|

|

|

|

|

Thanks tickman . I had some time off work which helped but now I've had to go back.  I did try and tell them there was a financial benefit if they paid me to stay away but they wouldn't have it. Sadly Mrs Sweetpea has been saving jobs up while I've been messing with the car too. There is a small pile of oak in the back room which needs to box in the landing window. I think that might be tomorrows job. James |

| |

|

|

|

|

|

|

|

Nov 24, 2015 18:05:26 GMT

|

Ah, so, Grasshopper strives for perfection.. A quick shot of the repair. So this is welded, ground back and with a quick coat of POR15 to keep the rain off. The obvious line across the panel is actually where I ground the paint off. The weld line is just below it. You can see it in the original photo but probably not in this smaller one.  I guess the question is - what am I actually aiming for? Well I'd like to make, weld in the patch and then make good with a couple of coats of high build primer. Clearly if I achieve this Rolls Royce will be begging me to be their chief engineer. So, in the real world, if I can make good with a THIN skim of filler I'll be happy. I haven't looked closely but I think this one is in the 'thin skim of filler' ball park. Good but I'll keep striving for better. In the next episode I'll be welding while standing on one leg on top of a fence post. And in the one after that I'll be recovering in hospital. "Patience young Grasshopper." |

| |

Last Edit: Dec 20, 2018 22:12:05 GMT by Sweetpea

|

|

Rebel

Part of things

Posts: 343

|

|

|

|

|

Just a quick useless fact - did you know that your rear axle is from the front of a Toyota Corolla ( you should be able to see the Corolla tie rods still in place under the rear bumper ). Designed this way by Toyota

|

| |

1968 Dodge Charger

1985 Chevrolet Camaro

1993 Toyota Hilux Surf

2001 Ford Mondeo

|

|

|

|

|

Dec 15, 2015 20:35:27 GMT

|

Sorry Rebel, I was away on a course and then on nights. Only just catching up with my own thread! Er, yes, I sort of did know that. Actually I think it's a bit of a cross between the earlier KE70 and later EE80. It's got the drag links all round like the KE70 or the back of an EE80. But the front 'sub frame' is a very similar design to the EE80s front. I've always wondered if there are bearings in the top of the MR2s rear struts. If there are you could put a rack on the back and have 4 wheel steering. Fun but pointless! James |

| |

|

|

|

|

|

|

|

That was your 600th post. Well done. I'm going to have to write a lot more drivel before I get to 600. I notice that you are now at 300 posts, and at page 20, which implies that you have another 20 pages or so worth of work cut out for you! Luckily, your...determination to do the job right, also ensures that the rest of us probably will have 20 more pages of enjoyment to read! |

| |

|

|

Rebel

Part of things

Posts: 343

|

|

|

|

Sorry Rebel , I was away on a course and then on nights. Only just catching up with my own thread! Er, yes, I sort of did know that. Actually I think it's a bit of a cross between the earlier KE70 and later EE80. It's got the drag links all round like the KE70 or the back of an EE80. But the front 'sub frame' is a very similar design to the EE80s front. I've always wondered if there are bearings in the top of the MR2s rear struts. If there are you could put a rack on the back and have 4 wheel steering. Fun but pointless! James No problem, life in general always gets in the way of fun, lol. rear wheel steering, now there's a thought. It could probably be Toyotas version of the 4ws Honda Prelude, they were fun ( as long as you didn't try to change direction mid corner, lol ) |

| |

1968 Dodge Charger

1985 Chevrolet Camaro

1993 Toyota Hilux Surf

2001 Ford Mondeo

|

|

|

|

|

|

|

I notice that you are now at 300 posts, and at page 20, which implies that you have another 20 pages or so worth of work cut out for you! Luckily, your...determination to do the job right, also ensures that the rest of us probably will have 20 more pages of enjoyment to read! 300 posts... I hadn't noticed! I can't quite believe you are looking forward to another 20 pages though. That's above and beyond the call of duty! |

| |

|

|

|

|

|

Dec 16, 2015 22:19:34 GMT

|

That's the best 20 pages of a readers thread I've enjoyed for a while. I had to join up just to show my appreciation, so here is my first post as a new member doffing my cap to you for sharing your epic adventure. I have a subtly modded 924S and considering the cars are practically the same age it's amazing at how rotten the MR2 has gotten in comparison, what did they make it from?  ive never read anyone that's as tenacious and dedicated to taking on a project like this and then finding every which way to refuse to throw any broken part in the bin. I've laughed my way through the whole thing, is there anything you can't do. your welding is simply inspiring as is your ability to fabricate any shape that car seems to throw at you, your patience with that bumper had me in stitches. thankyou for sharing and I like many others look forward to the next 300 posts, it'll actually be an anti climax when you've finished it. cheers Jeremy. |

| |

Last Edit: Dec 16, 2015 22:34:21 GMT by j3shf

|

|

|

|

|

|

|

That's the best 20 pages of a readers thread I've enjoyed for a while. I had to join up just to show my appreciation, so here is my first post as a new member doffing my cap to you for sharing your epic adventure. I have a subtly modded 924S and considering the cars are practically the same age it's amazing at how rotten the MR2 has gotten in comparison, what did they make it from?  ive never read anyone that's as tenacious and dedicated to taking on a project like this and then finding every which way to refuse to throw any broken part in the bin. I've laughed my way through the whole thing, is there anything you can't do. your welding is simply inspiring as is your ability to fabricate any shape that car seems to throw at you, your patience with that bumper had me in stitches. thankyou for sharing and I like many others look forward to the next 300 posts, it'll actually be an anti climax when you've finished it. cheers Jeremy. Jeremy, thank you for your very kind post - and welcome to the forum. Unfortunately my head is now too big to get through the garage door. Not to worry though, Mrs Sweetpea will soon fix that. (Oops, hope she doesn't read that...) Get a thread started about your 924, there are a few good Porsche threads on here but always room for another. Interesting point about the rust. I think mine is typical of a MK1 MR2 and certainly better than some. I deliberately went for a project so I could learn something new so it shouldn't come as a surprise that there are a few holes in it. Toyota always had a reputation for reliability but it's less obvious that they built cars with a specific life in mind and did it incredibly well. What I mean is that if you have enough of them for long enough they "fall apart reliably" too. Now that's truly impressive. I guess my MR2 is at around twice it's design age and about it's design mileage. All the bits that I'm dealing with now would have caused no bother during the cars service life. Although, being fair, Toyota did mess up with the rear arches on the MR2. As always, some seemingly identical cars will survive better than others and I've never quite worked out why that happens. Anyway, can't sit here chatting... Having prattled on about Toyota's stunning ability to run and even breakdown reliably it sounds like the exhaust is falling off my modern Lexus. Ah well, the exception that proves the rule and all that... I'm not even sure the ramps will go under it. I've never had to try. Thanks again for your kind words. James PS - don't worry, the MR2 will never be finished. At some point they'll bury the car and chuck my ashes in through the sun roof. |

| |

|

|

oukie

Part of things

Posts: 307

|

|

|

|

That's the best 20 pages of a readers thread I've enjoyed for a while. I had to join up just to show my appreciation, what did they make it from?  cheers Jeremy. I know the answer to this question, Toyota were importing steel from Italy in the 80's, NOT a joke. Where the problems start is in water drain design, it drains through the chassis basically, the sunroof has little pipes that only go so far down the a pillers, then as the water is meant to run out of little drainage plugs, these can block, this plus the salt put on the UK roads is a killer combination. The mk1's that have survived this long are and were cars that have probably been garaged for most of the time either at an early stage or at some point etc. |

| |

Mr2 mk1 x4

Honda Accord 2.4 Executive (luxo barge)

|

|

|

|

|

Dec 17, 2015 11:15:01 GMT

|

I know the answer to this question, Toyota were importing steel from Italy in the 80's, NOT a joke. Where the problems start is in water drain design, it drains through the chassis basically, the sunroof has little pipes that only go so far down the a pillers, then as the water is meant to run out of little drainage plugs, these can block, this plus the salt put on the UK roads is a killer combination. The mk1's that have survived this long are and were cars that have probably been garaged for most of the time either at an early stage or at some point etc. I don't know where they got steel from in the 80s but basically I have to agree with that. You have to compare these things against the other cars of the day though. Our first Toyota was a 1979 Corolla. That was up against MK2 Escorts. The Corolla was quieter, nicer and better equipped than the Escort. More importantly when you set off in the morning the Corolla was going to get you home. With the Escort that was a complete lottery. But the rust was unbelievable. If you got a stone chip in the paint and didn't fill it in you'd wind up with tentacles of rust running under the paintwork. I've only seen that on British Leyland cars of the period but I'd imagine Alfas did it too. Our next Toyota was a 1983 Corolla. By then Toyota had gotten a bad reputation for rust (very well deserved too) and had pretty much sorted it out. Corollas of the 80s did rust but no worst than Fords or Vauxhalls of the period in my opinion. Looking at project threads of 80s and early 90s cars on here, they mostly have rust problems. They just weren't designed to last this long. Dear old dad briefly had a Metro in the late 80s and that needed new sills during it's supposed service life. Even my old 79 Corolla didn't need sills and you could practically watch that dissolve on the drive... Dumping the sunroof drains into the sills was a really dumb idea though. But then I think practically all manufacturers did that at the time. And let's face it, if you had a car with a sun roof in the 80's you were proper posh. When I get round to taking the wings off the MR2 I'll reroute the drains somewhere else. One of the interesting challenges of keeping older cars going is working out why they rusted away in the first place and stopping them from doing it again. James |

| |

|

|

oukie

Part of things

Posts: 307

|

|

Dec 17, 2015 16:07:00 GMT

|

|

Hi, James, you could just extend the hoses to run right out the bottom instead of it draining into there, if you get my meaning, I believe that several other mk1 coupe owners have done this mod.

|

| |

Last Edit: Dec 17, 2015 16:09:59 GMT by oukie

Mr2 mk1 x4

Honda Accord 2.4 Executive (luxo barge)

|

|

|

|

|

Dec 17, 2015 23:40:30 GMT

|

|

I don't agree that the steel was inferior quality. I reckon it's more to do with how they were treated, washing/underbody treatment etc.

We used to see 1980's corolla's etc that except for some paint fade were still solid as a rock, whereas I've worked on 1 yo 4WD's where the whole drivetrain is rusted from never being washed after being on the beach.

It's the same reason why people in the US try to get classic cars from southern California, Arizona etc, rather than the northern states. Same car, same metal different conditions.

|

| |

|

|

|

|

|

Dec 18, 2015 11:06:58 GMT

|

how very dare you !!! 80s vauxhalls were electrogalvanised/dipped on the production line, and then electrostatically primed !!! well, the two used for the brochure were anyway   |

| |

Last Edit: Dec 18, 2015 11:09:27 GMT by darrenh

|

|

oukie

Part of things

Posts: 307

|

|

Dec 18, 2015 13:20:06 GMT

|

I don't agree that the steel was inferior quality. I reckon it's more to do with how they were treated, washing/underbody treatment etc. We used to see 1980's corolla's etc that except for some paint fade were still solid as a rock, whereas I've worked on 1 yo 4WD's where the whole drivetrain is rusted from never being washed after being on the beach. It's the same reason why people in the US try to get classic cars from southern California, Arizona etc, rather than the northern states. Same car, same metal different conditions. There is truth to this also, I have a Japanese import supercharger, salt is not put on the roads in Japan so mine is/was less rusty but still not mint, I've seen imports that look brand new underneath etc, it's like you say how there looked after ie garaged etc, which marks out the survivors. Sorry for the thread hijack, James. |

| |

Mr2 mk1 x4

Honda Accord 2.4 Executive (luxo barge)

|

|

|

|

|

Dec 18, 2015 19:00:57 GMT

|

Sorry for the thread hijack, James. No problem. I have a vested interest in the subject since I don't wish to spend my entire life replacing the same bits of car over and over... Anyway, I'll claim the thread back shortly. I have more photos and stories to bore you all with! how very dare you !!! 80s vauxhalls were electrogalvanised/dipped on the production line, and then electrostatically primed !!! well, the two used for the brochure were anyway   And I thought I was going to be in the dog house for slagging off MK2 Escorts! I've been reading chris y 's Carlton thread (here if you haven't seen it) and, frankly, if that was gavanised it didn't help much. Anybody know what the process was / is? Do they electroplate the panels and then weld them together? Or do they build the car and then electroplate it. I ask because I thought it was the latter - but electroplating is a line of sight thing which would leave all the important bits (sills and seams) unplated. James |

| |

|

|

|

|

|

Dec 20, 2015 13:33:36 GMT

|

just a bit of banter  kind of an ironic quip based on how bad they still rot. i'm very critical and self deprecating when it comes to old vauxhalls despite owning them for 20 years now. but yeah the brochure claimed that zinc coated steel was used for pressing certain "at risk" body panels, got picture of shells being dipped post assembly and zinc phosphate E coat (sprayed) post assembly. i think the whole charade falls apart at this point.... "polymer reinforced anti corrosion wax pumped into doors, sills and other underbody cavities" i call major BS on that one! |

| |

|

|

johnl

Part of things

Posts: 20

|

|

Dec 20, 2015 15:28:33 GMT

|

|

The panels would normally be electroplated priorr to being spot welded together. I have an old pair of sills for my Mazda and they are coated both sides.

Nothing lasts forever, the rust I see on UK cars due to salt you'd never see in Australia. Anything modern say post 1980 would be crushed before any significant rust occurred. The amount of really rusty modern cars such as your MR2 are simply not seen here even if you went through a wrecking yard !

Salt is a corrosive, once enough builds up within cavities it's going to rust. Protective coatings can only go so far.

|

| |

|

|

|

|

|

Dec 20, 2015 17:59:03 GMT

|

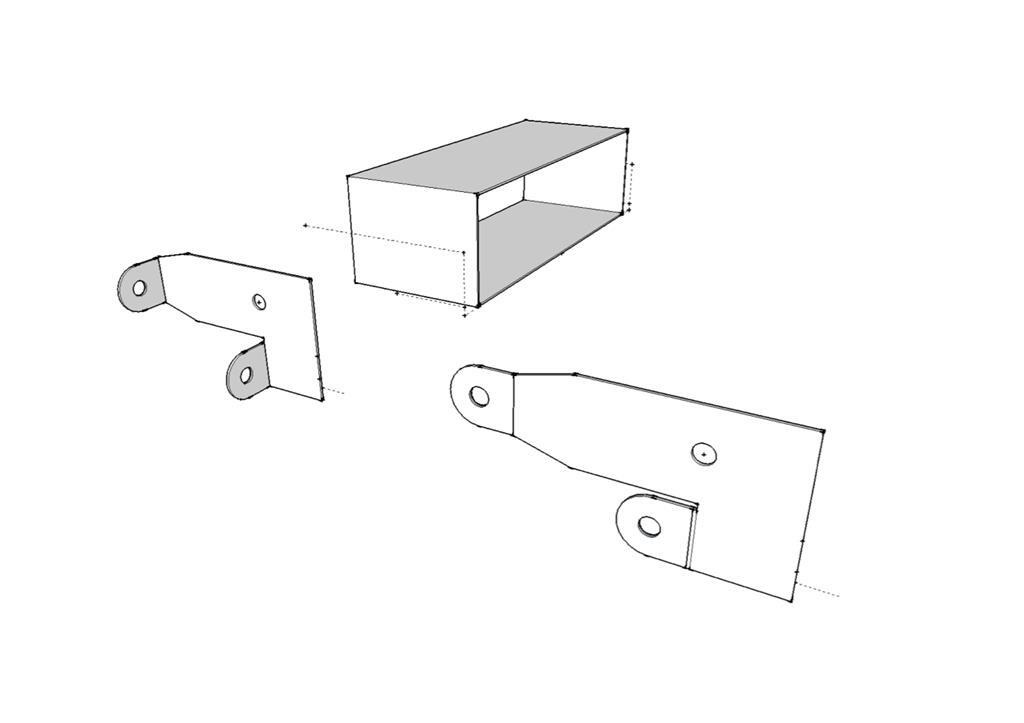

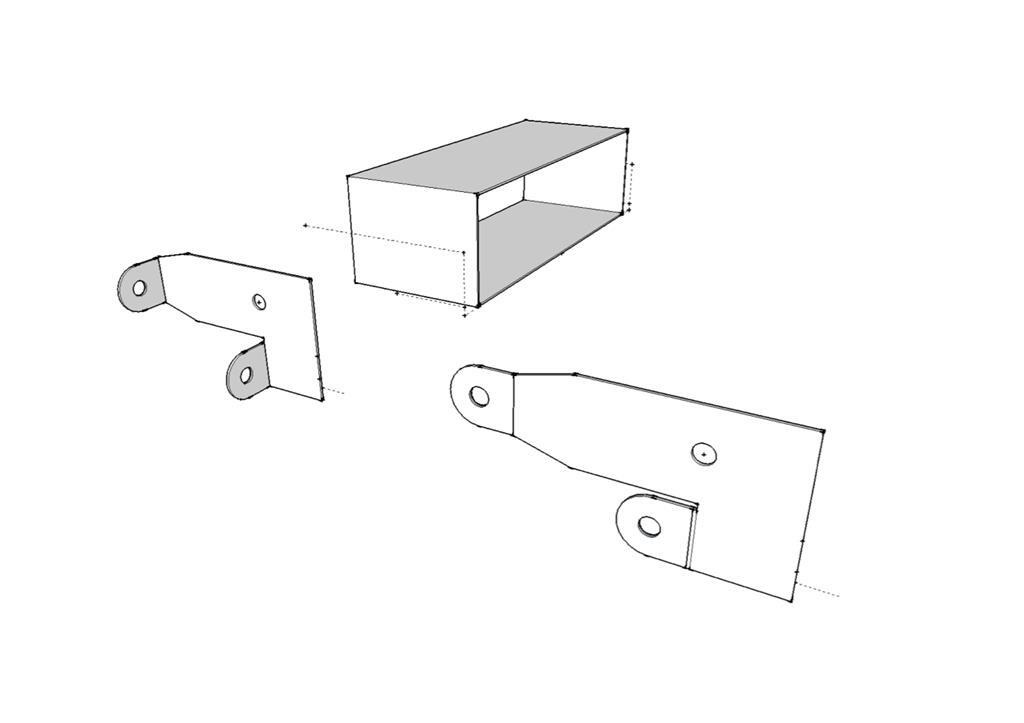

So, effectively they were pressed out of that Zintec stuff. That makes sense. Zinc is a sacrificial coating anyway and there is only a thin layer on the panel so it'll give up sooner or later. Anything modern say post 1980 would be crushed before any significant rust occurred. In Britain anything Japanese built before 1980 dissolved before you could make it to a crusher! Shame really. I'd love a 70s Celica. Anyway, back to the MR2... To recap - I was miffed that the radio was hanging loosely on the bezel and I wanted it bolted in properly, Toyota stylee. That involved remaking the cage for the radio to slide into and making some brackets to bolt it to the dash. So I took some measurements and made a drawing.  That was the recap. Here on it's all new and exciting. Well, new anyway. From the drawing I made a couple of cardboard templates which were bolted to the car…  …and taped to the side of the cage to make sure it all fitted.  Well it was close. Close enough to try it in steel.  The holes in the side allowed me to bolt the brackets to the cage and fit the whole lot to the car. Once everything lined up I could tighten the bolts and carefully remove it for welding.  The radio still fits in my home made cage.  The cage fits in the car.  And the whole lot fits together and works. Cool!  It's not perfect but it'll do. For now. I might tweak it another day. Sorry about the photos in this bit. They aren't brilliant. Mrs Sweetpea pinched the camera for something or another and I had to take them with my phone. Well, I suppose it is her camera. |

| |

Last Edit: Dec 20, 2018 22:19:55 GMT by Sweetpea

|

|

mrtow

Part of things

Posts: 10

|

|

Dec 20, 2015 18:56:55 GMT

|

|

That is utterly fantastic!

This thread is an absolute inspiration anyway, but the precision in the stereo cage and bracketry is brilliant.

Keep up the good work.

|

| |

|

|

I did try and tell them there was a financial benefit if they paid me to stay away but they wouldn't have it. Sadly Mrs Sweetpea has been saving jobs up while I've been messing with the car too. There is a small pile of oak in the back room which needs to box in the landing window. I think that might be tomorrows job.

I did try and tell them there was a financial benefit if they paid me to stay away but they wouldn't have it. Sadly Mrs Sweetpea has been saving jobs up while I've been messing with the car too. There is a small pile of oak in the back room which needs to box in the landing window. I think that might be tomorrows job. I did try and tell them there was a financial benefit if they paid me to stay away but they wouldn't have it. Sadly Mrs Sweetpea has been saving jobs up while I've been messing with the car too. There is a small pile of oak in the back room which needs to box in the landing window. I think that might be tomorrows job.

I did try and tell them there was a financial benefit if they paid me to stay away but they wouldn't have it. Sadly Mrs Sweetpea has been saving jobs up while I've been messing with the car too. There is a small pile of oak in the back room which needs to box in the landing window. I think that might be tomorrows job.