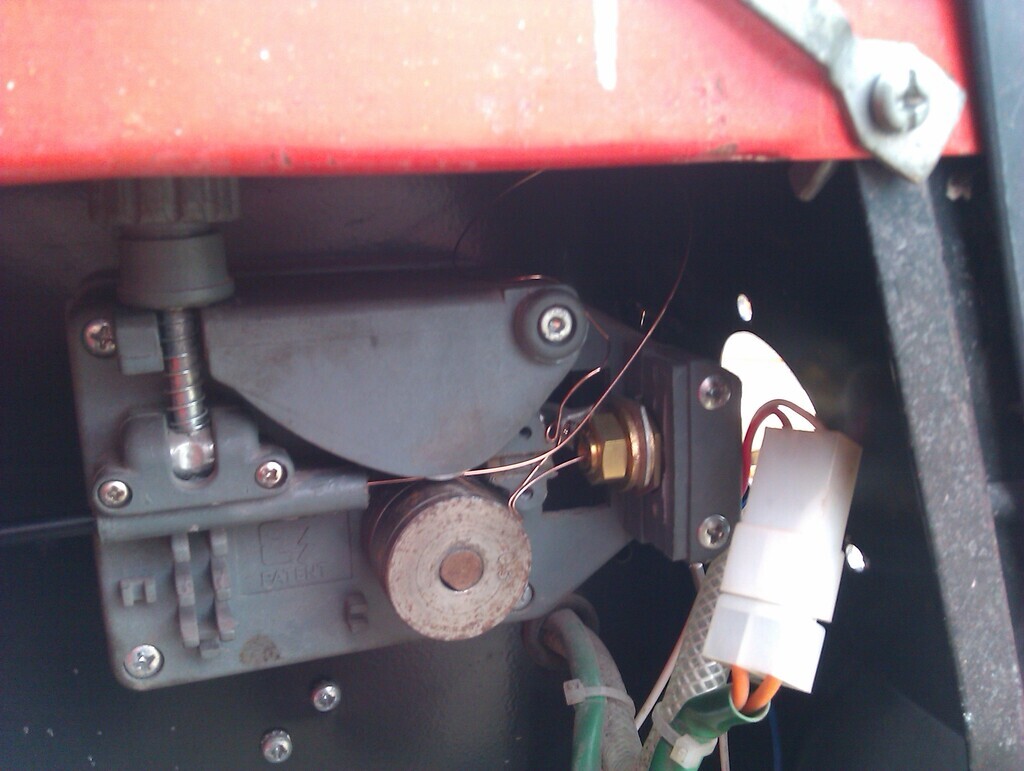

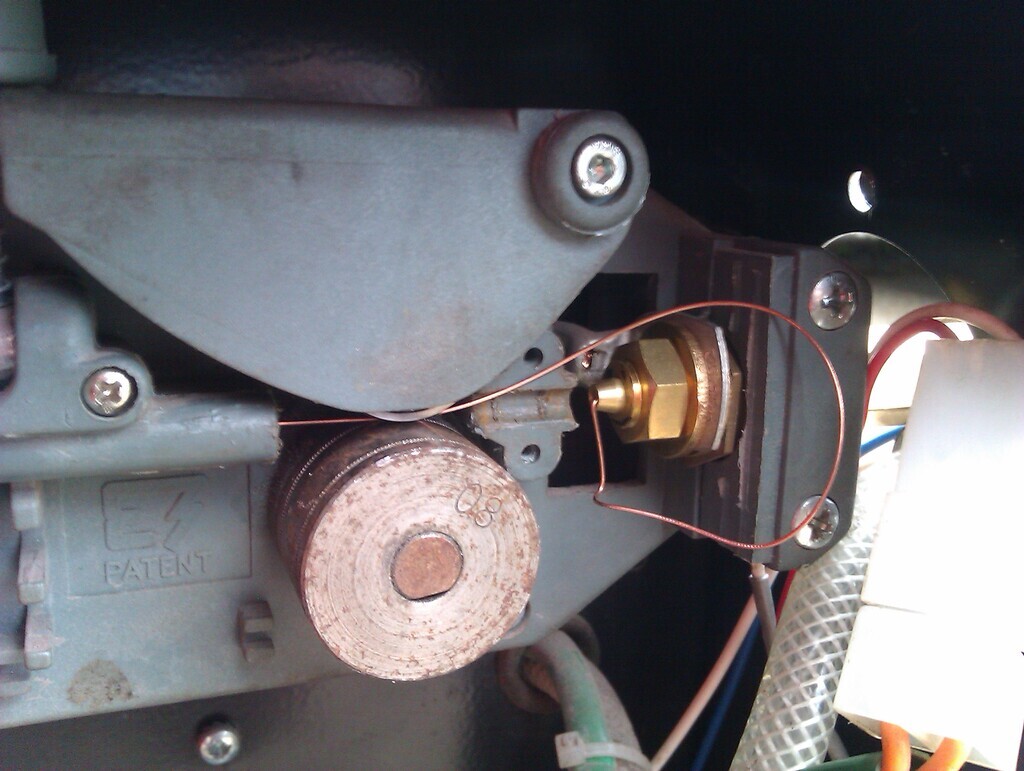

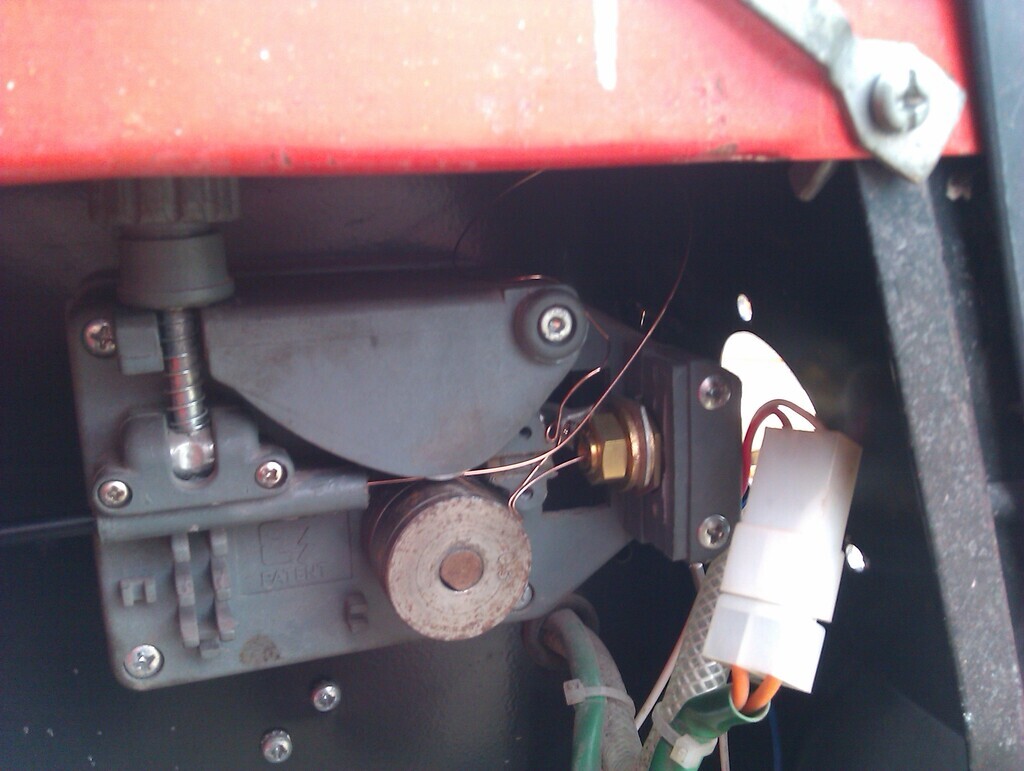

It's not going well.  Reassembled the welder, all nice and as smart as it'll ever be, and decided to test it to make sure it was working. Gas feed is fine, powers up no problem, decided to get some good unkinked wire into the torch to see what happened. It took several attempts to get the wire to feed, I adjusted the tension on the wire reel and the feed rollers until it was as smooth as I could get it and eventually the wire got all the way to the torch tip. Just to be sure, fed some more through and then it snagged as per the above picture. Unthread the wire, check everything is straight so there's nothing impeding the wire, check the screw on part of the torch is aligned properly at the case and attempt to rethread it. Attempt again. And again. Unscrew the torch and find that as the wire comes through the torch boss that's attached to the machine, there's just enough space inside the boss for the wire to then not line up with the torch guide hole. Manually align the wire with both holes, screw the torch back onto the boss, and try again. Wire feeds good, nice and even, let's try striking up on some metal and hope nothing bad happens. Two tacks struck no bother, and then no wire feed at all. Check in the case and find this mess.  Try and clean it all out and find its properly jammed in there. Have to remove the torch to get it all out and find the brass tube that you have to trim down to suit your machine has also come loose (it's held in by bending the tube, there's no other way to fix it in place, as per the instructions). Wire feed is now jerky and I cannot get it to run smoothly.  I don't know what I've done here. I feel like I've wasted a lot of time and some money and I've gone from having a welder that was one of the nicest I've ever used to basically being a new shelf in the garage. I cannot get anything to run smoothly anymore. Perhaps a new wire feed mechanism would help, perhaps getting a new welder (out of budget currently) would be the better solution. I don't know. I need to have a think about this because right now what little confidence I did have doing this job that's out of my comfort zone is now completely gone. |

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,317

Club RR Member Number: 64

|

|

Nov 19, 2021 14:27:18 GMT

|

Oh poo.  |

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

glenanderson

Club Retro Rides Member

Posts: 4,317

Club RR Member Number: 64

|

|

Nov 19, 2021 14:28:32 GMT

|

|

What does the wire look like? - it's not gone rusty on the drum has it?

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

vulgalour

Club Retro Rides Member

Posts: 7,264

Club RR Member Number: 146

|

|

Nov 19, 2021 14:34:51 GMT

|

|

Wire is brand spanking new and lovely and shiny. I've had to waste so much of it just untangling the mess.

|

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,317

Club RR Member Number: 64

|

|

Nov 19, 2021 14:50:57 GMT

|

|

It’s obviously snagging somewhere.

Silly question, but do you have the torch cable out straight from the welder while you’re doing the tests. No tight bends or kinks?

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

vulgalour

Club Retro Rides Member

Posts: 7,264

Club RR Member Number: 146

|

|

Nov 19, 2021 14:51:08 GMT

|

At the moment, my easy fix is this. I didn't realise it could be got on finance (less than ideal) so at least I could get it and get on with the job without worrying about the cost up front. www.machinemart.co.uk/p/mig160tm-welder/It's very close to what my welder currently is, which I liked using before whatever it's doing now, and cost is such that I feel it would be more sensible to get that than chase whatever problem my current one has. |

| |

|

|

vulgalour

Club Retro Rides Member

Posts: 7,264

Club RR Member Number: 146

|

|

Nov 19, 2021 15:00:27 GMT

|

It’s obviously snagging somewhere. Silly question, but do you have the torch cable out straight from the welder while you’re doing the tests. No tight bends or kinks? Yup. Made sure to pull it out straight and that it wasn't twisted in any way. I've had that issue before with other welders and always keep the cable as straight as I can while working. Made no difference. |

| |

|

|