Sir Overdrive of Kineff asked how I cleaned the head. So here we go. Warts and all. Probably in more detail than anybody could want.

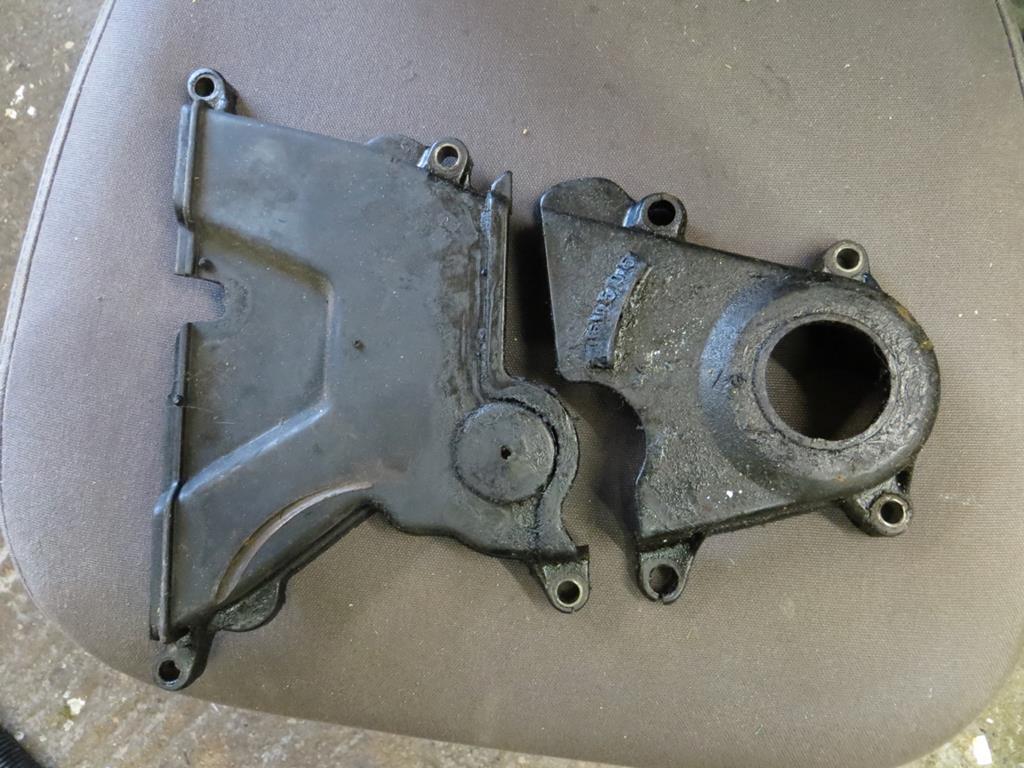

Lets start with the small stuff. Nuts and bolts and brackets and stuff.

The weapon of choice is my home made media blaster.

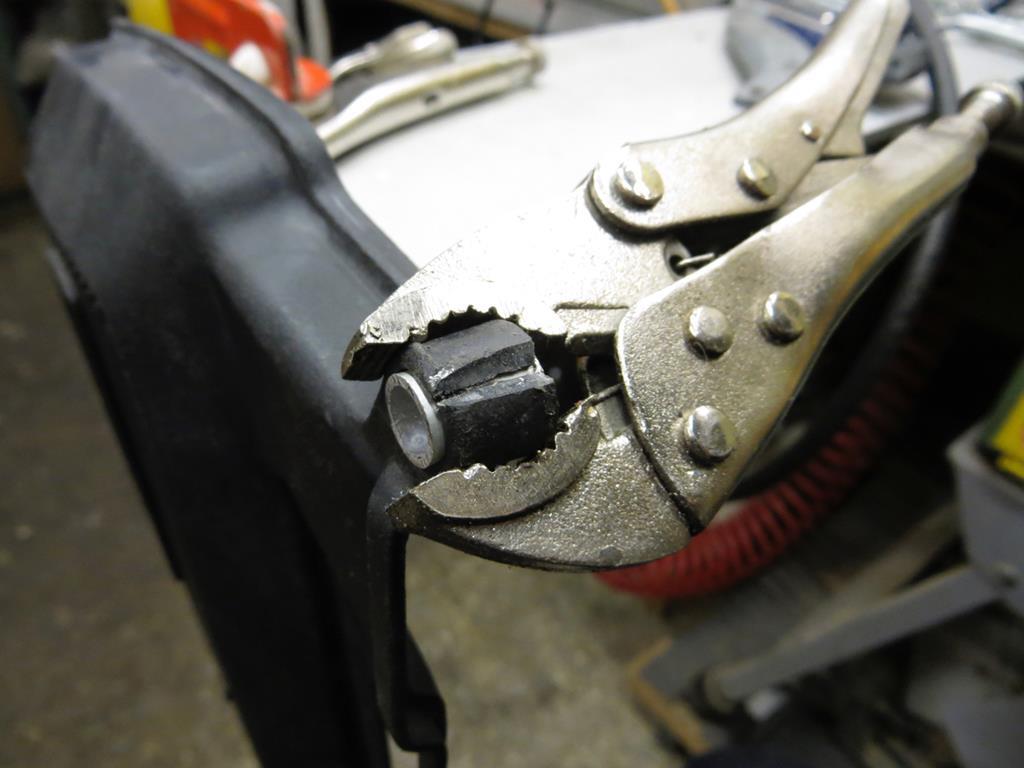

But things have to be pretty clean before they go in. Claggy oily dirty goo will not come off in the blaster. Well it will but it takes ages so you are better off cleaning it first.

For this I do a bit of scraping with screwdrivers, bits of stick, whatever I've got, and a lot of washing in the sink with brushes. One of the best things I have is an outside sink. Dead handy 'cos I can make a mess and not get told off by the missus.

We need a solvent. I use a few that I happen to have handy depending what I'm working on.

1, The previous owner of our house left a large tub of Swarfega. Squirts of this with a tooth brush or a brass bristled brush works well. The part has to be dry first though.

2, Good old washing up liquid.

3, And surprisingly, WD40. I hate the stuff and think it has almost no place in a modern garage but it's outstanding at breaking down oily crud. And with a bit of effort it brings up hoses nicely too.

You can see these aren't totally clean yet and need another go with WD40. It's a tedious job but they look good in the end.

Cleaning gets us from this...

To this...

So once "clean" they go into the media blaster and come out looking like this...

For stuff in the head this is fine. The oil will stop it rusting. But here's a bolt that was blasted and then left in the garage for a few months.

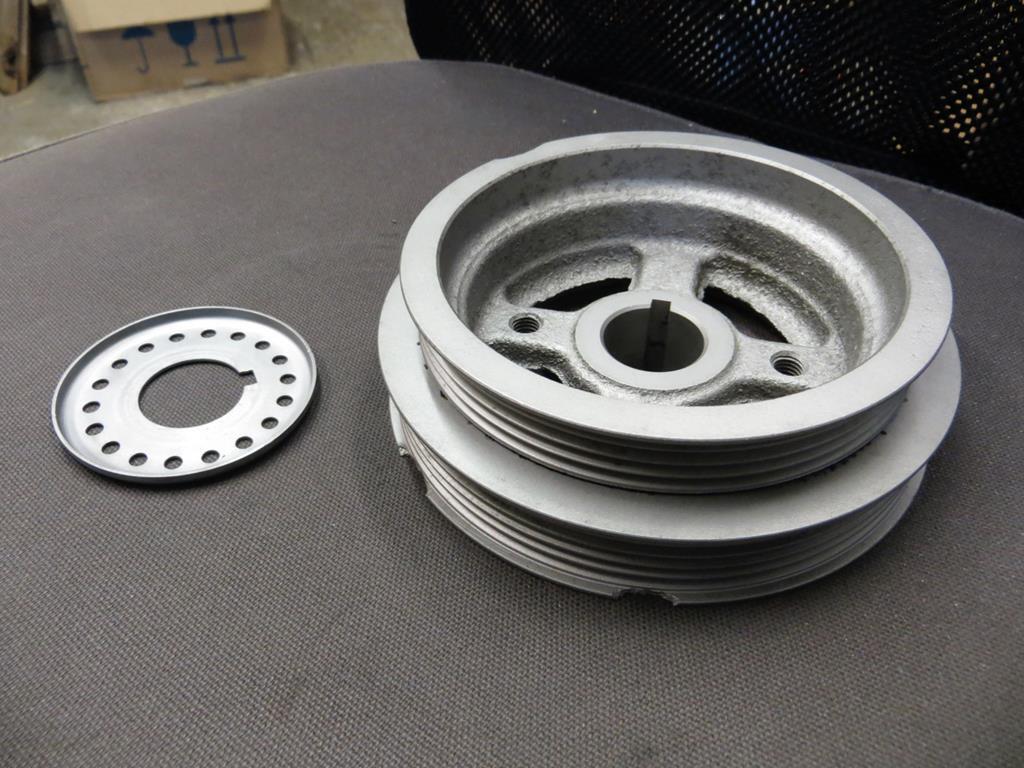

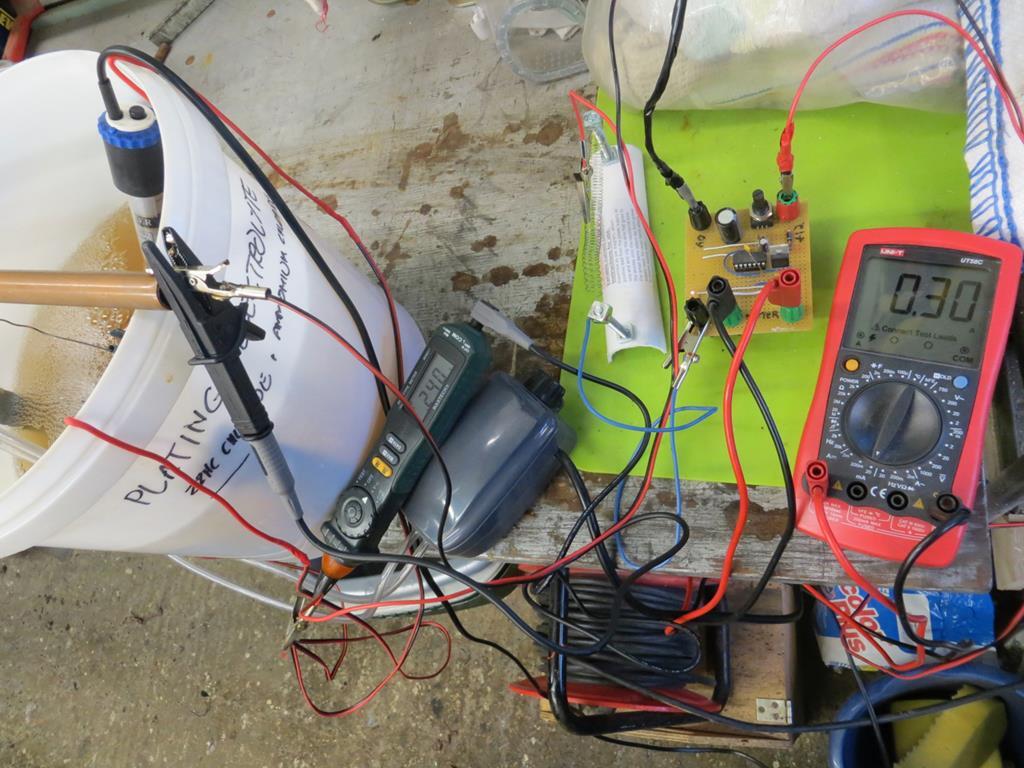

So it needs a protective coating put back on and I'm zinc plating mine. Eventually things will like something like this...

But the process is causing me serious grief at the moment so let's forget about it. It's just too painful a topic and will make me burst into tears. Boo hoo...

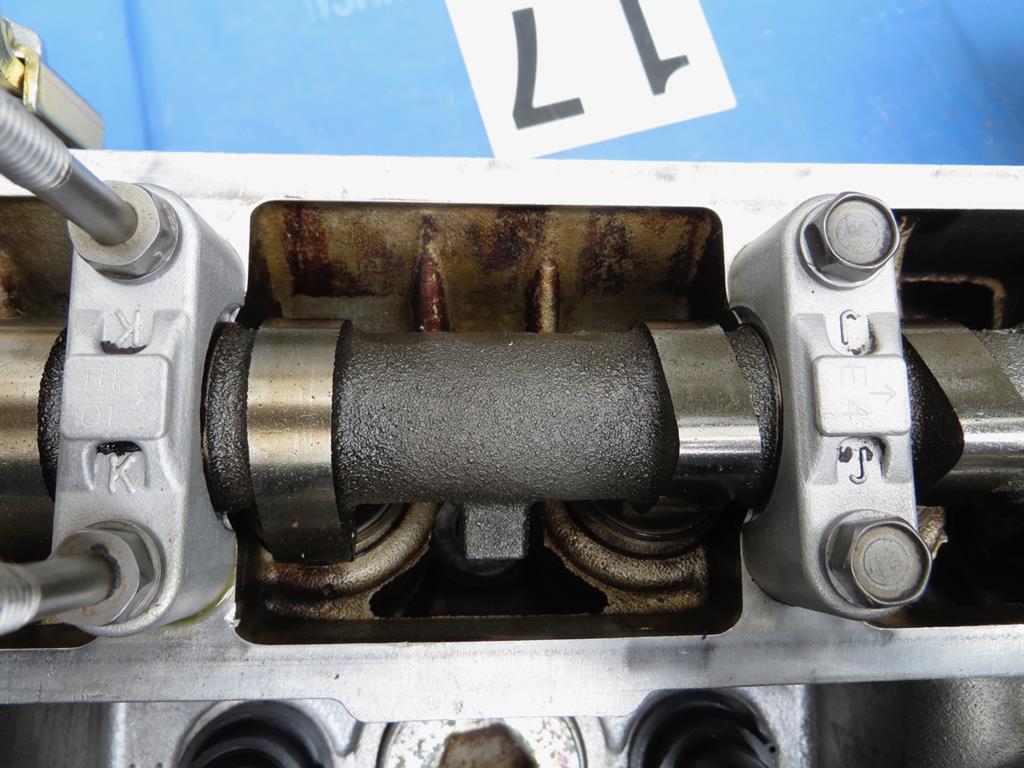

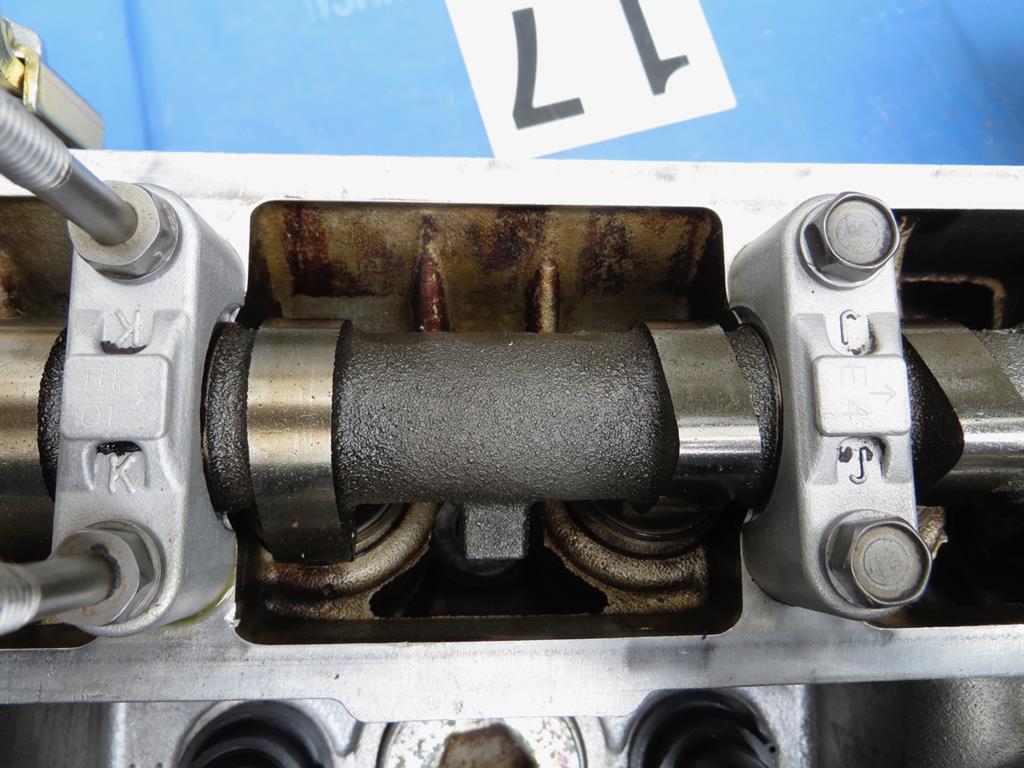

Moving on to the cam shaft bearing caps, I very nearly didn't bother cleaning these but then a sudden attack of OCD came over me and I was compelled to tart them up.

Same process. Wash in some solvent (Swarfega I think) then in the blaster. BUT... The blaster will damage the bearing surfaces so they must be taped over before they go in. The cam shells are aluminium and I'm using glass bead in the blaster. It's not as harsh apparently but it will still dull the bearing surface even of steel so aluminium stands no chance. Occasionally I manage to pull the trigger of the blaster while I'm refilling its bottle. Glass bead bounces off the inside of the blaster and hits me in the head. It bloody stings! In fact it's fogging the glass window of the blaster so I'm going to have to replace that soon.

Compressed air at 100PSI isn't safe. Fill it with glass and it's downright dangerous.

The cams got exactly the same treatment as the shells. Washed with a solvent (Swarfega probably or washing up liquid) then the bearing surfaces and lobes are taped. Then off in to the blaster. Except...

When you use the blaster you get a very fine dust produced.

This and the glass bead will pack into any hole they can get into. Notably threaded holes which are often very difficult to clean again. So it's often worth putting a bolt into them to save yourself a problem later. I did this with the cams. I stuck the pulley bolt into the end.

One other thing about the blaster... The cam shafts on the 4A-GE have an oil way drilled down the middle. Absolutely without doubt the worst place to get glass bead would be in the oil galleries. So I paid particular attention to taping them up.

The brown staining on the bottom of the cam lobes was removed with WD40 on a rag.

And lastly the cam pulleys were just washed with Swarfega. I didn't blast them because they didn't need it and I didn't want to risk damaging the surface the belt sits on.

So let's think about the distributer next.

I needed to blast the outside to get the finish I wanted but you can't take it apart without removing the pin that holds the drive gear on. I didn't want to do that because you can't reuse it. I could have closed the top with the distributer cap except it was trashed...

So I taped a glass bottle over the top and wound gaffer tape round the drive end. I also put the screws in the holes to keep the threads clean. That leaves some drain holes in the bottom to block up. I stuck short pencils in these. Then it went in the blaster. I wish I could show you a photo with the pencils jammed in it but sadly I didn't take one.

The point is, tape up or protect anything that could be damaged by dust or bead. It gets everywhere. Absolutely everywhere.

So the head... Clearly the idea would be to bead blast it. And I thought this over for some time.

I could tape the cam journals and stick pencils or sticks in the valve guides but what about the rest of it? What if a pocket of glass bead didn't wash out and wound up in the oil. Hmmm. Not liking that idea.

So I played with a home made parts washer. Here it is...

The white cylinder is a 12V water pump. a few quid from Amazon.

Water is sucked up the bottom and blown down the clear tube.

And the plastic things in the bottom are just to stand the part out of the liquid to create a sump.

The liquid was the next problem. Many people use diesel or paraffin but I didn't have that much of either and I wasn't sure how the pump would feel about it. So I actually used hot water from the tap and a washing machine tablet. I believed too many adverts about stain digesters and things.

This sort of works but not quite as well as I'd like. I'd dearly love to chuck things in the box, turn on the pump and leave it alone but that's not going to happen. Also the water goes cold too quick and half the cleaning power is the heat in the water. My little fish tank heater didn't help 'cos it wont get the temp up that much. I need 50 to 60 C which would boil your average fishy. (Hmmm, snack sized fish and chips. I'm just off to make my fortune!)

For a future development I need a bigger heater and some sort of brush with a pipe through it. Bit like washing your car with that brush on the end of a hose. Just smaller. That way I could scrub and wash away the dirt.

So the head had a couple of trips through the "parts washer" and some time in the sink being rubbed with washing up liquid and swilled out with hot water. The last tool in the armory is this...

Filled with hot water and, maybe, washing up liquid. It's good for blowing through confined spaces. Oil galleries and stuff. Messy though and you need to hook up the compressor.

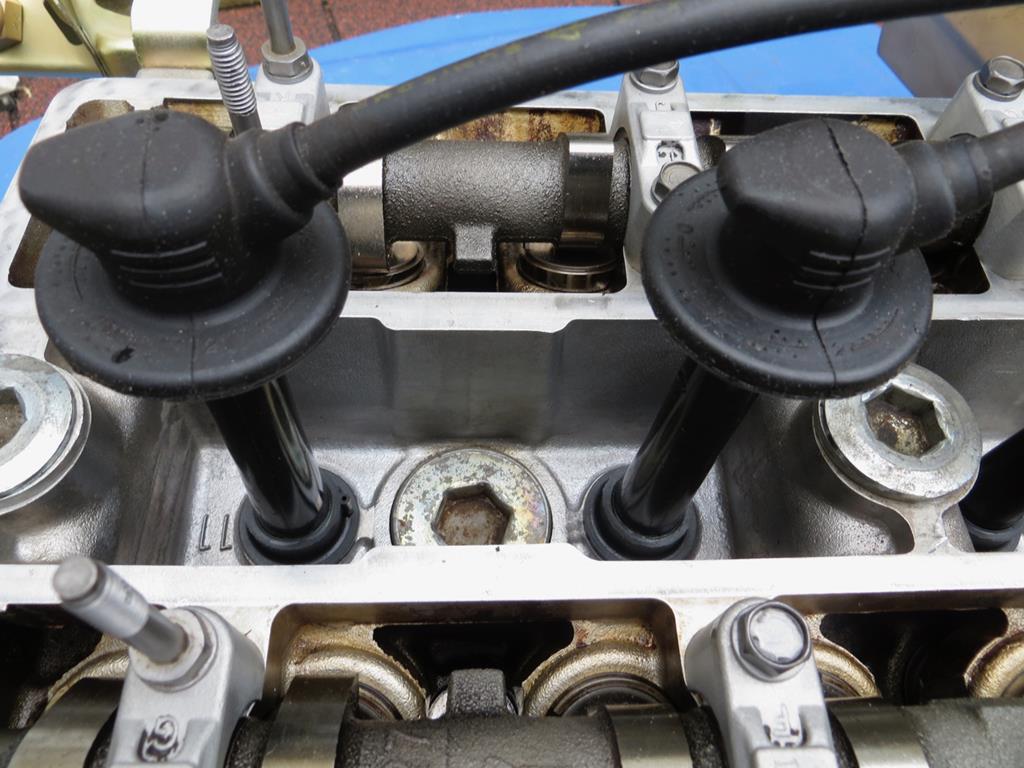

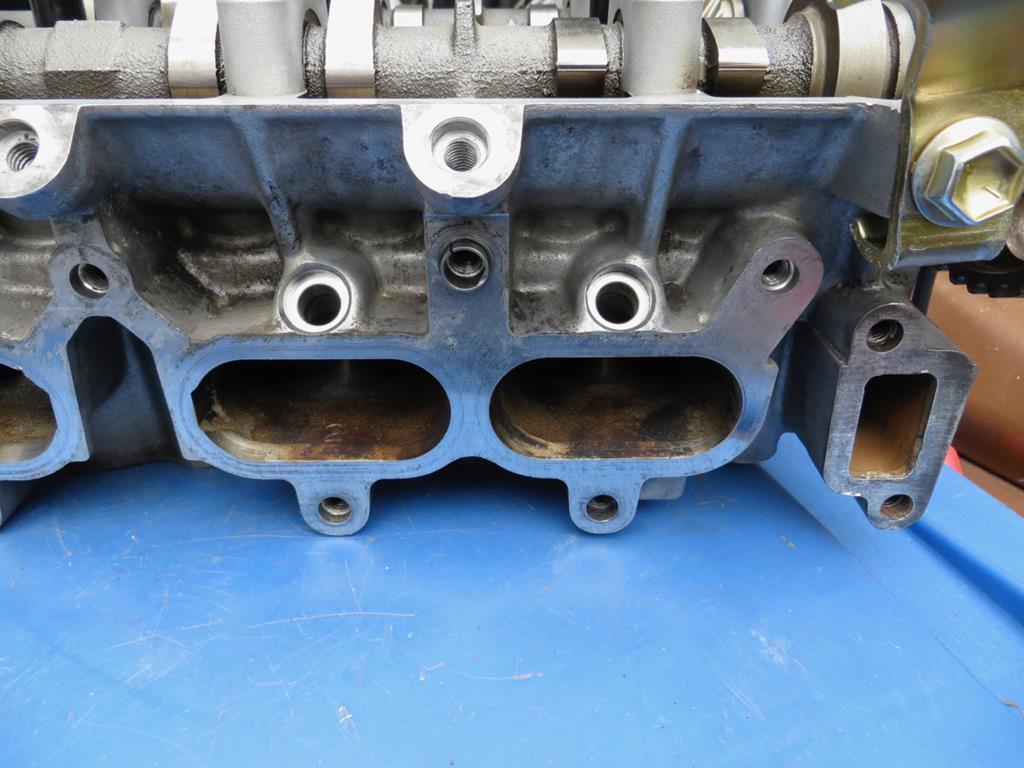

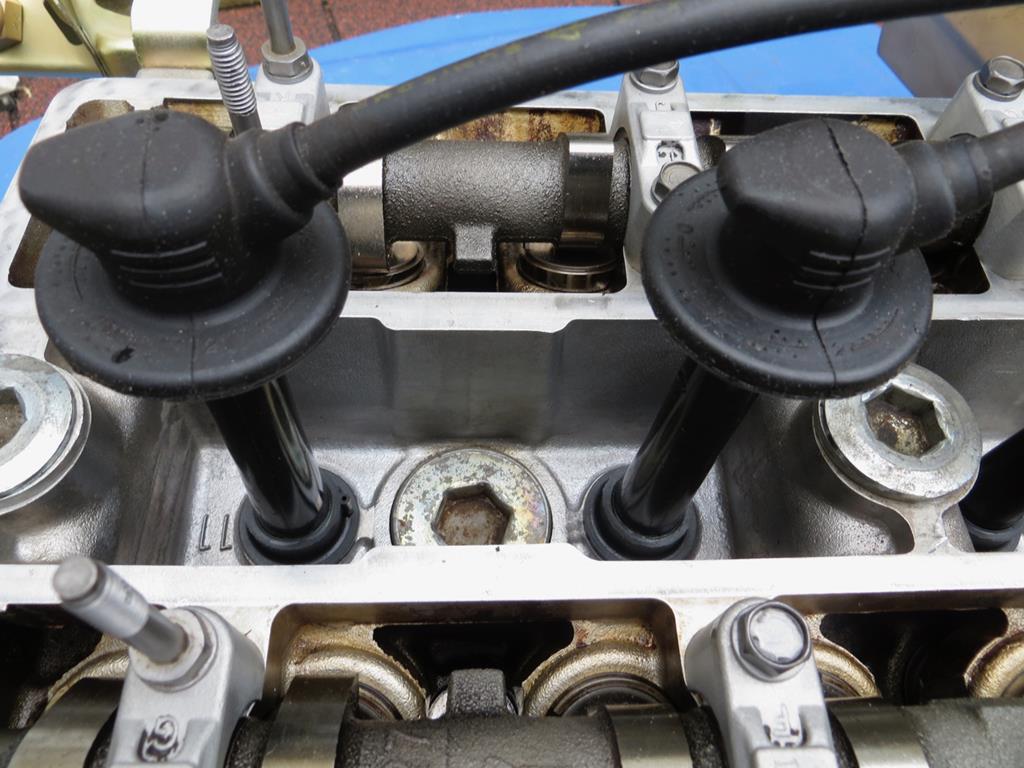

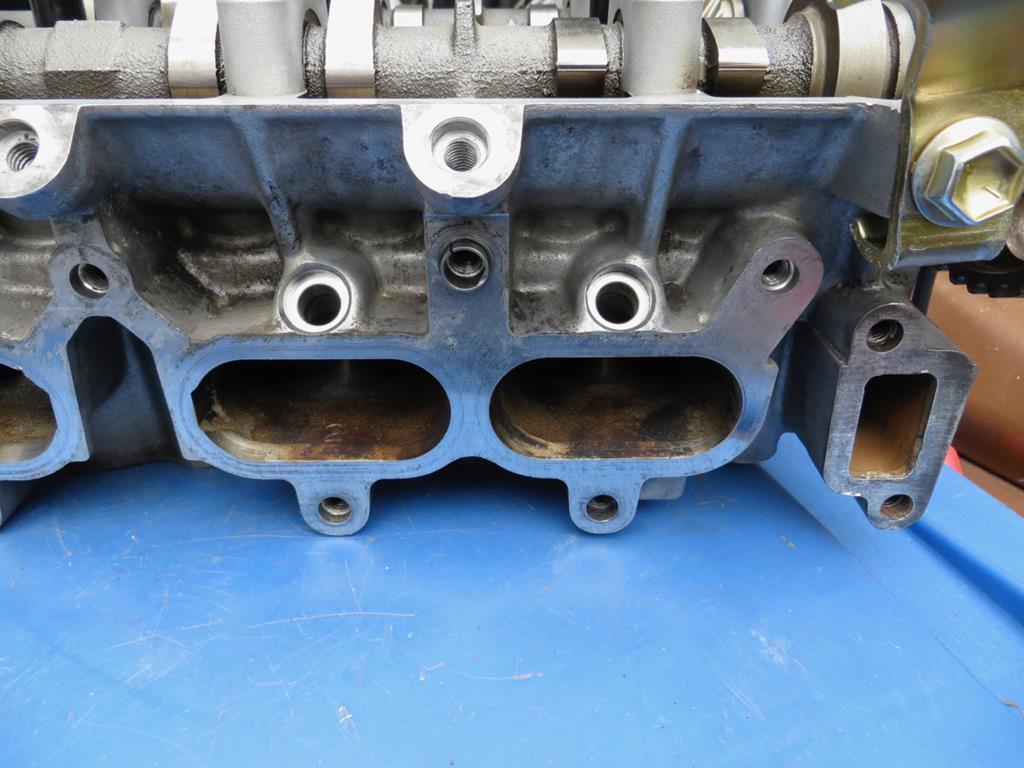

Here are some photos of the head.

The dizzy case came out of the blaster nicely.

The internals still have brown staining from the oil but it's much better than it was.

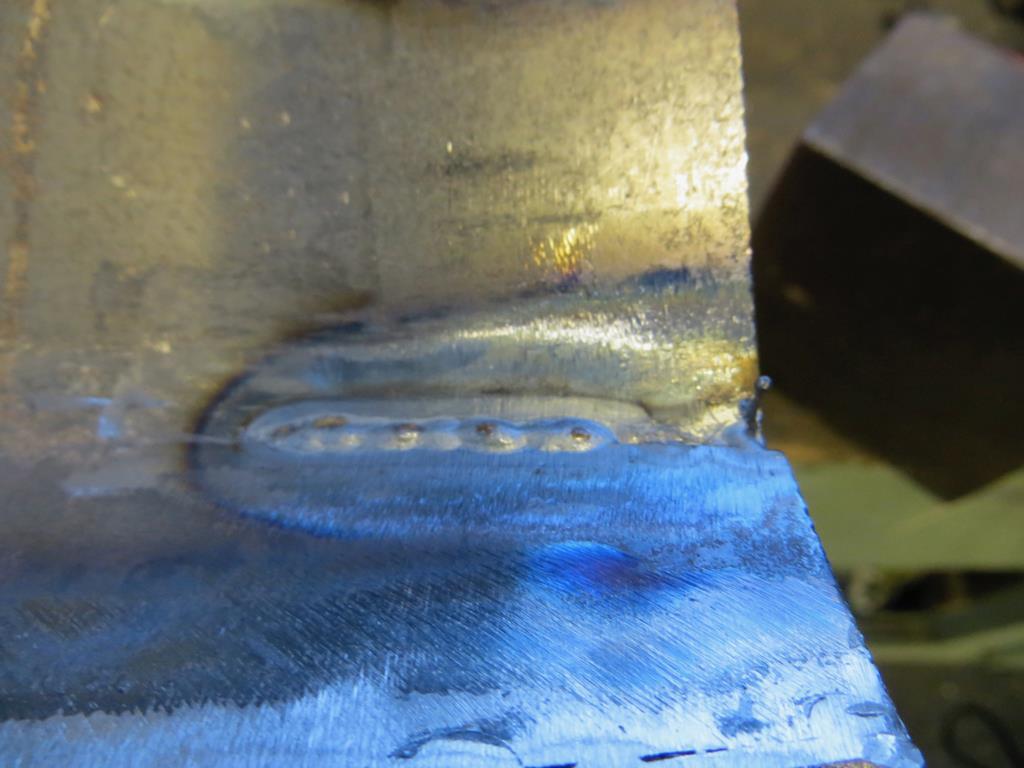

You see the black marks on the cam journals? That's where I didn't get all the clag off in the sink and the bead blaster hasn't moved it either.

The plug valley is looking reasonable.

Exhaust port side.

Some staining above where the manifold would be. And it hasn't touched the carbon deposits.

Inlet port side.

There is actually bits of oily clag in the recesses above the ports. Pathetic job I did there!

It's not brilliant but it's a vast improvement. You wouldn't want to eat your dinner off it but at least I can handle it without getting covered in mank.

So that's about it. Serves you right for asking!

James

I may still have one knocking about ill phone home and let you know

I may still have one knocking about ill phone home and let you know  We filled them in with black mostly, but this is the only pic I have to hand.

We filled them in with black mostly, but this is the only pic I have to hand.

The plating is something i'd love to be able to get right as it adds That OEM look to an engine bay. keep it up!

The plating is something i'd love to be able to get right as it adds That OEM look to an engine bay. keep it up!