|

|

|

|

|

a chippy who's been dead for 2000 years maybe. I thought he was a shepherd... Unless it was one of those 'kebab and fish & chips' places that mashes two takeaways together  neither offers much experience as an auto electrician mind... I get what you mean about wiring though. At some point there's a really strong urge to just say 'sod it, I'll rip the whole lot out and remake a loom myself'. Haven't yet given in to that urge so can't say whether it just makes things worse!

Well it's all a bit of a fairytale innit. But I'm sure his dad was a Carpenter and he followed in his footsteps until he realise it was the fcuking Messiah. but nonetheless been pretty rank ,at electrics that we can all agree. After spending what seems pretty much better part of week doing the electrics, yeah it probably would have been a lot easier just to rip it all out and start again but that would also take quite a long time to do.

Any how DHL turn up with the goods today. Something even Jesus couldn't have done. not a fish or slice of bread in sight.

Not bad 8 day after doing the bank thing boom it arrives from the other side of the globe. Sexy as fcuk and thats just the box. I did think about doing one of those videos "the unboxing things " but not my thing. Couldn't even bother taking in photographs of what was in it, it was just like Christmas, as a kid, just had to sort out what was really important and get it on the car.  2 hours later it was trial fitted to the car, all working and going up and down the box. Tomorrow be t making sure everything works properly, cutting out and making a decent surround and fitting in in the downshift sensor for the output for the ECU/Dash. Then adding more to the clusterfuck of wiring. |

| |

Last Edit: Mar 8, 2022 22:35:37 GMT by Bullstarz

“It Doesn’t Feel Pity, Or Remorse, Or Fear, And It Absolutely Will Not Stop, Ever, Until You Are Dead!”

|

|

|

|

|

|

|

|

|

|

When you say it was all working going up and down the box it actually drives. I'm a bit surprised that you managed to get all that done and the car drivable in two hours as from the photographs it looks like all the electrics are in bits.

|

| |

|

|

|

|

|

Mar 13, 2022 21:14:21 GMT

|

When you say it was all working going up and down the box it actually drives. I'm a bit surprised that you managed to get all that done and the car drivable in two hours as from the photographs it looks like all the electrics are in bits. No its not driving, the electrics are sill a mess. But the S1 is fully fitted now all torqued down and sealed. Took a while to get a working signal from the gear position sender. But got a voltage that can work with, starts 4.5v in neutral down to 0.5v in 6th, just have got to sort out reverse. With the electrics, I'm looking into sorting them out with a PMU, PDU or PDM. Varying in price and inputs and outputs. I thought the ecu master look quite good and was under £1000 . But you have to invest in a can to USB adapter to be able to programme it. The aim ones, well the PDM 8 isn't really worth having, PDM 32 very good but very expensive. Haltech are bring one out next month, possibly but without a price confirmed and that is 16 outputs but very few inputs. one Ive just looked at again and that is the Hardwire PDM 25 or 15. A UK based company so that's a bonus rather than being Australian. But I haven't heard many reports of people using them, on you tube all looks good. I've looked at their software and it's compatible with my ECU, which is reassuring unlike the Haltech. Also the PDM25+ seems to have more features than the Aim. So it may be the best one to go for. But quite like the idea of reducing all the electrics to a single control point and use a can keyboard to control all the rest of the switches. Whats the general thought on these boxes of pure witchcraft, worth it or not. I'll no-doubt get one, it will be the same thing as the S1 sequential but the electrics although functioning are a real issue. |

| |

Last Edit: Mar 14, 2022 11:27:14 GMT by Bullstarz

“It Doesn’t Feel Pity, Or Remorse, Or Fear, And It Absolutely Will Not Stop, Ever, Until You Are Dead!”

|

|

|

|

|

Mar 14, 2022 23:13:11 GMT

|

|

A while ago I did look into getting one of these and like you said all have got different pros and cons. The hardwire one I'm not sure but not all of them will work off can. I know this was true afew years ago I'm not too sure now. So don't just jump in and buy one only to find out won't do canbus. But your post got me looking into their products as their English, the ozzy's are there for a reason. It will be interesting to find out what you decide and how good the product is.

How's the sequential gearbox going.

|

| |

|

|

|

|

|

Mar 20, 2022 12:27:07 GMT

|

A while ago I did look into getting one of these and like you said all have got different pros and cons. The hardwire one I'm not sure but not all of them will work off can. I know this was true afew years ago I'm not too sure now. So don't just jump in and buy one only to find out won't do canbus. But your post got me looking into their products as their English, the ozzy's are there for a reason. It will be interesting to find out what you decide and how good the product is. How's the sequential gearbox going. The sequential bit for the gearbox is pretty much done . I've got a proximity sensor that will give a signal that I'm changing down. I've had to make a new gearbox around and modify few little bits as, well hopefully that will be all done soon. the new wooden bit have had a bit of veneer put on to make it look a bit nicer and that is outside in the sun trying to get to drive it quicker. Once again ups dropped off another present.  The hard wire PDM 25+ arrived along with the keyboard. So the jobs To Do List has got even longer, while I trying work out all the electrics and the programming. I thought 25 outputs would be enough, but it seems like you need to have a lot more. Its a case of working out which is the most important to have and needs a direct control .Some things like power to radio doesn't really need its own dedicated button on the keyboard or dedicated output, so that will keep its old switch. All this now that Haltech given a date for there module, admittedly it's a lot cheaper and it has only 16 outputs opposed to 25. I think it's only got 8 inputs where this one is got think 16. but price wise I could have bought two and then it would have had 32 outputs which was something to consider , late admittedly. The only reason I sort of went to get this Hardwire PDM and didn't wait until next month for the Haltech was the It wasn't going to be compatible with any other manufacture on release only their own. So they couldn't guarantee it would update to do so, well not for a while anyway. |

| |

Last Edit: Mar 20, 2022 12:29:43 GMT by Bullstarz

“It Doesn’t Feel Pity, Or Remorse, Or Fear, And It Absolutely Will Not Stop, Ever, Until You Are Dead!”

|

|

|

|

|

Mar 22, 2022 23:45:07 GMT

|

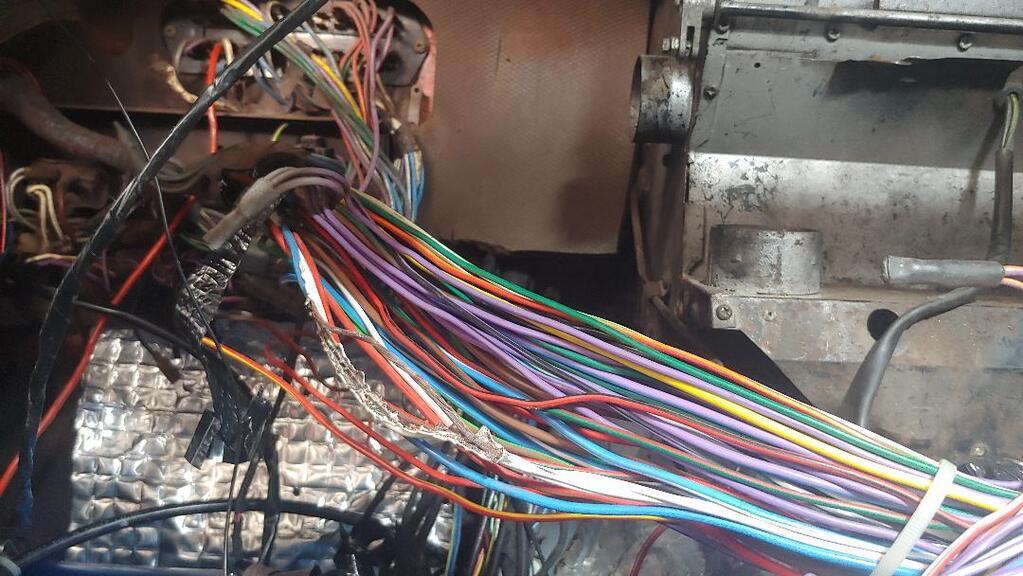

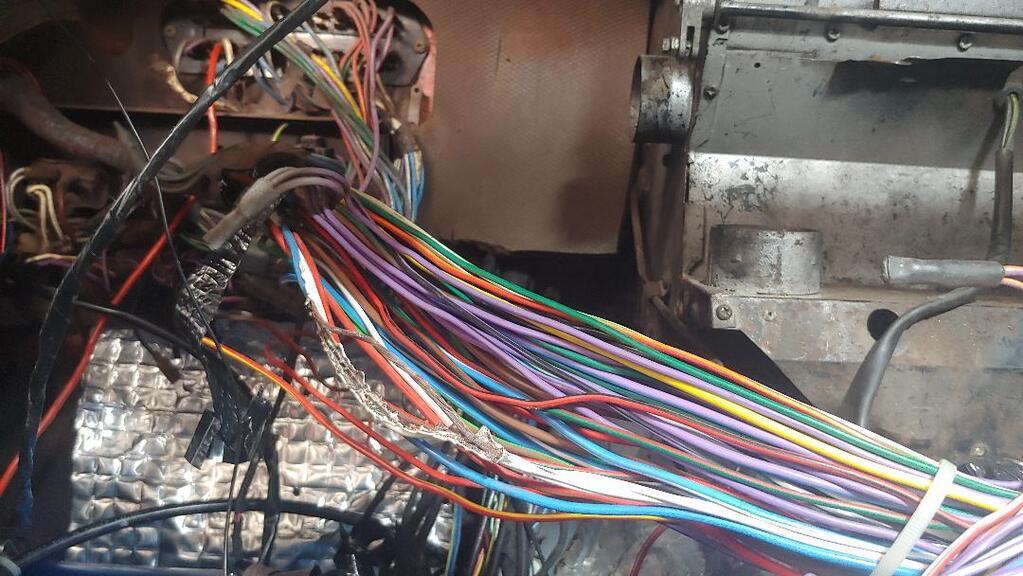

Starting to go a bit deeper into the electrics I didn't like the look of all the old stuff but thought some of it might be usable. Now there all the original legacy stuff that is 50 years old, then there's the bits have been added by every owner prior to me, then all the stuff that I've added on in the last 20 years . First of all I started digging to all stuff Ive added and I know that hardly anything is labelled or marked. But slowly you could see how the more recent stuff over the years has got slightly better, not by a great deal but a small improvement nonetheless. Trying to work out and find what each wire/loom did was quite difficult and meant cutting back the loom tape to get the individual wires. Although I a but of headway there's still a long way to go on it. Then I started looking into the original wiring. I thought its a good stage now to get rid of as much as I could. It did look a bit of a mess so I started start to strip it back so i could delete all the wires it didn't need where it could. Some of them you can't get out because they disappear into the chassis or somewhere you don't know which part is live and which is not. So these were heat shrink.  This is the sort of thing that was hidden. years of continual rubbing against the bulkhead has caused allsorts of issues. The damage could not be seen due to being wrapped in the original loom tape and this particular bit was against the bulkhead so Realistically there was no way I knew that this had happened . Now I'm sure that my stag isn't just a one off, almost all the cars of a similar age realistically need a full rewire just to be safe. Now luckily for me this wire had been put out of use A while ago. But with cars of this age will always find a bit of power or current from somewhere this did just that the wire and get itself stuck to the wires next to it. So where I thought it's going to be sorting out all the wiring for the ecu and PDM the next few weeks will probably just getting rid of all the junk/unused wiring. |

| |

Last Edit: Mar 22, 2022 23:47:43 GMT by Bullstarz

“It Doesn’t Feel Pity, Or Remorse, Or Fear, And It Absolutely Will Not Stop, Ever, Until You Are Dead!”

|

|

|

|

|

|

|

I thought he was a shepherd... Unless it was one of those 'kebab and fish & chips' places that mashes two takeaways together  neither offers much experience as an auto electrician mind... I get what you mean about wiring though. At some point there's a really strong urge to just say 'sod it, I'll rip the whole lot out and remake a loom myself'. Haven't yet given in to that urge so can't say whether it just makes things worse!

Well it's all a bit of a fairytale innit. But I'm sure his dad was a Carpenter and he followed in his footsteps until he realise it was the fcuking Messiah. but nonetheless been pretty rank ,at electrics that we can all agree. After spending what seems pretty much better part of week doing the electrics, yeah it probably would have been a lot easier just to rip it all out and start again but that would also take quite a long time to do.

Any how DHL turn up with the goods today. Something even Jesus couldn't have done. not a fish or slice of bread in sight.

Not bad 8 day after doing the bank thing boom it arrives from the other side of the globe. Sexy as fcuk and thats just the box. I did think about doing one of those videos "the unboxing things " but not my thing. Couldn't even bother taking in photographs of what was in it, it was just like Christmas, as a kid, just had to sort out what was really important and get it on the car.  2 hours later it was trial fitted to the car, all working and going up and down the box. Tomorrow be t making sure everything works properly, cutting out and making a decent surround and fitting in in the downshift sensor for the output for the ECU/Dash. Then adding more to the clusterfuck of wiring. I've obviously missed the post or forgot, what gearbox have you fitted? |

| |

Still learning...still spending...still breaking things!

|

|

|

|

|

|

|

The gearbox in the car is a tremec T56 Magnum. All I've done is to fit this S1 sequential part. Essentially it turns this H pattern gearbox into sort of a pesudo sequential box. There's a whole load of gears, levers, cogs and witchcraft that when you're pulling back on the lever or pushing forwards it mimics the action that was taken as you go through the H box. Is very easy to fit and one of the quickest things have done recently, compared to what I'm doing now with the electrics. Which is a total nightmare. An awful lot of the looms are now trimmed back with the ends sealed up. As I can't remove the whole length of wire as they disappears into the dark recesses of the car like the wings. |

| |

Last Edit: Mar 25, 2022 8:48:09 GMT by Bullstarz

“It Doesn’t Feel Pity, Or Remorse, Or Fear, And It Absolutely Will Not Stop, Ever, Until You Are Dead!”

|

|

|

|

|

|

|

|

Thanks for the explanation as I never knew that there was the possibility to go from the conventional H pattern to sequencial style - sounds like a lovely bit of kit.

Keep on rocking👍

|

| |

Still learning...still spending...still breaking things!

|

|

|

|

|

Apr 11, 2022 23:02:40 GMT

|

bits have been done, and a few undone. I decided that, yes. the electrics needed sorting out. What took me a day to do 10 years ago has took it must be at least two weeks. All I had to do was rearrange the main engine wiring harness but it took forever. Admittedly I had to get rid of a lot of the old shtie over the past 20 years, and all the other stuff that been done by previous owners and triumph themselves. I'd look to a few over installations of good electrical systems and notice that rather than using bands to identify cables they actually got it printed on the cable itself. I thought this was brilliant. So quick delve into find out how you could do this, and it turned out that you can get a Dymo machine that can do it for you. So I got one of these and ordered all the various heat shrinks to go with it. Only need to find the machine I'd ordered second hand off eBay didn't work. Gutted. I did get it to work after about four hours. But all the Gucci parts of it didn't work and not all the characters worked. Try to work around it but it was a pain in the asre. But help stepped in big brother, well really brother. Brother make a industrial sort of Dymo printer that is awesome. Screwfix very good deal so I ended up with a brother version of the Dynamo. www.brother.co.uk/labelling-and-receipts/pt-e550wvpni absolutely brilliant a bit of kit, wasteful maybe. But you can control it from your phone and computer. As Borat would say " Its very nice,". Not making the car getting back on the road any quicker but it allows me to understand what I've done, and what is coming from where and where it needs to go to. Also I thought it be a good idea too alter some parts of the interior trim. I did quite like the look of think it's called quilted diamond. But it's very pricey to buy. So I though I can do that can't be that hard. So I've bought a girlie sewing machine, some foam, some fake leverette and some screw fix no nonsense spray adhesive. What could possibly go wrong. As it happens quite a lot, getting a sewing machine to do what you wanted to do can be quite a test. Now I'm no youngster and threading a needle isn't the easiest thing to do. But when every time you try and do something and something goes wrong and you have to thread the needle, again and again and again, it can be a bit wearing. Not only to mention the needles kept on snapping and I don't know what the technical sewing word for it is but i know it as a bunch of bastartds. the local sewing shop, sort of thing, jumped in and mentioned that as I was a complete novice and hadnt a clue what I was doing. That everything may be fine and give me a few pointers to make things work. they also unloaded of 20 squid for a few needles and threads. however slowly I think I'm making a bit of progress. Now getting the wiring to function correctly and look half decent just takes a lot of time. Labelling each individual wire and loom takes even more time. Now the two don't necessarily go together but my memory condition needs all the help I can get, so pretty much everything has to be documented and labelled. In fact everything is now entered onto a Word document as I do it. |

| |

Last Edit: Apr 12, 2022 9:46:43 GMT by Bullstarz

“It Doesn’t Feel Pity, Or Remorse, Or Fear, And It Absolutely Will Not Stop, Ever, Until You Are Dead!”

|

|

|

|

|

|

|

Apr 17, 2022 22:33:04 GMT

|

|

No Pics. Thought it would be on the road by now summer just around the corner unless you live up North. Be interesting to see how all the systems work together. Can bus is a complicated thing. And the wiring looks a mess. No disrespect but dragging an old electrical system in to the modern realm of canbus isn't a thing of reality. I cant see how it can all work together let alone function. Thats a whole world of optimism or a whole world of pain. But respect if it pays off.........

|

| |

Last Edit: Apr 18, 2022 10:39:06 GMT by Jedimaster

|

|

|

|

|

Apr 21, 2022 22:05:49 GMT

|

I'll get some pictures when it's at a stage where it would do it justice. I spent many hours chopping looms out I'm making new looms up for the new ecu. What I thought would take a day or two is took three weeks solid work. Not really started on the PDM wiring but just preparing everything for it all to link up with the existing stuff. I've got through literally 10s of metres of Braided Cable Sleeving, to start with I bought a kit which had 6, 8, 10 and I think it was 12mm. then I got another three of the kits but I found that I was using majority of the 6 and 8mm. So then I got a load of 3 and 6mm, as in 20 metres worth. Loads of the heat shrink which covers the ends of the braided sleeving. Plus loads of the heat shrink, for the brother printer, to label the wires and looms. The Brother P Touch is printer thing is money well spent, complicated but good. The Dymo was easier to use for a single uncomplicated thing but as some of the keys/functions didnt work i cant make an accurate comparison. But being able to use the laptop or phone to print is a good thing. I have to thank In Car Design, incardesign.store .For all the wiring, consumables and tools all at short notice. Fantastic service and better quality than you'll find on eBay and Amazon. Not knocking Amazon or eBay but I had to order 6 kits of deutsch connectors just to make 2 complete usable kits. Lucky for their free returns policy. What I have learnt from all the different suppliers even though some look identical to others the quality isnt always as stable. Even the same item from the same supplier can change dramatically with each order. Take some of the heat shrink some will shrink easily while other take an age, same with the cable over braiding some will melt before the heat shrink. While others will stay strong. With rewiring a car best advice I can offer is to start fresh. Note down where all the stuff goes to and from but rip all that old sihte out. It quicker in the long run, it takes an age trying to get it all to marry up other wise. Not that its quick making it all new. The ECU is almost done but there seem even more wires than before, rather than less. It started out neater and clearer, but with all the looms its starting to look massive/messy. When I start on the PDM I expect it to be smother and quicker. Even though it has to marry up to the ECU, cars wiring and CANBUS. I'm going to have to recheck all the wiring for the PDM as the last estimate it needed 145m of wiring to make it all work. Which is alot and big order for incardesign.store/. |

| |

Last Edit: Apr 21, 2022 22:22:16 GMT by Bullstarz

“It Doesn’t Feel Pity, Or Remorse, Or Fear, And It Absolutely Will Not Stop, Ever, Until You Are Dead!”

|

|

|

|

|

Apr 23, 2022 23:45:06 GMT

|

|

Well today was mostly taking things to pieces only to put it back on again, realistically if id thought about the problem, I wouldnt of had to take anything off. So I wouldnt have to put it back on again.

I plugged the ecu in for the first time since the new lot of rewiring, just to see what was happening. Admittedly after it did a firmware update thing, things changed quite a bit but that's nothing new. It saw the can keypad and the dash worked as well, but neither of them worked at the same time. Only to find after sometime that the old map on the ecu and the one i loaded up wasn't the same as the Bit rate, it was different. So all the systems were working against each other.

The next was to the gear box stuff, as the car was slowing being put back together. But as usual things weren't working how they did when I put everything together, with the sequential gearbox. The output from the gear position sensor was very stable and gave a different voltage for all six gears and neutral . And the reverse signal was done by using a separate 5 Volt step down, triggered off by the reverse switch. But nothing new as for some reason neutral first and second I couldn't get a clear signal as the voltage with fluctuating.

So I realised the gear position sensor may have moved a little bit and was going from 4.5 volts to 0.5 volts because it is quite close between the two position, to get max voltage coverage and going from 4.5v downwards. The input is 5v but the Gear Position sensor, GPS, works between 0.5-4.5v.

So after taking the centre console out again and removing the transmission tunnel which is a right pain in the Harris. Not to mention removing all the electrics out of the way, which had only just been put in the way. The problem was not always there. I got a good reading on all six gears and Neutral. When the other loom got power things changed again, the ECU couldnt work out the gears.

Just as confusing and a bit surprised, as each gear gave a separate voltage. When reverse was selected the five Volt step down gave 5 volts. The ECU could see 5 volts and so yeah I'm in reverse mate. But when it could see reverse he couldn't recognise neutral first or second.

I'm not gonna lie it wasn't instant, it must have been a couple of hours until I thought to check the output voltage of the five Volt step down. As soon as the reverse was selected it gave 5 volts this was seen by the ECU and voltmeter. But for some mental reason, which possibly even a professor of electro physics couldn't explain, when the gearbox wasnt in reverse the step down was giving off a varying voltage. Even though it had no power.

So there's another case of electrical gremlins deciding to reek havoc and do stuff that was totally against the laws of physics, which is nothing new. The first idea was back feed as theres lot of stuff. What stops back feed, my personal favourite the diode. So I trial fitted that is a diode to see if it worked and it cured the so voltage oscillation.

And it did what legend. just had to put it all back together. A bit gutted, because I did think should I put a diode and resistors in to stop anything going wrong. I did think, well no, because how can a system cause problems when theres no power. So how could it cause issues. But I should have remembered all the past things because I knew it would go wrong.

The next step is to get all of the ecu inputs and outputs connected and checked over and then we can start wiring in the PDM. There's not many wires to connect to get the ecu 100% connected, well that's what I'm telling myself anyway.

I will post some pictures of it, however, for some reason when I did the wooden bits, as in veneer and paint and all that bollcoks. The varnish just went wrong. So new varnish and the same happened. They look like a prune all wrinkled. Its like the veneers don't like varnish or the other way. What starts off as no bubbles, completely smooth. Ends up next morning with more winkles than a grounds for devoice. The ex wife was know as prune face a complete cnut. Having said that I'm quite liking the wrinkles, not the old bicth, fcuk that. I mean the almost textured look of the wood, looks different.

|

| |

Last Edit: Apr 24, 2022 10:33:41 GMT by Bullstarz

“It Doesn’t Feel Pity, Or Remorse, Or Fear, And It Absolutely Will Not Stop, Ever, Until You Are Dead!”

|

|

|

|

|

Apr 25, 2022 22:49:47 GMT

|

|

Looks like you got a lot of teething problems but I'm surprised the can worked. Ive done alot of veneers dashes over the years and the wrinkles are when you put on the varnish on to thick and it cold. the top layer drys and the underside is still wet. Best off to srape it all off and start again.

|

| |

|

|

|

|

|

Sept 11, 2022 22:50:31 GMT

|

Cant believe it been so long since the last update. The PDM is still having issues with the CAN. But it getting better. The wiring is 90% complete, so in my mind 90% of the car in 100% done. All was good but then I found the alternator had given up the will to make power of the electrical variety. Which was not a quick fix, well it still not back together. One of the reason is a new toy, one that hadn't be used in 4 years, and wouldnt run. Turn over yes. Then 14 hours later with new fuel, plugs, oil + filer, which was a bit of a pig. One or two other little replacements repairs and it alive.  It sounds angry, like a bear laughing that it wants to tear your arms and legs off, while still growling. Ive never liked Hayabusa till this one turned up. |

| |

“It Doesn’t Feel Pity, Or Remorse, Or Fear, And It Absolutely Will Not Stop, Ever, Until You Are Dead!”

|

|

stealthstylz

Club Retro Rides Member

Posts: 14,960

Club RR Member Number: 174

|

|

Sept 11, 2022 23:27:14 GMT

|

|

Awesome. They are silly fast, I rode a mates one a couple of times, was alright from a standing start but the most fun was wapping on the throttle at 70-80mph and going warp speed.

|

| |

|

|

|

|

|

Sept 11, 2022 23:59:35 GMT

|

|

I've a zx12 that was quick and was possibly the best handling bike ive had, brakes were good when you got them into your head.

this thing is heavy but the trade off is the 5 little letters.

Turbo

Which gives awesome a run for its money. Its like..... well I've not ridden the thing yet. But i can hear it taunting me from the garage. Saying I'm not man enough to take it out and MOT's, tax, insurance and speed limits are for pussy's .

|

| |

Last Edit: Sept 12, 2022 0:01:21 GMT by Bullstarz

“It Doesn’t Feel Pity, Or Remorse, Or Fear, And It Absolutely Will Not Stop, Ever, Until You Are Dead!”

|

|

|

|

|

Sept 19, 2022 23:38:01 GMT

|

|

Whats with you and Turbos. Like stealthstylz said there studpid fast, without a turbo. But that would be like an uncontrollable missile, a real rouge.

Its like the difference between a bear knuckle fight and a knuckle fight with a bear.

|

| |

|

|

|

|

|

Sept 21, 2022 21:24:43 GMT

|

|

Cus turbo's make the best noise

|

| |

“It Doesn’t Feel Pity, Or Remorse, Or Fear, And It Absolutely Will Not Stop, Ever, Until You Are Dead!”

|

|

|

|

|

|

|

If theres one reason for not making any progress it this  |

| |

“It Doesn’t Feel Pity, Or Remorse, Or Fear, And It Absolutely Will Not Stop, Ever, Until You Are Dead!”

|

|

|

|

neither offers much experience as an auto electrician mind...

neither offers much experience as an auto electrician mind...