The garage is filling up with stuff, most notably this.

(Don’t get too excited, It’ll be a while before it goes near a another car.)

So I need to get rid of some other stuff that’s cluttering the garage up. That Vitara exhaust silencer for example.

I should explain that grafting a Suzuki silencer onto an MR2 is not a recommended course of action. Especially when you can buy a stainless system that actually fits an MR2 and save the bother. And even more especially when the silencer is no longer on the Suzuki because it had a hole in it. But it was an itch I had to scratch and I scratched it.

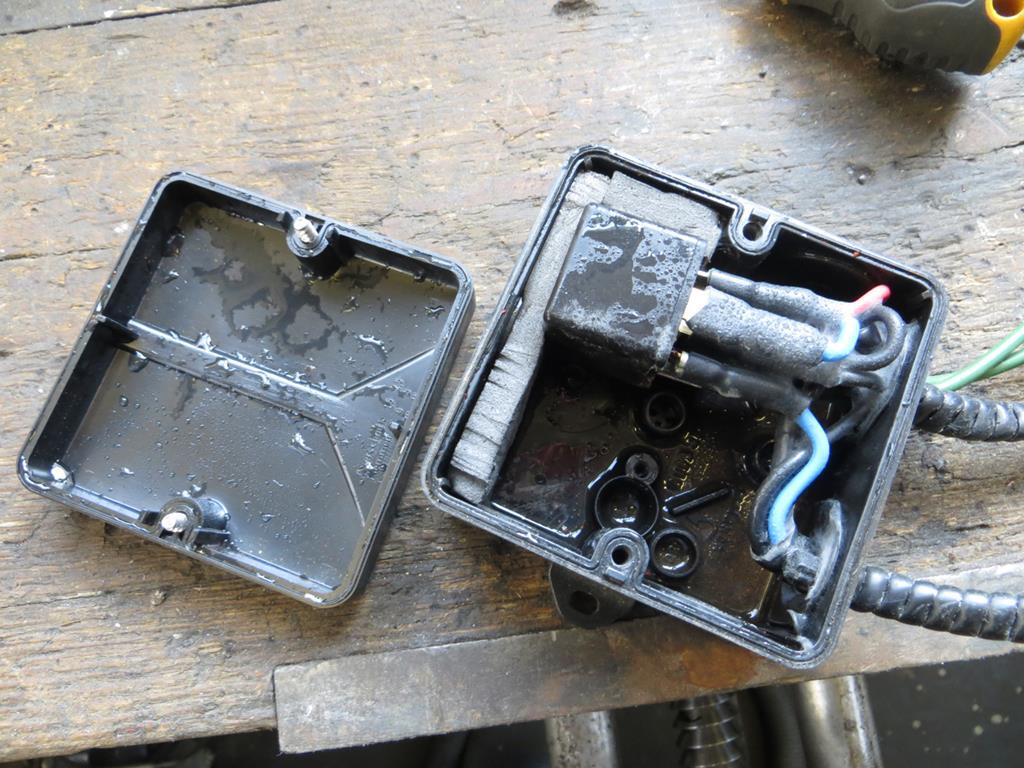

I’d already repaired the hole and made new hangers from stainless threaded rod. Next I need a flange for the inlet pipe. So I dug around in the scrap bin and found a bit of plate.

A bit of forming got me the shape and then I had the task of making the hole in the middle. I did this by chain drilling using the pillar drill and then using the power file to get to the right size.

Here we are. The bit of pipe I happen to have seems to fit in the hole.

Now, the piece of pipe is, er, part of a steel bed head.

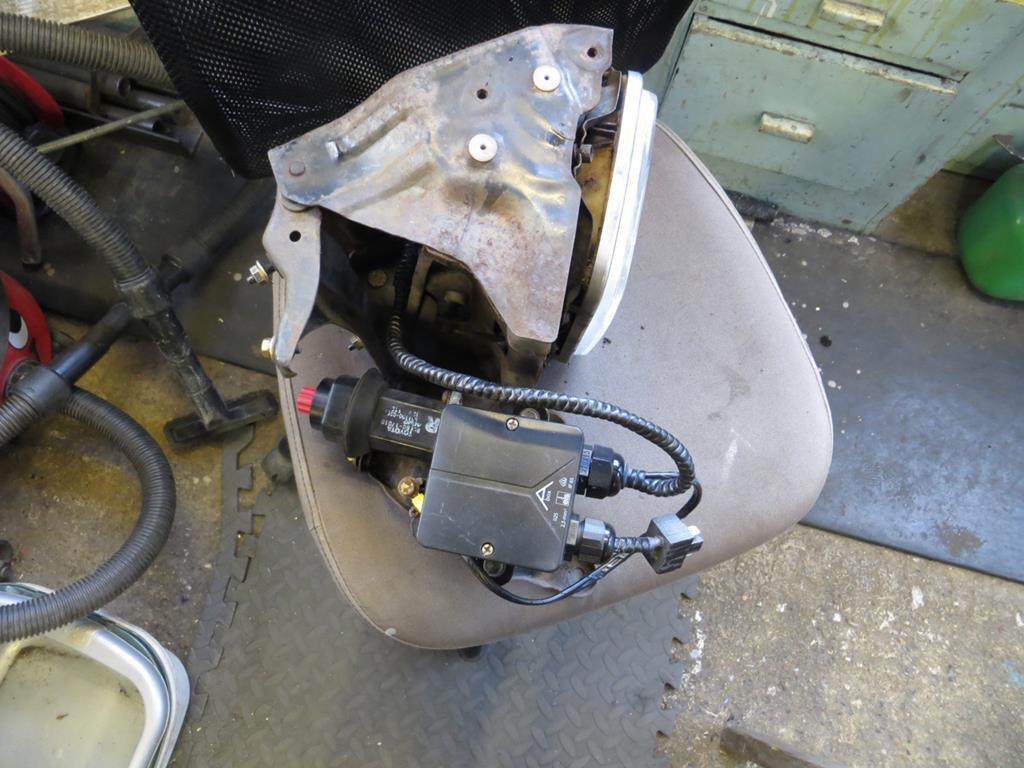

Next I cut the down pipe off just after the Flexi section and mulled over the job of connecting the ends together.

Looks promising from this angle. From the back we see that there is a bit of an offset to deal with.

But it’s not too terrible.

Another rummage in the scrap bin and I tracked down a piece of pipe that was exactly the right size and shape.

I’m genuinely astonished that I just happened to have this lying around but it’s the honest truth. Honestly. Would I tell you a fib?

See! I told you it was a perfect fit. Next I needed to weld it up with the TIG.

But I don’t own a TIG so I had to use the MIG instead. Not the tidiest welding I’ve ever done but it’s functional.

I need to remember that I need to concentrate and not just buzz things together. I’m much better when I concentrate.

The last little job was to reposition the tail pipe which was both too long and too far to the drivers side.

See, I paid more attention to that weld and did a better job.

So now we have this…

Which looks like this from the back.

Which isn’t too shabby.

I think I’ve probably got a few pin holes to find and weld up. And where my new pipe connects to the silencer I need a 2 inch fibre exhaust gasket. At the moment is bunged up with lots of paste but that won’t stay in one piece for long.

So, what’s it sound like, and is it worth you all following in my footsteps?

Well, the old box was blowing. And it had a horrible resonance that rattled the the ornaments off the mantlepiece in the living room.

The new one has a low burbly tone, I think due to it being 2 inches in diameter. Most of the resonance has gone too. And I think it’s slightly quieter when burbling around the town. So that’s all good.

When you boot it you get a more pleasing and consistent noise through the rev range. And it’s not short of grunt either.

The bad news is that it’s not what you’d call quiet. Especially when you get to motorway speeds where it might be noisier than it was before. On the Vitara there was a cat and resonator early on in the system which would knock a lot of the noise out. The MR2 has neither now, it’s all down to the rear box. I could, possibly, have got the MR2’s first box in but the packaging would have been ‘interesting’ and it’d defeat the idea of having a centre entry to the rear box.

Anywhooo. I’ll get a gasket, spend a little time finding any pin holes and live with it for a while. Then I’ll decide if it stays or goes. The pipe is only mild steel and is very thin walled so it’ll probably not last long anyway.

Should you do it too? Probably not. Just buy one. Like I said, it was an itch I needed to scratch.

Got to go to work in Ye Old London Town tomorrow so I’ll probably be dead by lunchtime… Wish me luck.

James

(Don’t get too excited, It’ll be a while before it goes near a another car.)

So I need to get rid of some other stuff that’s cluttering the garage up. That Vitara exhaust silencer for example.

I should explain that grafting a Suzuki silencer onto an MR2 is not a recommended course of action. Especially when you can buy a stainless system that actually fits an MR2 and save the bother. And even more especially when the silencer is no longer on the Suzuki because it had a hole in it. But it was an itch I had to scratch and I scratched it.

I’d already repaired the hole and made new hangers from stainless threaded rod. Next I need a flange for the inlet pipe. So I dug around in the scrap bin and found a bit of plate.

A bit of forming got me the shape and then I had the task of making the hole in the middle. I did this by chain drilling using the pillar drill and then using the power file to get to the right size.

Here we are. The bit of pipe I happen to have seems to fit in the hole.

Now, the piece of pipe is, er, part of a steel bed head.

Next I cut the down pipe off just after the Flexi section and mulled over the job of connecting the ends together.

Looks promising from this angle. From the back we see that there is a bit of an offset to deal with.

But it’s not too terrible.

Another rummage in the scrap bin and I tracked down a piece of pipe that was exactly the right size and shape.

I’m genuinely astonished that I just happened to have this lying around but it’s the honest truth. Honestly. Would I tell you a fib?

See! I told you it was a perfect fit. Next I needed to weld it up with the TIG.

But I don’t own a TIG so I had to use the MIG instead. Not the tidiest welding I’ve ever done but it’s functional.

I need to remember that I need to concentrate and not just buzz things together. I’m much better when I concentrate.

The last little job was to reposition the tail pipe which was both too long and too far to the drivers side.

See, I paid more attention to that weld and did a better job.

So now we have this…

Which looks like this from the back.

Which isn’t too shabby.

I think I’ve probably got a few pin holes to find and weld up. And where my new pipe connects to the silencer I need a 2 inch fibre exhaust gasket. At the moment is bunged up with lots of paste but that won’t stay in one piece for long.

So, what’s it sound like, and is it worth you all following in my footsteps?

Well, the old box was blowing. And it had a horrible resonance that rattled the the ornaments off the mantlepiece in the living room.

The new one has a low burbly tone, I think due to it being 2 inches in diameter. Most of the resonance has gone too. And I think it’s slightly quieter when burbling around the town. So that’s all good.

When you boot it you get a more pleasing and consistent noise through the rev range. And it’s not short of grunt either.

The bad news is that it’s not what you’d call quiet. Especially when you get to motorway speeds where it might be noisier than it was before. On the Vitara there was a cat and resonator early on in the system which would knock a lot of the noise out. The MR2 has neither now, it’s all down to the rear box. I could, possibly, have got the MR2’s first box in but the packaging would have been ‘interesting’ and it’d defeat the idea of having a centre entry to the rear box.

Anywhooo. I’ll get a gasket, spend a little time finding any pin holes and live with it for a while. Then I’ll decide if it stays or goes. The pipe is only mild steel and is very thin walled so it’ll probably not last long anyway.

Should you do it too? Probably not. Just buy one. Like I said, it was an itch I needed to scratch.

Got to go to work in Ye Old London Town tomorrow so I’ll probably be dead by lunchtime… Wish me luck.

James