|

|

|

|

|

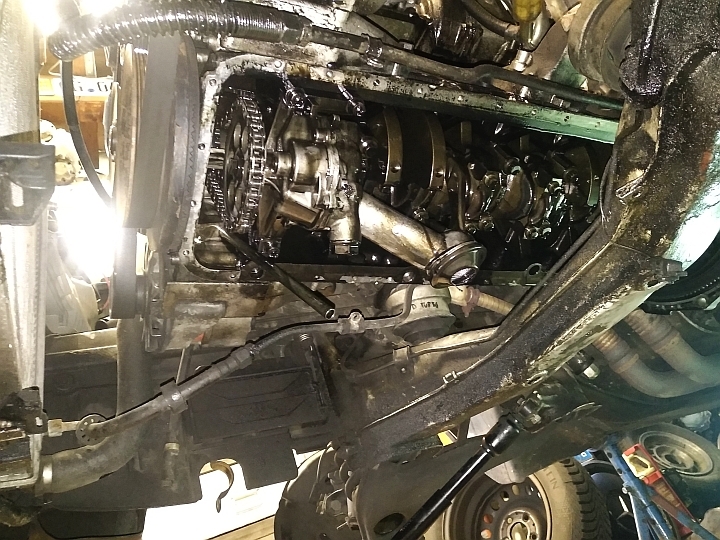

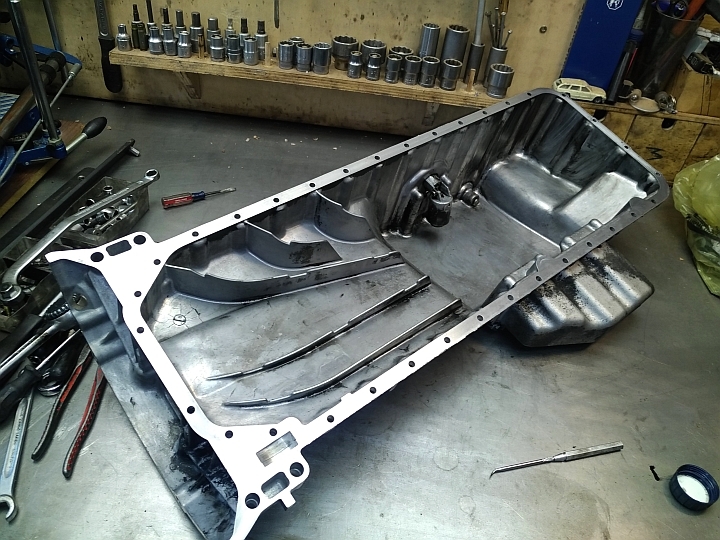

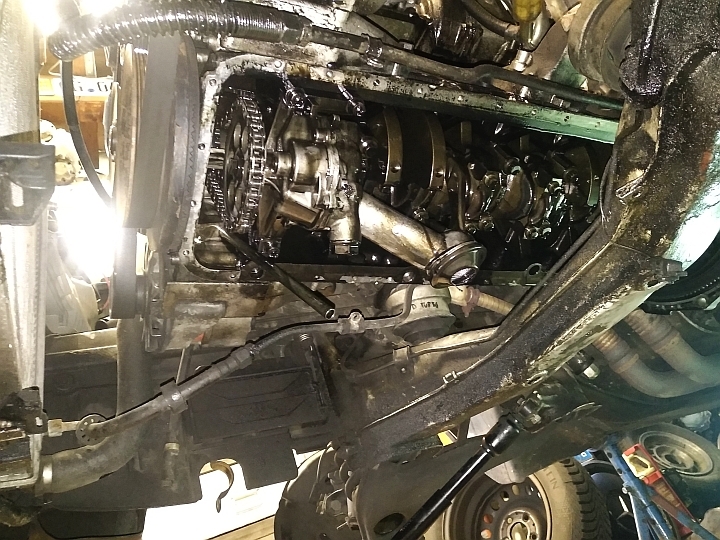

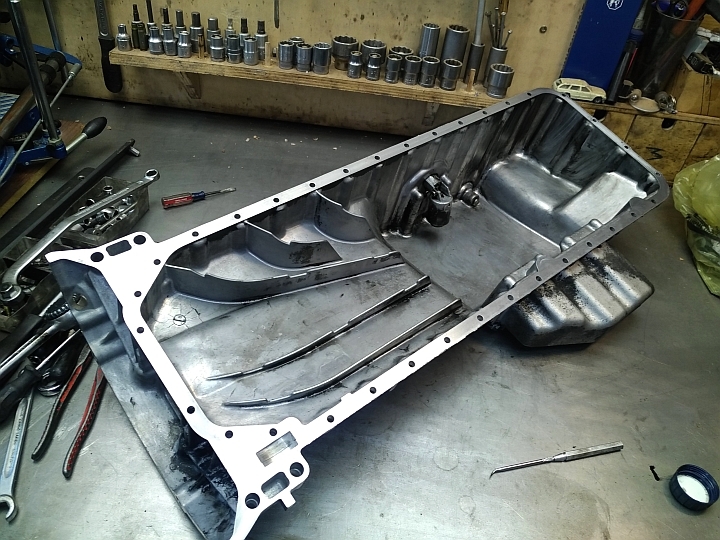

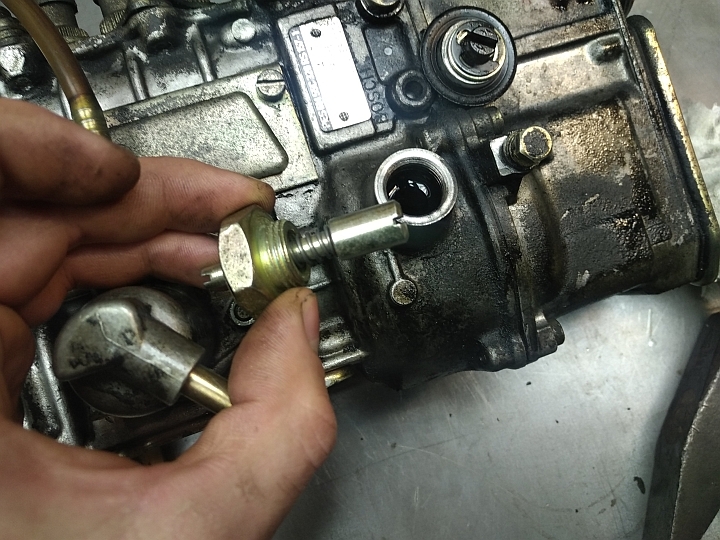

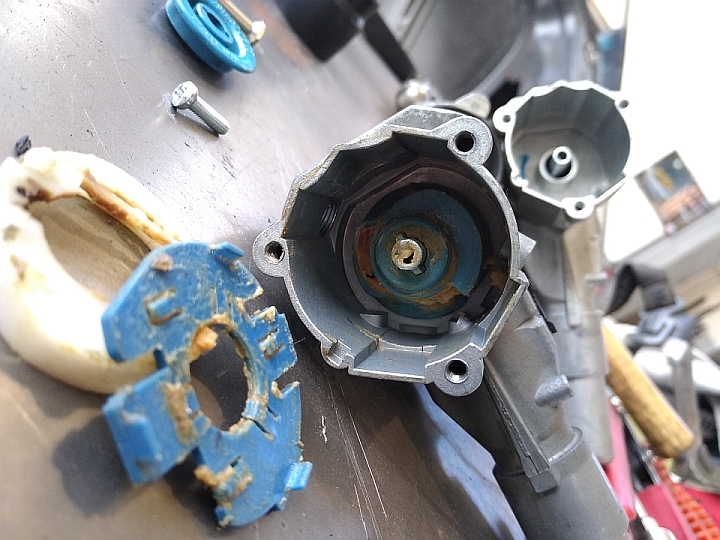

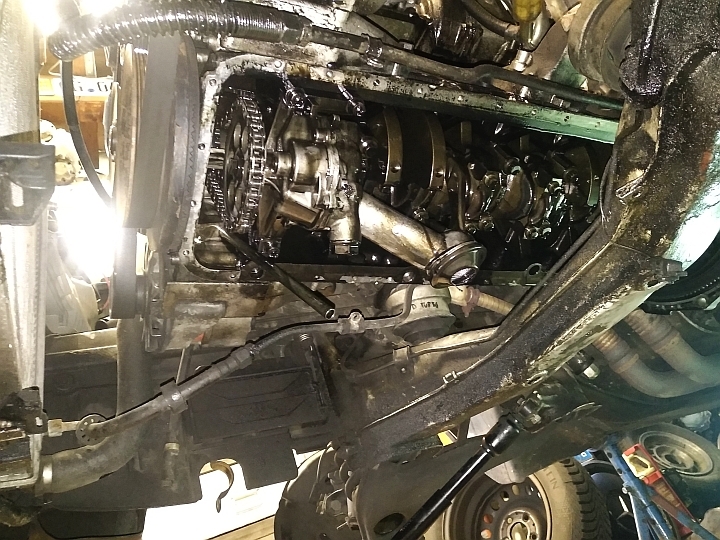

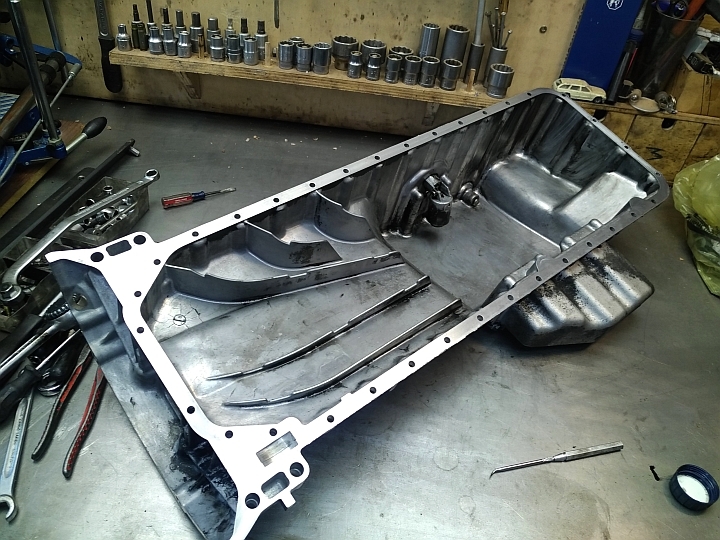

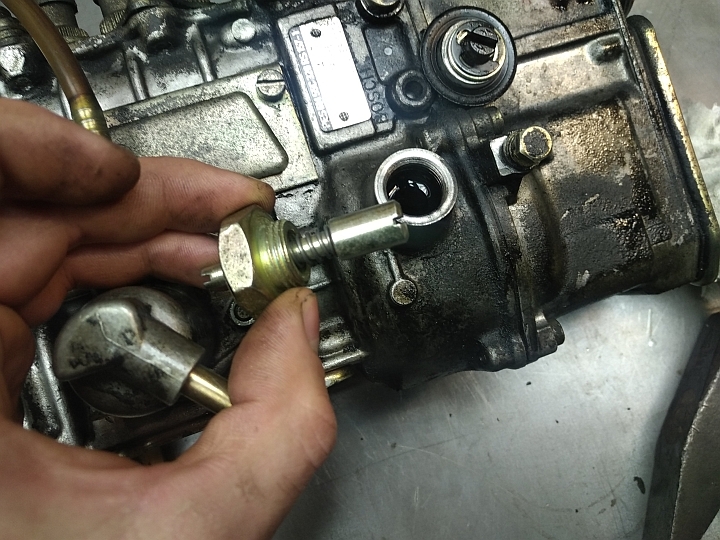

So, It's been a while since I did some major surgery on this... I was never comfortable with the JB Welded oil pan, it as only ever going to be temporary fix. And it started to leak again... I had my doubts that the oil pan would come out. But, I tried anyway. I raised the front of the engine until the oil filter housing mashed the firewall.  All I got was about two fingers more between the crossmember & oil pan. And that was all it needed. I had to remove the center steering link & damper, the hoses runing to the transmission cooler - and it slid right out. With ease actually! Woohoo!  Upon closer inspection, I found that the cylinders are sleeved. And there are punch marks on the bearing caps and block. I can't say for sure, but I think there's a possibility that this engine actually had a rebuild...  I proceeded the install the new pan - which went in just as easy. Since I only had a Turbo oil pan at hand I used it. Which increased the oil capacity from 7.5 to 8.5l.   Next task was to remove the injection pump. To replace the o-ring sealing it to the engine block. And the seal of the bottom pump cover. The latter was leaking really BAD.   And not surprising, the rubber seal was brittle as a biscuit...  Come reinstallation of the pump, I had a bit of a nightmare to get the timing right... It always jumped out of alignment, putting the timing far beyond anything reasonable. But 4th or 5th try I got it right. Barstard!  Took a bit of cranking to get it going again, but it runs well. Phew. And to prevent future oil pan misshaps, I reinstalled the blöödy heavy bit of steel that is the factory sump guard.  Glad that is over. And so far no leaks. Milegae: 1.084.000 Cheers, Jan |

| |

|

|

|

|

|

|

|

Mar 10, 2019 15:43:54 GMT

|

|

I love my Factory steel sump guard, I need another one for my TE.

|

| |

5x112 Highline Bora (in a coma), C124 2.2 (Hibernating), S210 OM606 (Daily)

|

|

|

|

|

Mar 10, 2019 16:54:12 GMT

|

|

fantastic job...quite a bit of wrenching on that for sure!....I just finished the oil pan gasket on my e91.....Had the gasket hanging on the wall for months!

JP

|

| |

I know its spelled Norman Luxury Yacht, but its pronounced Throat Wobbler Mangrove!

|

|

rr69h

Part of things

Posts: 313

|

|

|

|

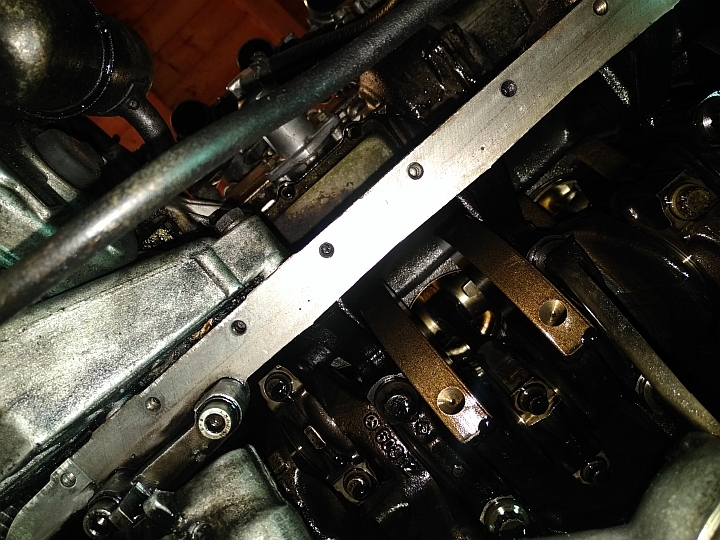

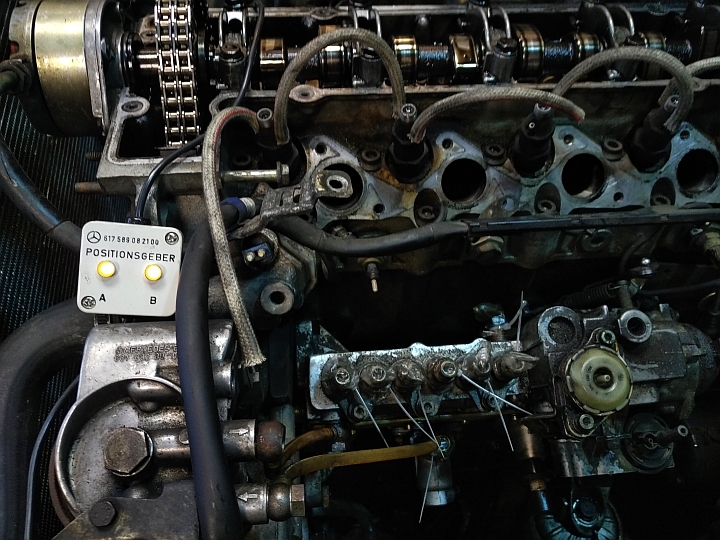

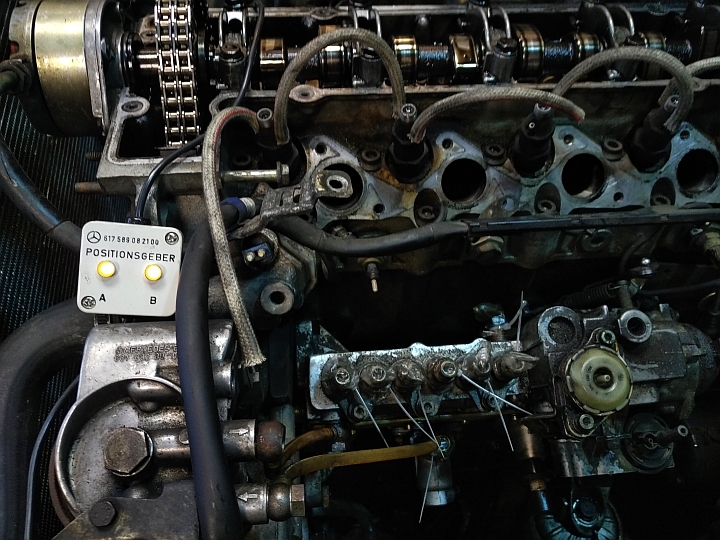

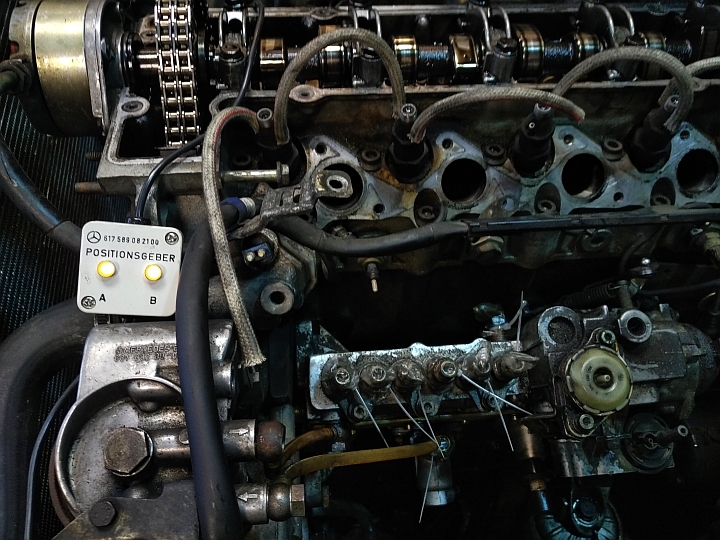

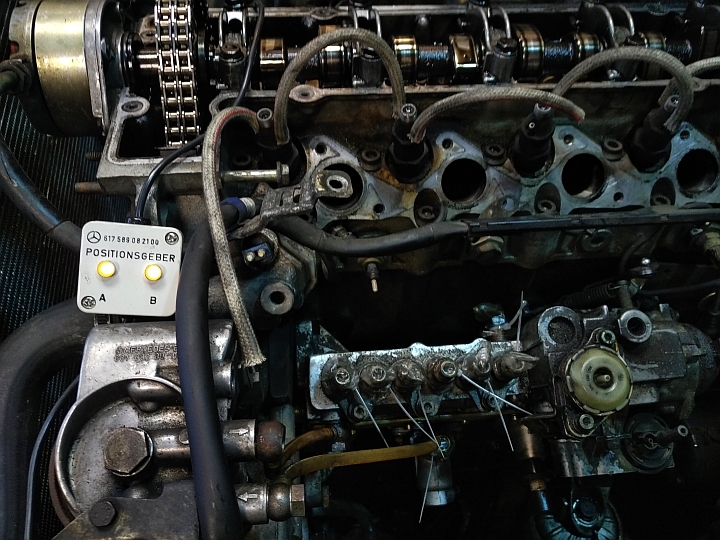

Very nice operation, my good Sir!  If you don't mind me asking: what does that POSITIONSGEBER do?  May this be a device to check the timing of the injection pump? I'm just asking because you seem to be very comfortable yanking the pump out... a job I do not speak about in the most pleasant tongue...  Felix |

| |

"Racing drivers never carry cash"

|

|

|

|

|

Mar 11, 2019 18:02:26 GMT

|

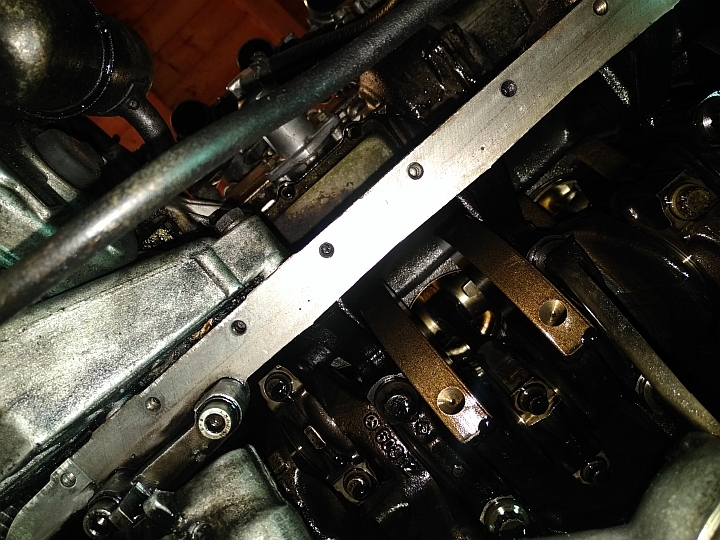

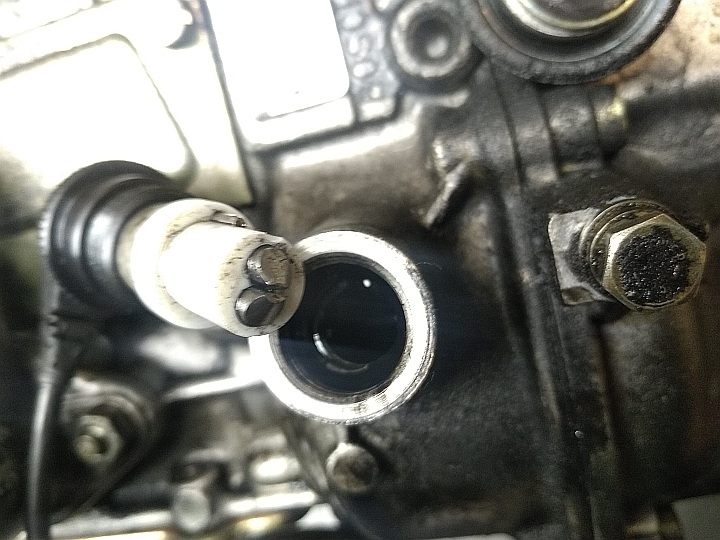

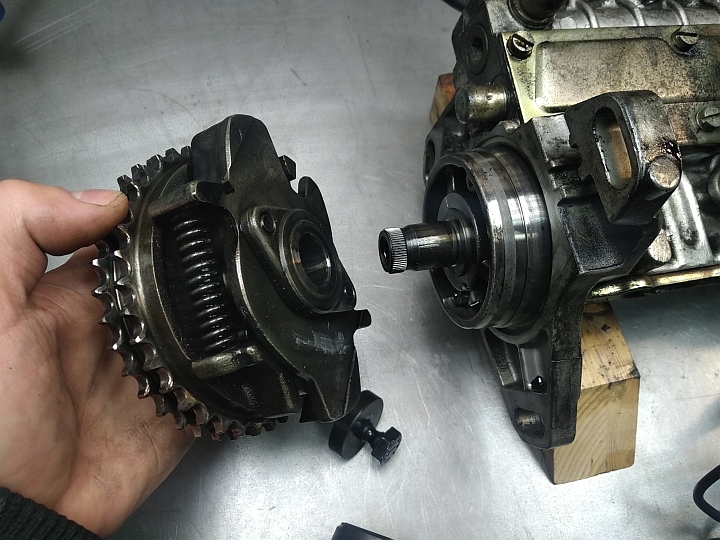

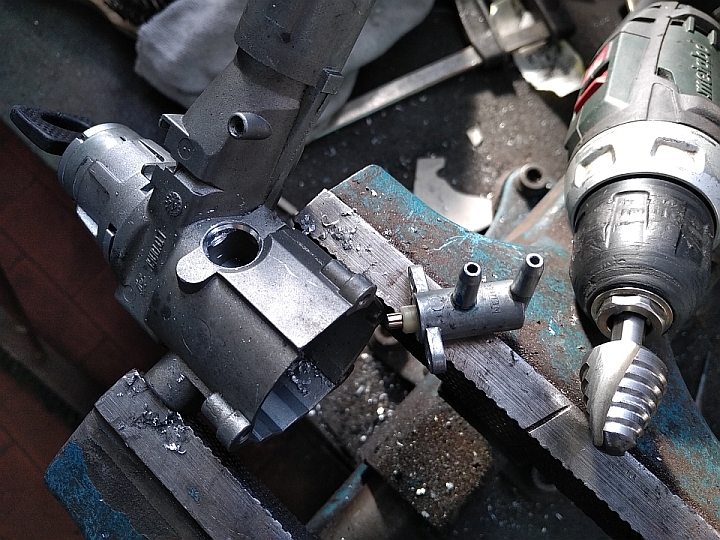

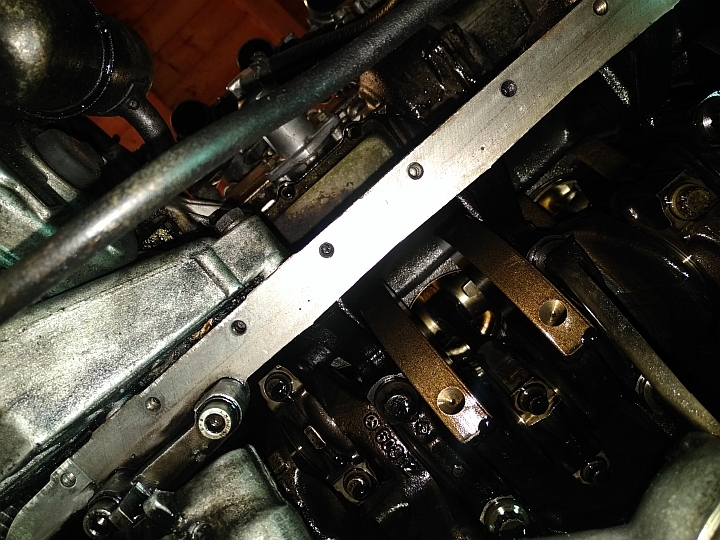

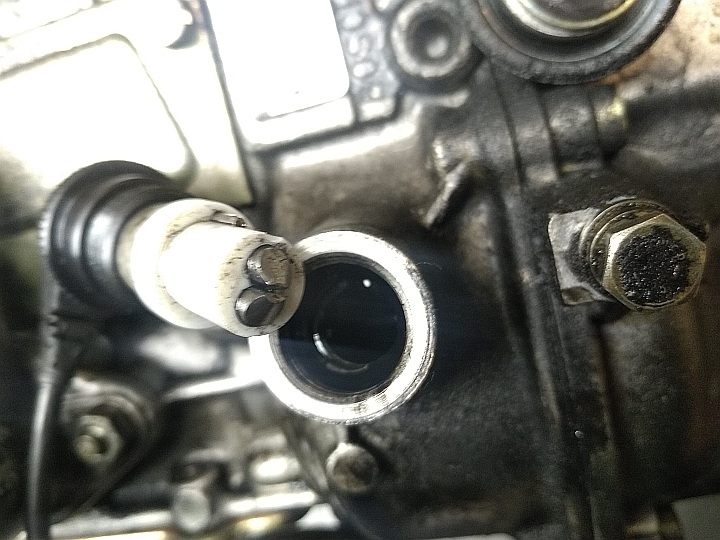

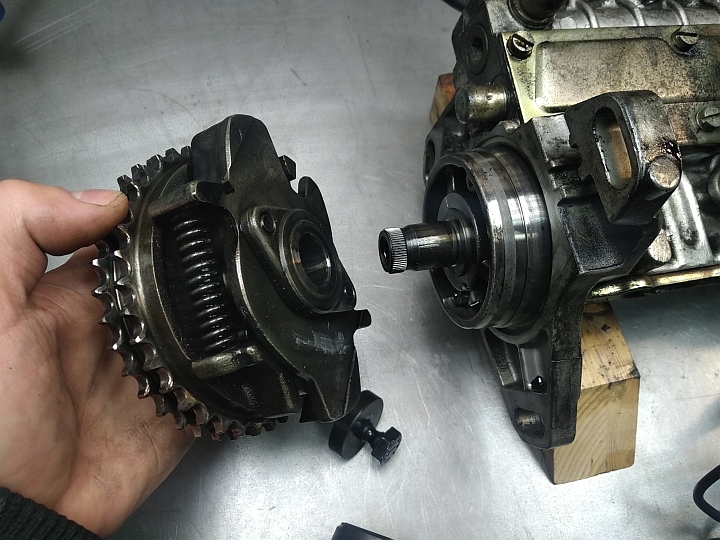

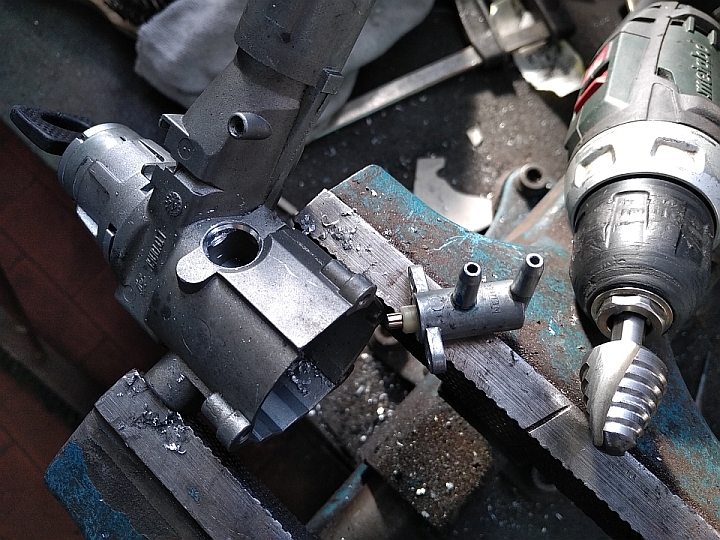

Hi! Yes, it's basically a - static - injection timing tool. There's a little prong on the pump governor which indicates the pump's Top Dead Center, or it's Bottom Dead Center more likely - let's cal it it's "0" timing. It's accessible by a plug:  To time the pump resp. the injection, you simply put the crank on n°1 cylinder Top Dead Center and then rotate the crank further to the desired degree of injection timing. The Injection Timing times the START of the pumping process, so it is measured in degrees AFTER Top Dead Center. Because it needs a good amount of (crank) rotation to build up pressure and inject the fuel. So basically, you rotate the crank to the desired degree after TDC, put the pump on "0" and slide it in. Factory timing is 15° aftTDC. To lock the pump at it's 0, there's a tool which uses the same prong to lock it:  Once the pump is in place (it simply slides into the regulator which is held by the timing chain), you remove the locking tool and install the magnetic sensor of the Positionsgeber. Which has two narrow pickups and reads on the very same prong:  So with the crank at 15° after TDC and the pump at it's own 0 - you now have dialed it in. Possibly. It can be exhausting, since the locking tool doesn't grip the timing prong very well. And it's just in a position at which the springs of the pump elements try to push the injection pump for- or backwards. If it does, the timing is all over the place. Which means - pump out again, check crank timing, re-install locking tool and try again. The regulator itself is basically the link between the timing chain & injection pump. It's the pumps drive and at the same time functions as advancing unit. Same principle as a distributor on a petrol engine - centrifugal advance. It's position on the Injection Pump's input shaft is irrelevant, as long as the crank is at the desired timing and the pump at "0". Remember this.  With the pump installed, you tighten the regulator down (left hand threaded bolt!) and then check the timing with the Positionsgeber - and if neccesary (very likely) adjust it. Since there is no "fixed" position of the regulator relative to the pump. It can be necessary to remove the pump again and rotate it a couple of teeth inside the regulator. Since the adjuster on the pump only allows for a couple of degree of (fine) adjustment. It's not a difficult task with those two tools. It's all very simple and straight forward. But it can be a bit of a pain in the rearend to get the timing right... And the reading of the timing light is VERY fine, I guess it's within a couple of minutes of angle. To get both lights to light up - which is the EXACT static injection timing you need to rotate the crank VEERY gently and slow - it usually takes me at least 3 tries (resp. 6 full rotations of the crankshaft - blargh!). Not hard with the right tools, but it can be exhausting. So I actually do feel comfortable to pull the pump, but I don't like it. Sometimes you get it spot-on first try, sometimes - like this time - it's exhausting repetitive work... I hope my writing & explaining made at least a bit of sense, I'm not very good at explaining technical things......  This timing light was introduced I think around the mid- t late 1970's, I think on earlyer engines you need to proceed with the dripping method. I've not done this yet, but it sounds pretty frustrating... Cheers, Jan |

| |

|

|

|

|

|

May 13, 2019 21:56:34 GMT

|

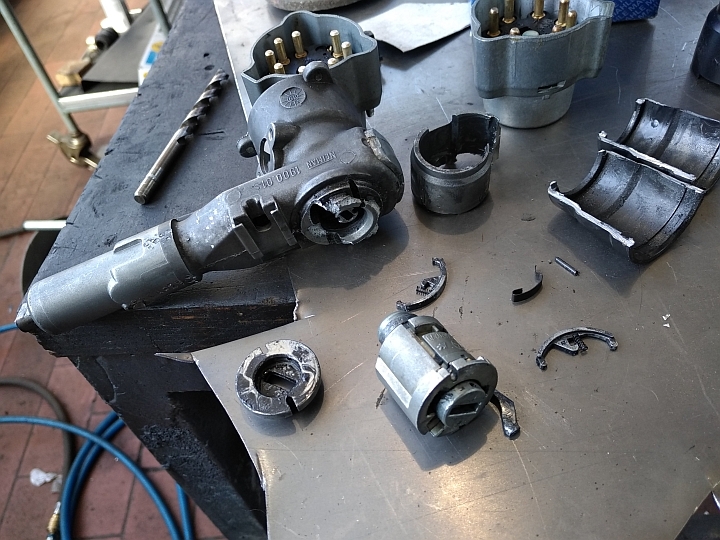

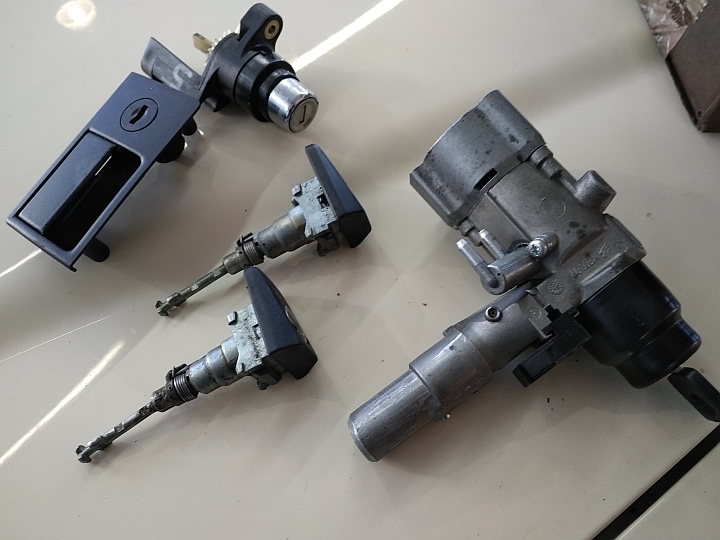

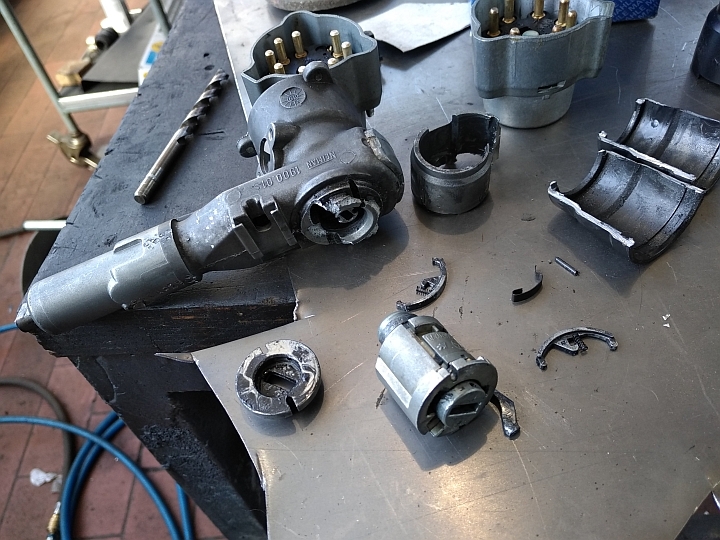

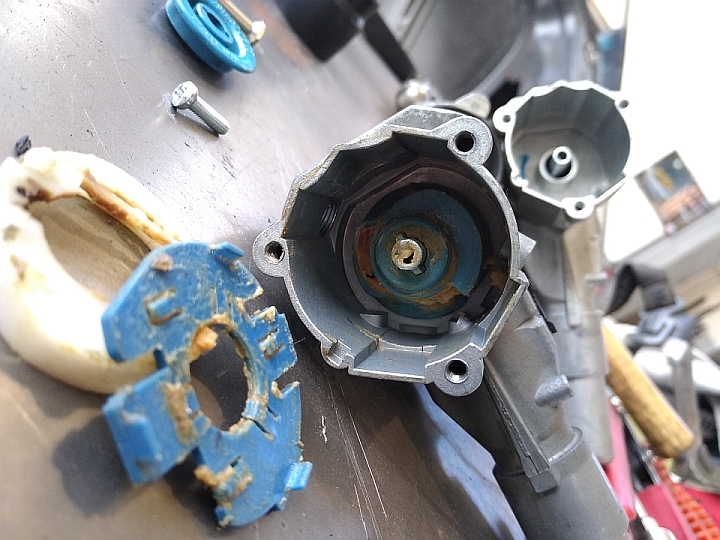

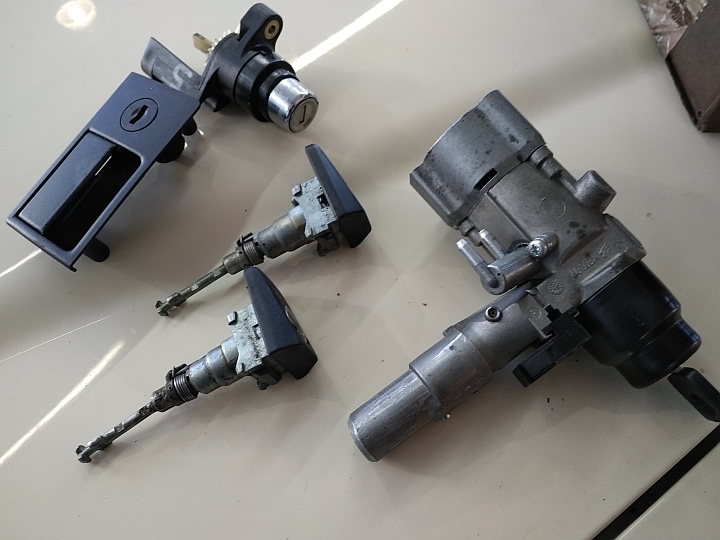

+++NEWS+++ Something major broke. Something that would probably would have required road assistance. Luckily, it happened right when I had the car inside the workshop for a little service. And it was quite surprising, as it had worked absolutely flawless. And stopped working right after I lubed it. WTF!?!?  This was required to get the little curse word out...  The ignition tumbler/lock had seized up. And since we didn't have a diesel steering lock in our collection of spare parts, I drove the car for a couple of days without. Hooked up the starter switch and cable tied it to the steering column. Got a lot of funny looks when I unlocked a runing car with the key, threw the key on the dashboard and drove off...  Anyway, today I took the time to fix this. I took a non-diesel steering lock and converted it. The only difference is a cam that activates the vacuume switch to kill the engine - and three holes.  ^this is out of a Series 2 automatic, when the added the shift lock. With the shift lock automatically comes the diesel shut-off cam. I removed the shift lock (plastic stuff in front) and left the shut-off cam in place, as pictured. Now all that's left is to drill & tap and bolt on the valve.   I took the opportunity to install a lock/tumbler out of a whole set of locks, to prevent having to use two keys to operate the car...  Which finally gave me a reason to replace the passenger's door lock, to which I never had a key the fits. Still need to replace the rear lock in the hatch. Oh, and currently there's a different wing installed:  Because the original needs a bit of attention......  It's been in primer for two weeks, I just didn't get to paint it. Sigh. Anyway, that's all for now. Milage: 1.094.000 Cheers, Jan |

| |

|

|

|

|

|

May 13, 2019 23:06:43 GMT

|

|

I love how you just keep this thing going. My wife thinks her car has high mileage at only 440,000 km.

|

| |

|

|

|

|

|

|

|

|

I also leave my car running while I use the key for the boot, etc. The barrel is that worn that the key just comes straight out, haha

|

| |

|

|

|

|

|

|

|

Funnily enough, I had my ignition tumbler fail in the exact same circumstance as you, after spraying a bit of lube in it. The key difference is that I refused to accept I'd have to take it out the way you've had to, so instead spent at least an hour messing with the key to get it to turn over, with success! The more I used it, the better it worked as well, and I've since been confident (aka irresponsible) enough to continue using said tumbler without a hint of worry. Cheers  |

| |

1991 Mercedes-Benz 300D Turbo † ~~ Met a cute daydreaming DS3, it was love at first sight... 1993 Mercedes-Benz 300D Turbo ~~ Current daily [Thread] |

|

|

|

|

|

|

|

Ran my Wolseley with screwdriver start for years cos the key switch was broken. Driver's door doesn't lock either. If I had to leave it somewhere a bit dodgy like in the airport carpark I just took the dizzy rotor out.

|

| |

|

|

|

|

village

Part of things

Always carries a toolbox. Because Volkswagen.......

Always carries a toolbox. Because Volkswagen.......

Posts: 567

|

|

|

|

|

My Mk1 Golf Diesel would let me remove the key with the engine running. I used this on cold days when I returned to our work yard, where I started the car up, set the heating to a middle temperature and the fan on low speed on the windscreen, put the crooklock on, relocked the car and went off to unload/load the work van for the following day. 10-15 minutes later, the car was defrosted and warm, ready for the journey (and inevitable thrashing) home.

|

| |

Last Edit: Aug 22, 2019 7:41:08 GMT by village

"The White Van is strong with this one...."

Chris "Chesney" Allen 1976-2005 RIP

|

|

|

|

|

Aug 21, 2019 20:12:21 GMT

|

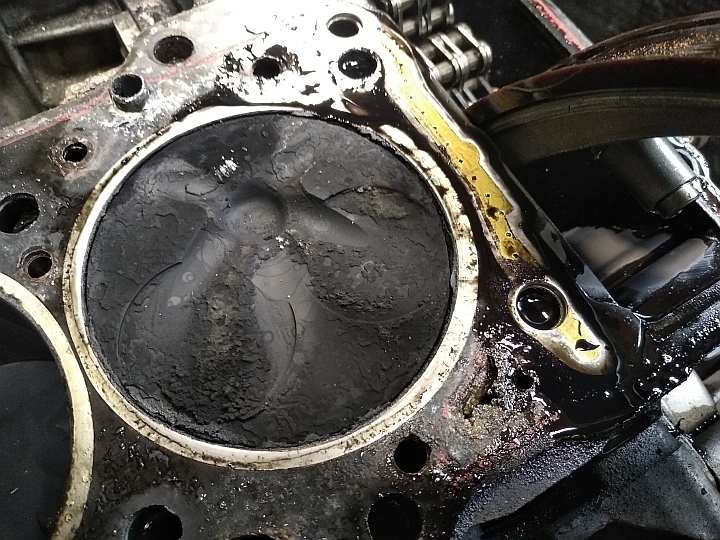

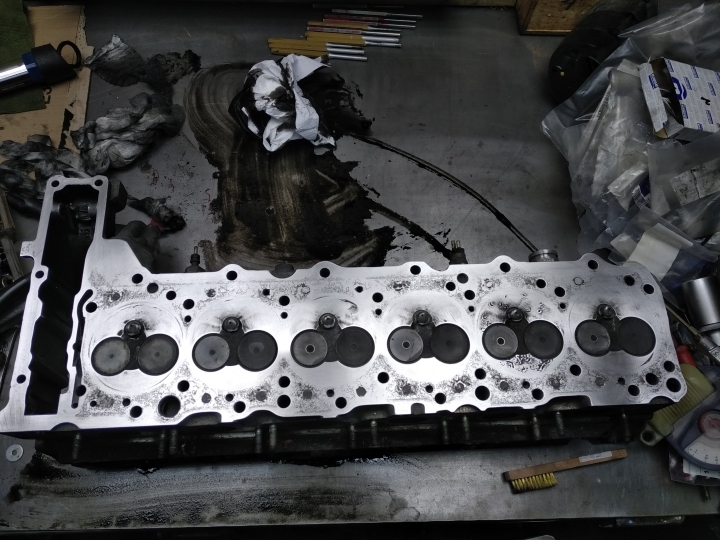

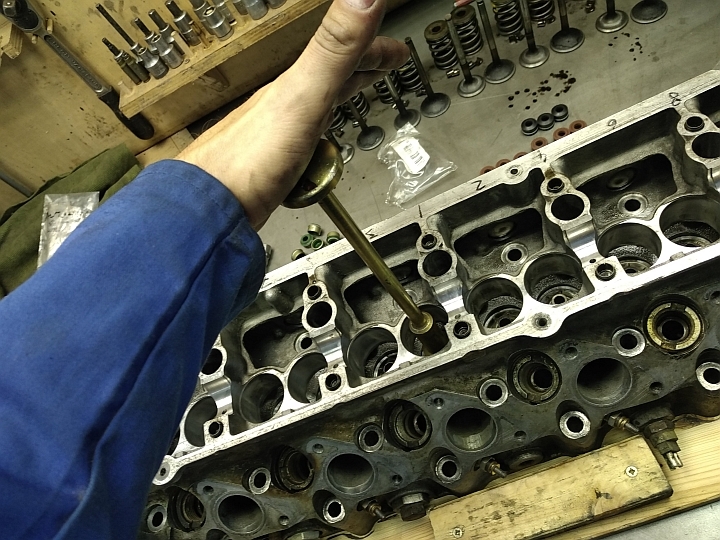

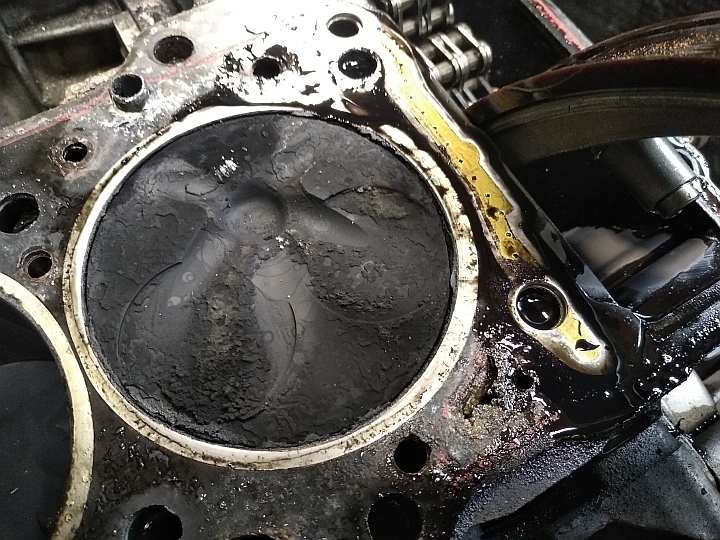

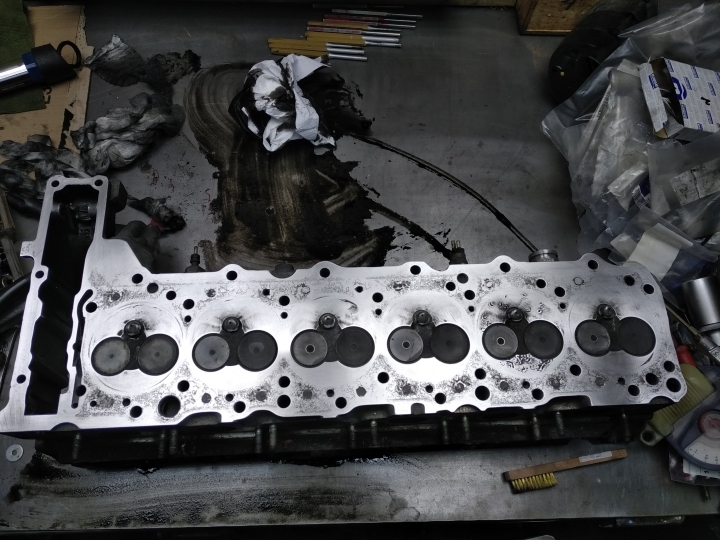

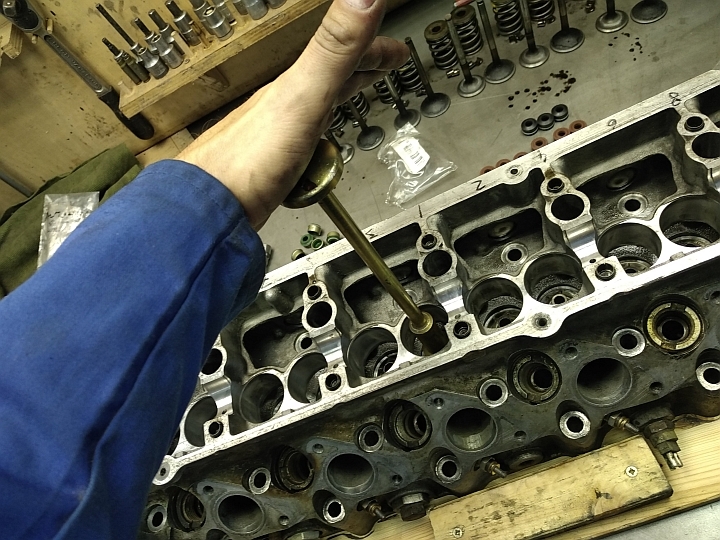

Evening! Lately, this little orange light became a loyal little companion.  Oil consumption of the engine has reached a level that is no longer tolerable. Time to investigate. Off with it's head!  I looks like number 1 cylinder has burned a LOT of oil. Which correlates with the increasing amount of black smoke out the tal pipe...   I looks like the typical head gasket failure. The open channel in the head's surface is the oil feed for the camshaft & lifters. And only sealed by the headgasket. And a blond one away from the cylinder/combustion "chamber". I cleaned up the head... But oh boy. It's not pretty.  Signs of corrosion everywhere. And something I've not seen before; the gas jets coming out the pre chamber have actually eroded the cylinder head.  And last but not least; remember I had to replace a wrong pre-chamber on cylinder number 5? Well, I found out why this had been replaced (probably long before I boght the car). There's a little cross bar inside the pre-chamber. This helps to spread & ignite the injected fuel inside the pre-chamber. They can break off. And subsequently the gas exchange inside the pre-chamber knocks them around which can lead to the tipp of the pre-chamber being knocked off. And it looks like this is exactely what happened here...   Not pretty - but so far it doesn't look like it has caused any trouble... So I'll leave it just as it is. And last but not least I replaced the valve stem seals and lapped the valves. To my surprise there's hardly any wear to the valve train at all.  ^of course you have to use the original MB tool to seat the steam seals, right?  And to my even bigger surprise:  That's not bad at all!!! Especially considering the mileage of this engine. It is at the very least 500-600.000. My estimate would be more like 700-800.000km. But we'll never find out. Anyway, the bores are OK. Not prefect, but not totally polished either. I really hope that the head gasket & stem seals caused the high oil consumption. If not... You'll see me ripping out the engine soon. So long, Jan PS: mileage as of today: 1.111.500 |

| |

|

|

|

|

|

Sept 29, 2019 16:10:58 GMT

|

Unfortunately, I can't report success... No difference in oil consumption. And as soon as I had looked down the bores I knew this is what was to be expected. Because I could look right ontop of the oil rings  The pistons have a ton of slap to them, totaly worn to sh!t... But you know, hope dies last (but it dies...). I have a spare OM603 engine I once bought for 1€. However, after a teardown and close inspection, it doesn't appear to be in any better condition and the cylinder walls suffered from some corrosion. I also have a spare OM603 Turbo engine... But it's in parts and a lot of parts are missing. Chain guides are smashed to bits and the bores are not brilliant either. And there's the issue with a lot of stff that needs to be changed as well, it's not a plug&play engine install. I do also have a OM606 engine & 5-speed automatic trans with all the stuff required to make it run independent. But it's an all-in full blown engine conversion project... No time to do this to a car I need everyday. I do have a very nice OM603 Turbo engine. With ALL the parts to make it go in a sort-of "drop in"-engine conversion. But... No buts. Just a little hurt...  I'm not scrapping the Coupé - but right now it's the best source for an engine I know to be sound. It's going to be a challenge to make it go in a weekend, but I'm positive I can do it. Perhaps with some shortcuts and leaving stuff to sort out later...  Also TÜV will be required. But since I'm not creating a "new" car like I did with the Coupé, this shouldn't be a problem. I've taken everything I need off the Coupé - as soon as I have a full weekend, I'll swap engines. That's all... Mileage: 1.116.100km. Cheers, Jan |

| |

|

|

|

|

|

Sept 30, 2019 7:15:21 GMT

|

Shame about the engine of the taxi, but nothing lasts forever ! Om606 conversion for the coupe ?  |

| |

34 B Ford V8 Flathead Hotrod

55 International L170 (Cummins 6BT)

65 Mustang V8 supercharged Coupe

58 Plymouth Belvedere (Christine)

05 Dodge Ram 1500 HEMI

|

|

|

|

|

Oct 10, 2019 19:26:33 GMT

|

Soooo... Last week I had a marathon wrenching session and basically did the whole - well, almost - engine conversion in a day. Started early in te morning, and by 22:30 it was time to drive it home, with turbo power. Only it was not. More on that later... For TÜV - well, for easy-going-TÜV, I have to basically build everything to factory spec. This meant replacing the engine with transmission, exhaust and diff. And with this a lot of smal stuff in the engine bay, for making use of the factory air filtration etc. etc. Also oil cooler. Out with the old knackered OM603....  And then, the little bits... Like re-routing the hydraulic feed line for the rear suspension to the other side of the engine bay (the Turbo engine uses a different hydraulic pump setup due to clearance issues with the bigger cooling fan). Amongst a lot of other things...  I don't have many pictures, since I was very focused on the task ahead, not often did I think about taking a picture. I had to make use of every minute. But at one point, it was time to put the Turbo engine on the hoist.  Then the exhaust gave me a 2h delay - I had to re-weld the pre-silencer in the end, since it was way off, no way to install it. This slowed progress down significantly. But in the end I had something I could use to drive it home. At some point I'll have to tweak this again, but for now it'll do. A lot of wrenching and sh!t and little things to sort later, and it was time to hook up the battery and give it a try.  It started on the firt flick of the starter - and after 15 seconds it stalled. Started again - ran for 15 seconds - and stalled. I checked everything, bleed all the injection lines etc. - always the same. Runing for 15-20 seconds and then stalling. After about 1h I gave up. There was no evident fault, everything hokd up as it was supposed to. I hadnoticed that the stopping lever was pulling down by itself, stopping the engine. When I held it up, the engine ran flawless. Not a fault I had heared of before, nothing that was explainable to me. It did it without the vacuume hose attached - just if you wonder  So - completely puzzled I ordered a train ticked and had to call another Taxi to get home  Next day I woke up sick, pucking & sh!tting out my intestines - no worky worky... This tied me to bed a couple of days. Time to think about it and research the issue with the engine. No clue. Nothing made sense - except a somehow broken pump regulator. But why!? And how!? The solution however was laughably simple really. But tricky. By sheer coincidence I opened the oil filler after the engine had stalled. And there was a lot of pressure escaping when I opened it. And in this very moment I realised: I'M AN IDIOT!!!  I had plugged all openings on the engine, after I pulled it and stored it away for a couple of days. Including the crank case ventilation. I didn't remove this plug... So pressure inside the crank case built up - and pushed up the membrane of the stop lever and thus stalling the engine. Good Lord, I would have never thought about that!!  Anyway... Pulled the plug - and I ran sweet as a nut.   If you know your W124s - you may notice that something's missing. Yepp - no slots in the wing! I'm keeping it a stealth turbo. And for this reason, I once bought a very rare part - the under-fender-air-intake. As far as I know, these were only used on the very first Turbo cars on the US market.  I like it! Saves me painting a wing and keeps it low profile... That's it for now. But there's still work left to do... Mainly - re-installing the aux heater!! For now I removed it to make room for the air filter housing thingy. But I have al the parts to put it back in, just in a different location.  Cheers, Jan Oh - in case you are wondering. I absolutely LOVE this engine!! It's strong and sooo relaxed to drive... 100% awesome!! It was worth the effort and I'm glad I did it!! So nice to get puled along by the grunt of the turbodiesel. It's realy the best engine in the world! Well, for commuting at least. Not so much for racing...  |

| |

|

|

|

|

|

|

|

|

I cannot enjoy any thread more than this. Most excellent!

Spannering skills turned up to 11!

|

| |

|

|

|

|

|

Oct 11, 2019 10:08:21 GMT

|

|

good stuff...always enjoy your posts

|

| |

91 golf g60, 89 golf 16v , 88 polo breadvan

|

|

|

|

|

Nov 14, 2019 20:23:44 GMT

|

Well... I think it's the first time that the car is off the road due to breakage. Couple of days ago I was just enjoying the benefits of turbo-charged diesel engine acceleration capabilities. Wehn suddenly there was a big *POOOFFFFFF!!!!!* and cooling and steam (LOTS of steam!) came out all the vents in the dashboard. Yay! So I shut the heater off, topped up the coolant every couple of kilometers and finished my daily commute to work. Freezing. After Feierabend I bypassed the heater, making use of scrapped W126 heater pipes & 190E hoses.  Of course it had to happen this time of the year, right?? Amazing how fast windows can fogg without a heater. And how freezing cold it gets. Really nothing but a temporary measure. So Tuesday when I had all parts I started pulling it apart. So currently I'm driving a modern contraption, some sort of Toyota with a Subaru badge on it... To get to the heater core, everything needs to be removed. Everything.    Safe to say that I found why there was so little air comming through the heater    Disgusting!! That's 30 years and 1.100.000km worth of dirt in there... And that's actually a surprise; vaporiser & heater core are still original from 1989!! Which might explain why it exploded. All the rubber seals are hard and brittle. No surprise.  All that's left now it putting everything back together as it was.... Hahaha. That's all... Cheers, Jan |

| |

|

|

|

|

|

Nov 15, 2019 15:22:12 GMT

|

|

ARRRRRRRRRRGH!

Supposed to be one of the wrost jobs ever on a W124. I hope your time in the Suboyta is limited, and that toasty feet and fog free glass come to you very soon.

|

| |

|

|

|

|

|

Nov 15, 2019 20:11:51 GMT

|

Well to be honest - it's not that bad really... Extracting the heater unit took me about 1.5h. Though I've done it a couple of times before  On cars from '89 onwards (face lift) it's a bit tricky, since they went from a rubber seal on the firewall to a sticky foam seal. Getting this off without breaking the heater box can be challenging. And worst of all; the firewall seals are not available anymore... Mercedes doesn't supply them anymore. But... It looks like the expanding foam band that's used with windows or other construction stuff is pretty much the exact same thing - and cheap as chips! But since my car is a pre-facelift it's got the reusable rubber seal  Put the heater box back togehter this evening. New heater core and new A/C vaporiser.  Cheers, Jan PS: The Toybaru is not bad - same MPG as the Taxi, but going 30km/h faster  |

| |

|

|

|

|