jonomisfit

Club Retro Rides Member

Posts: 1,787

Club RR Member Number: 49

|

|

Jan 31, 2016 16:55:09 GMT

|

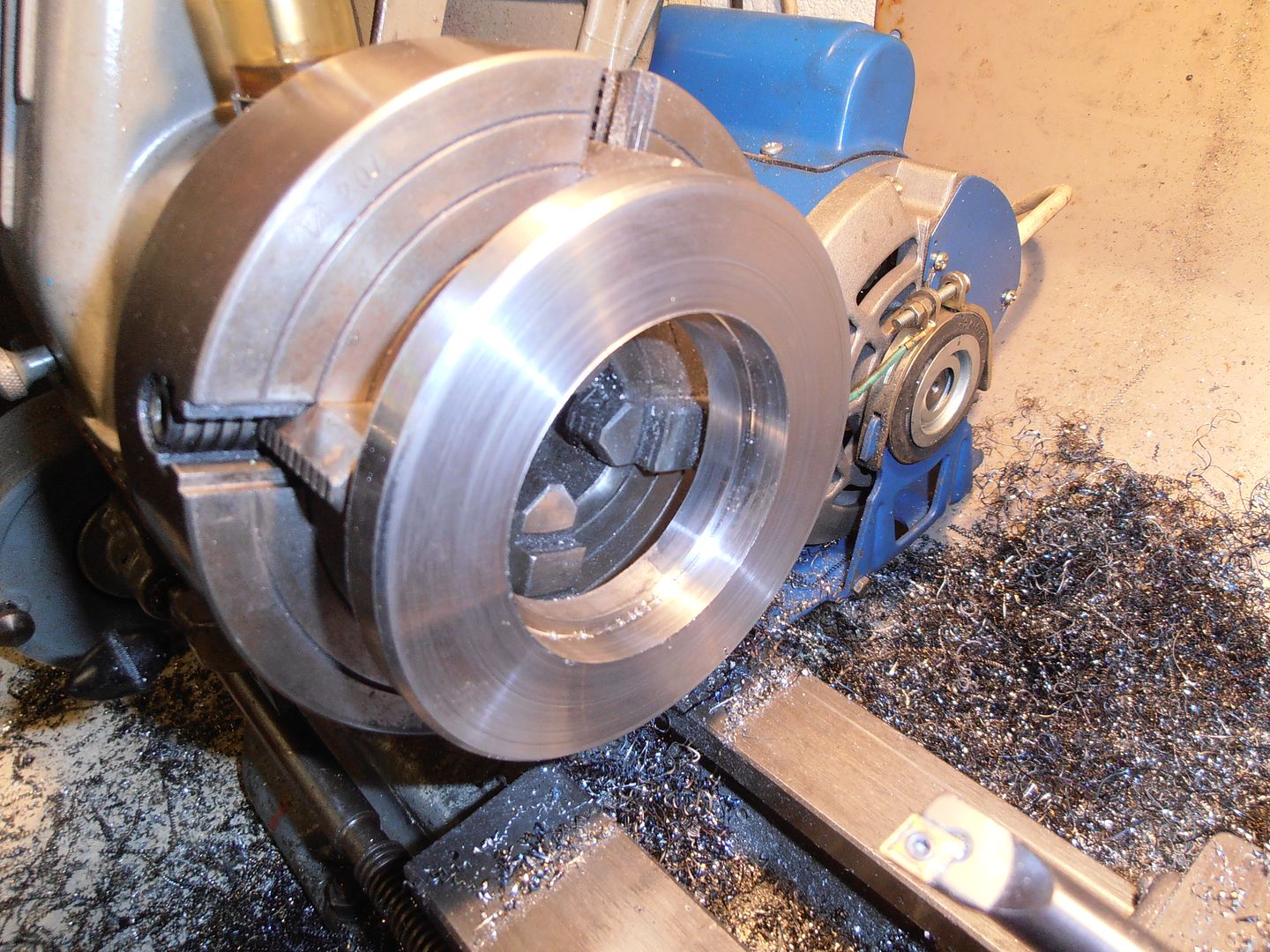

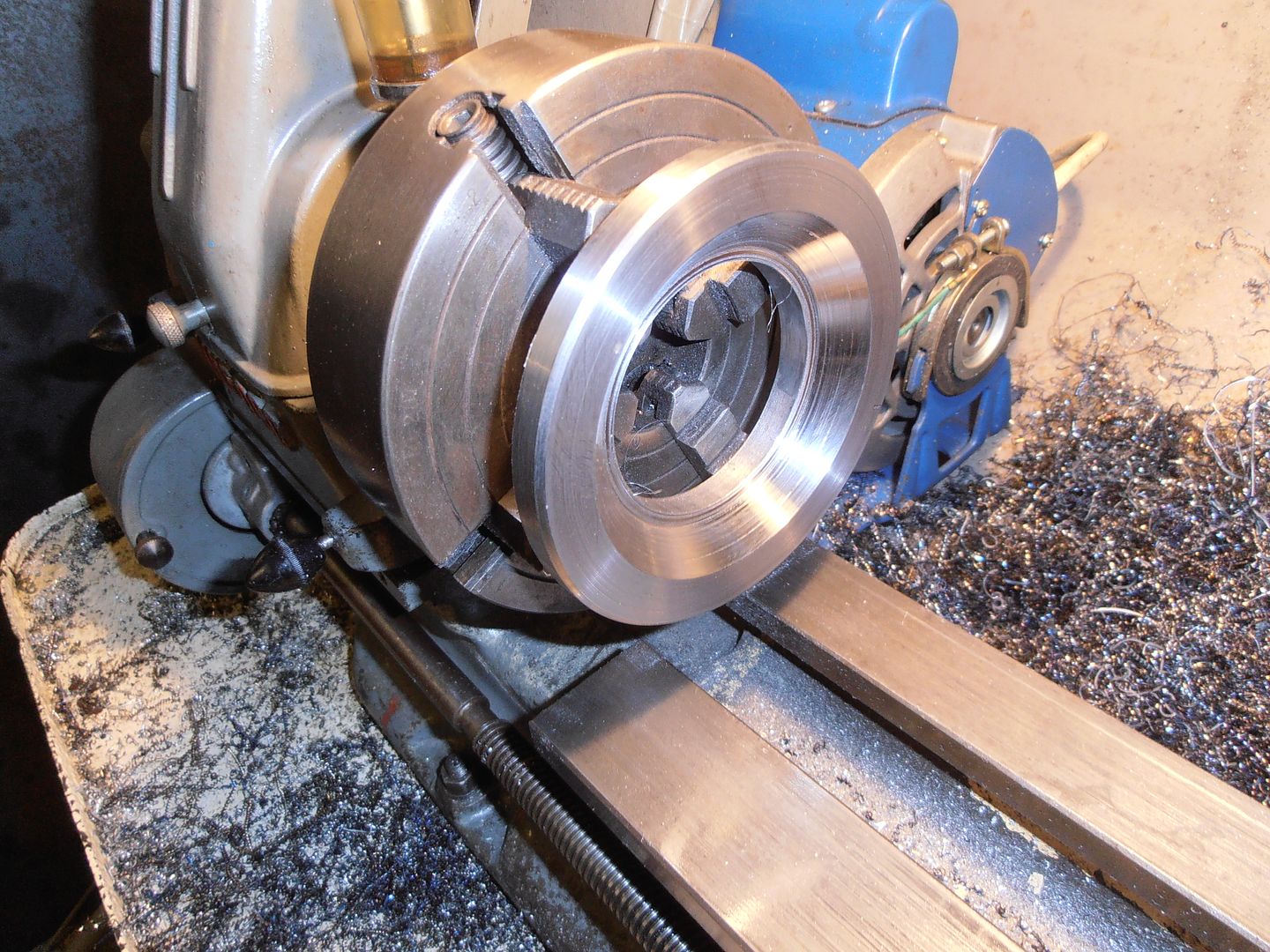

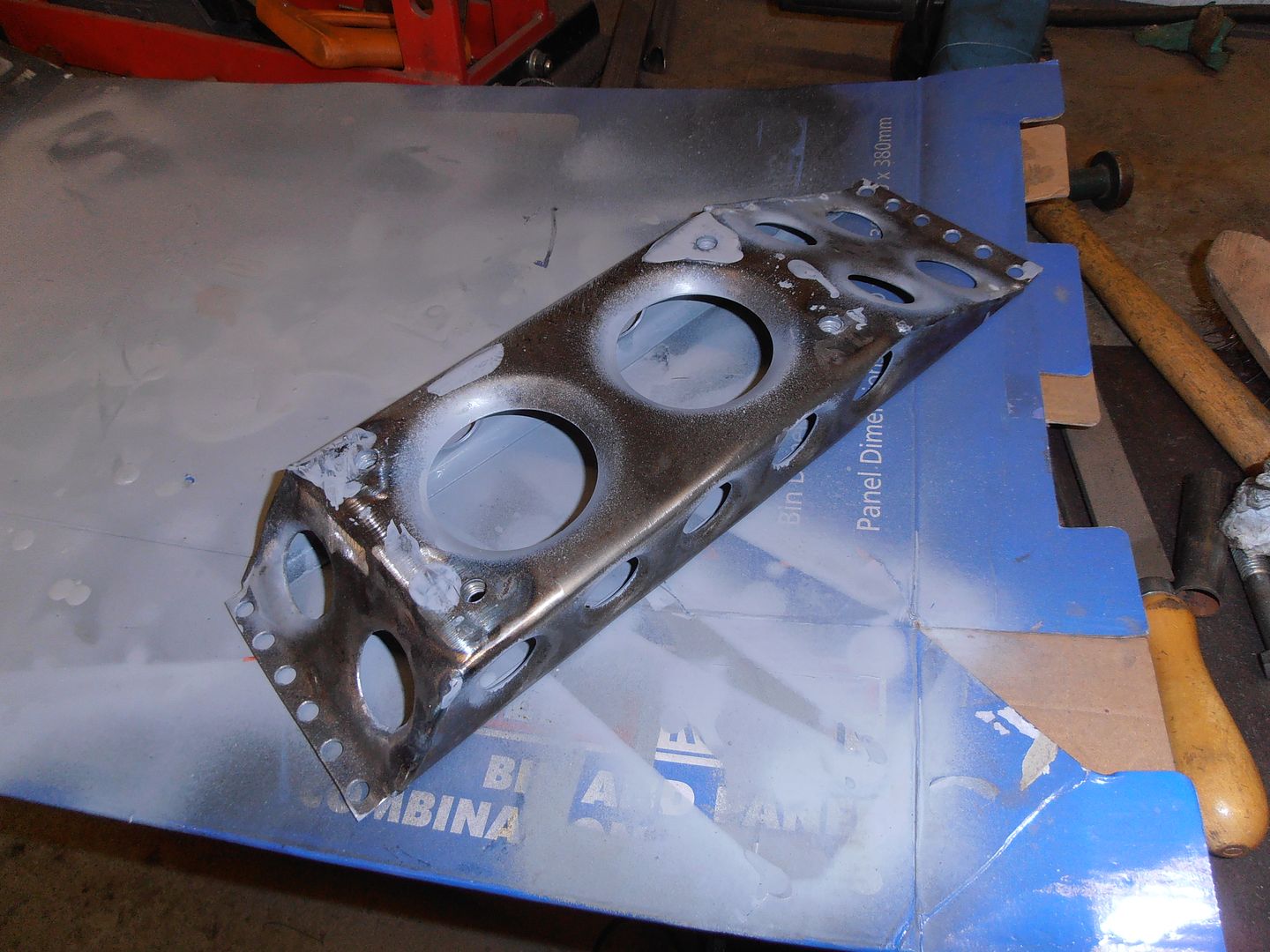

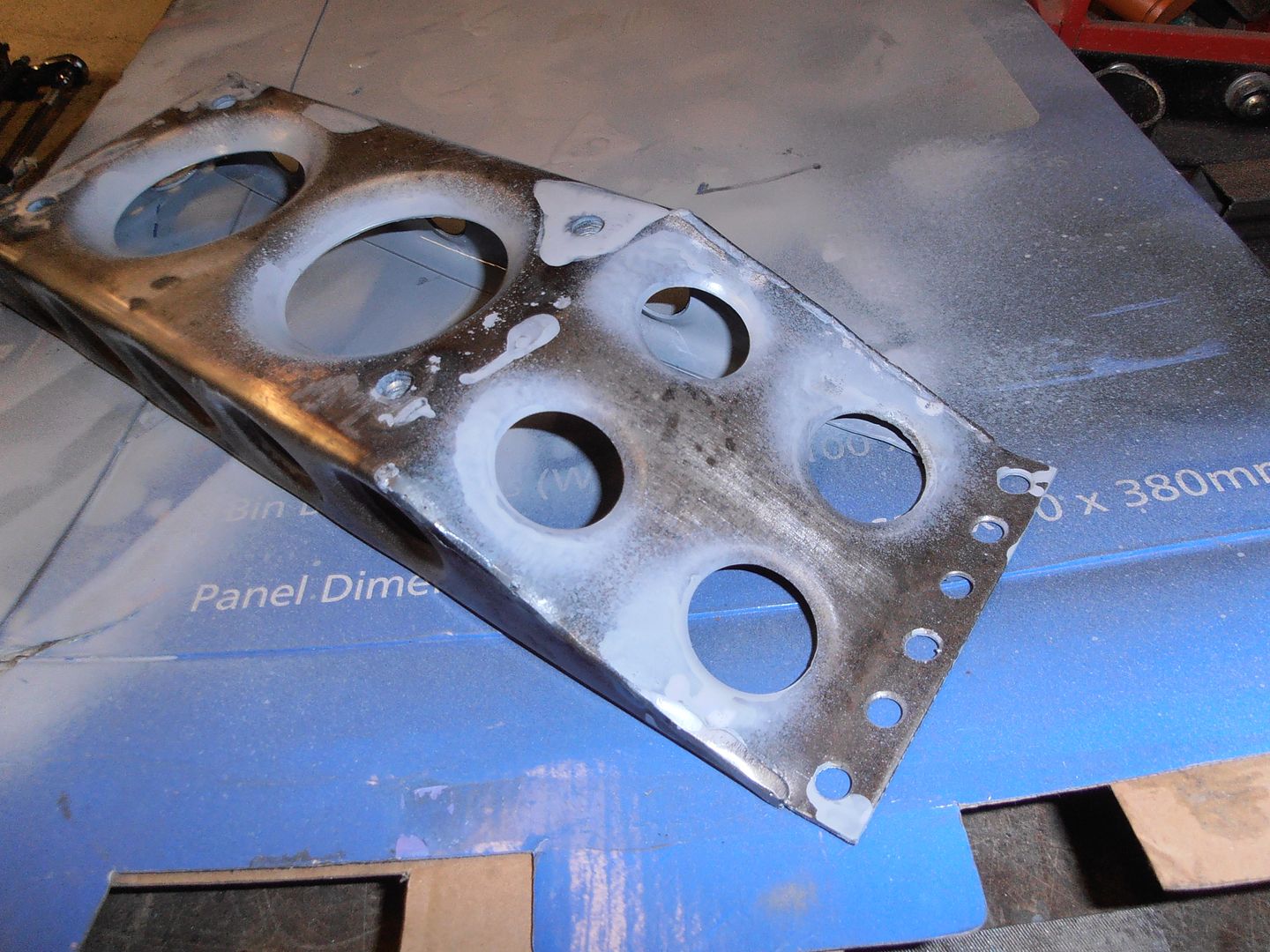

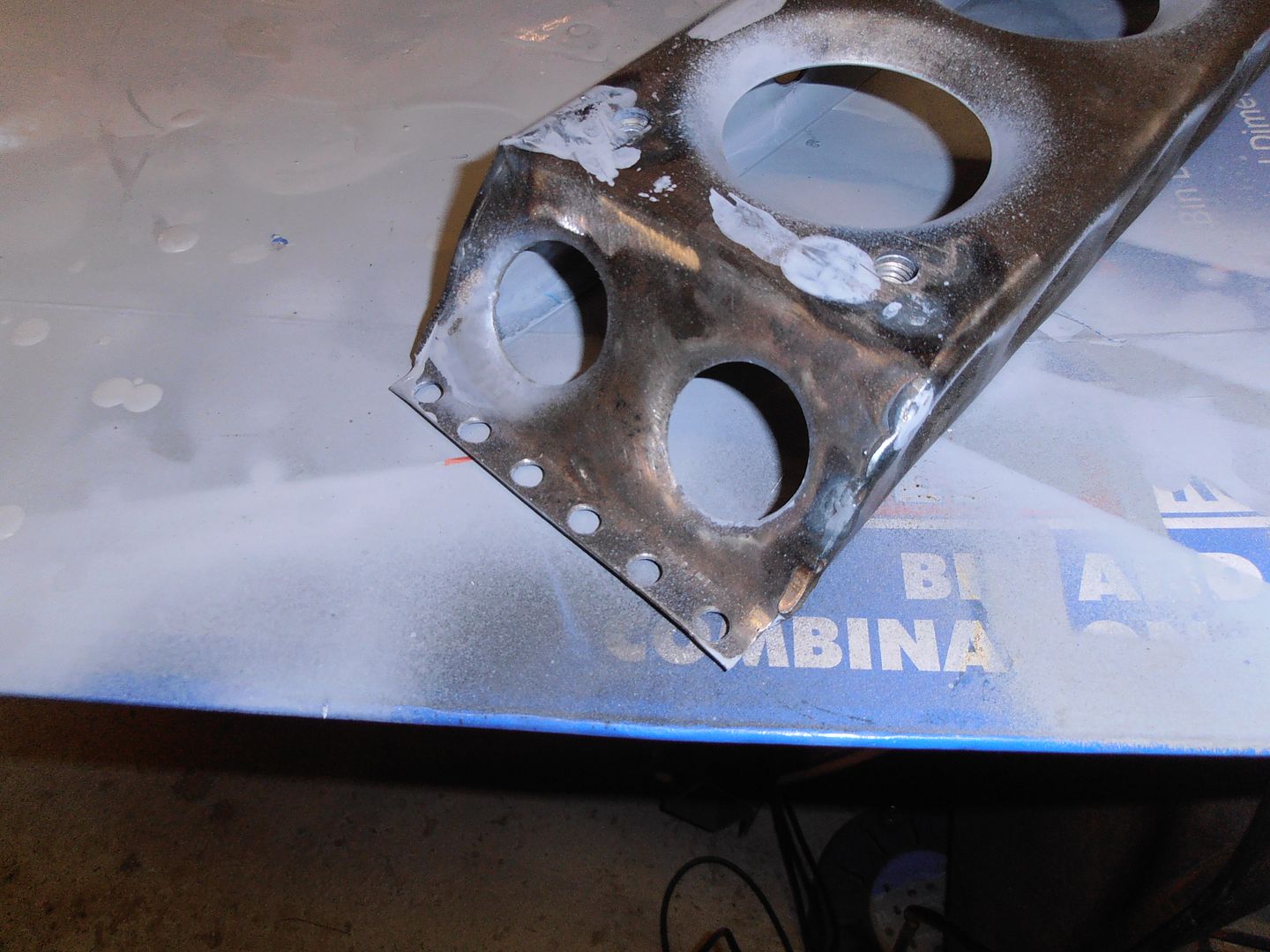

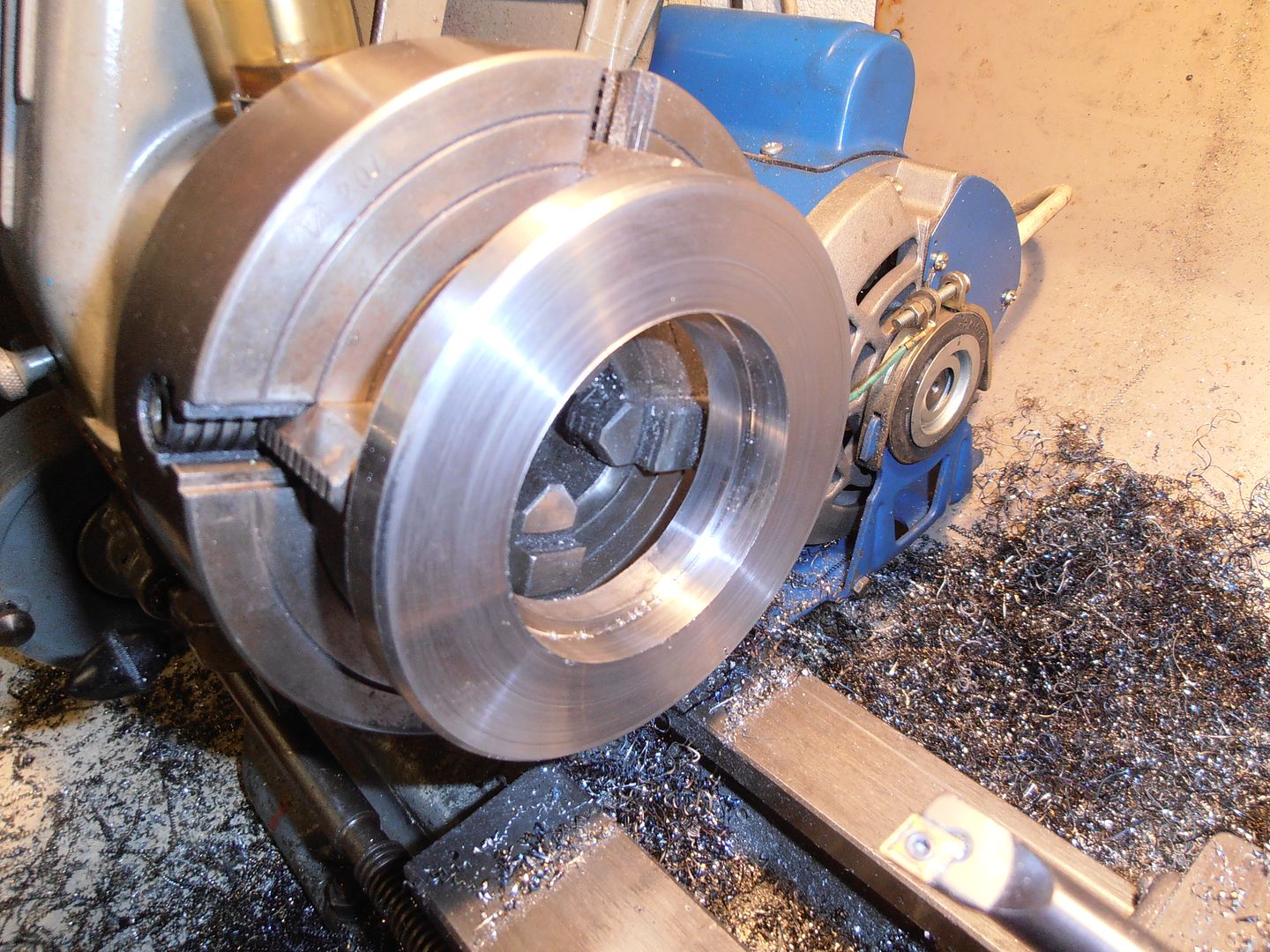

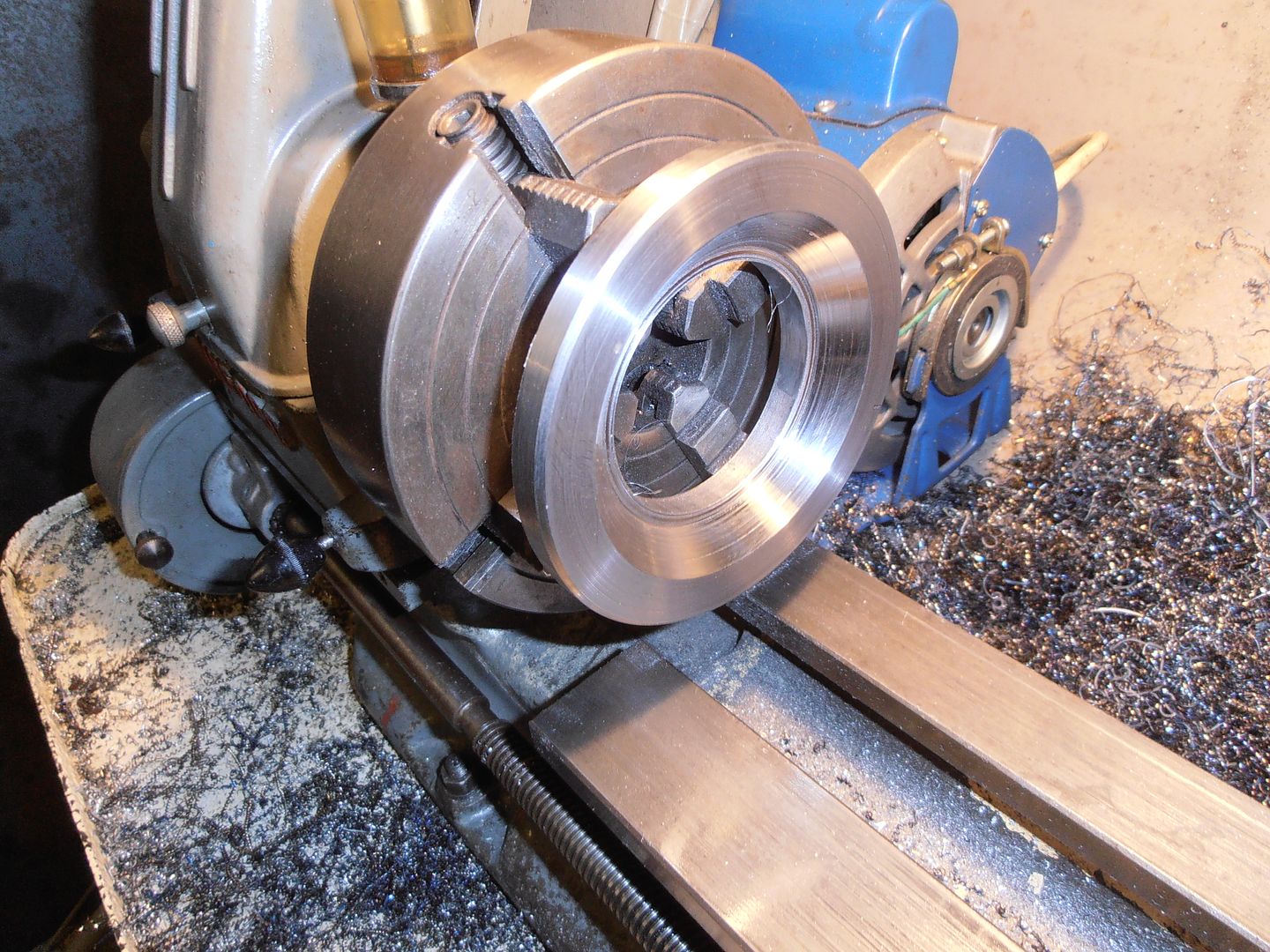

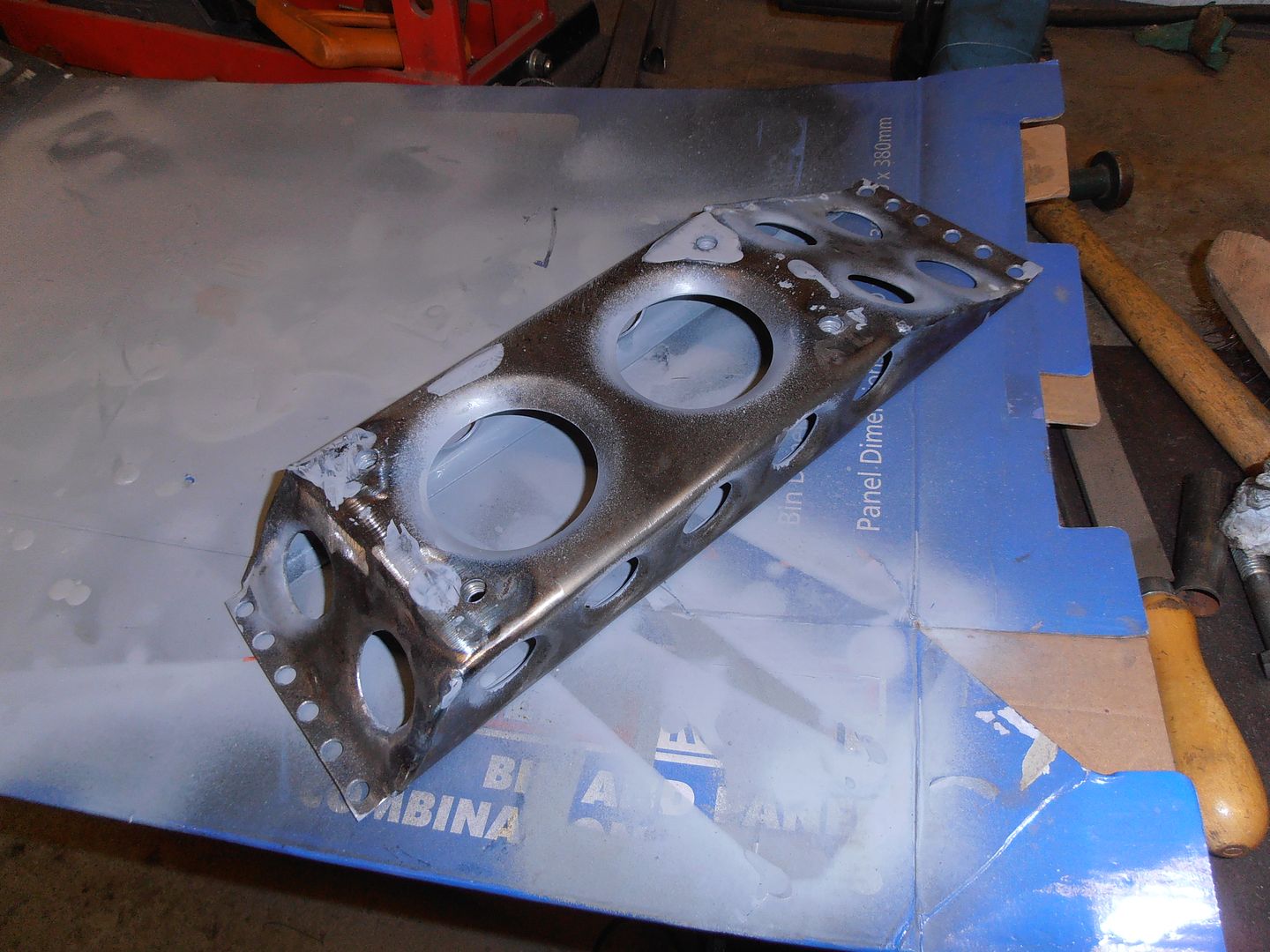

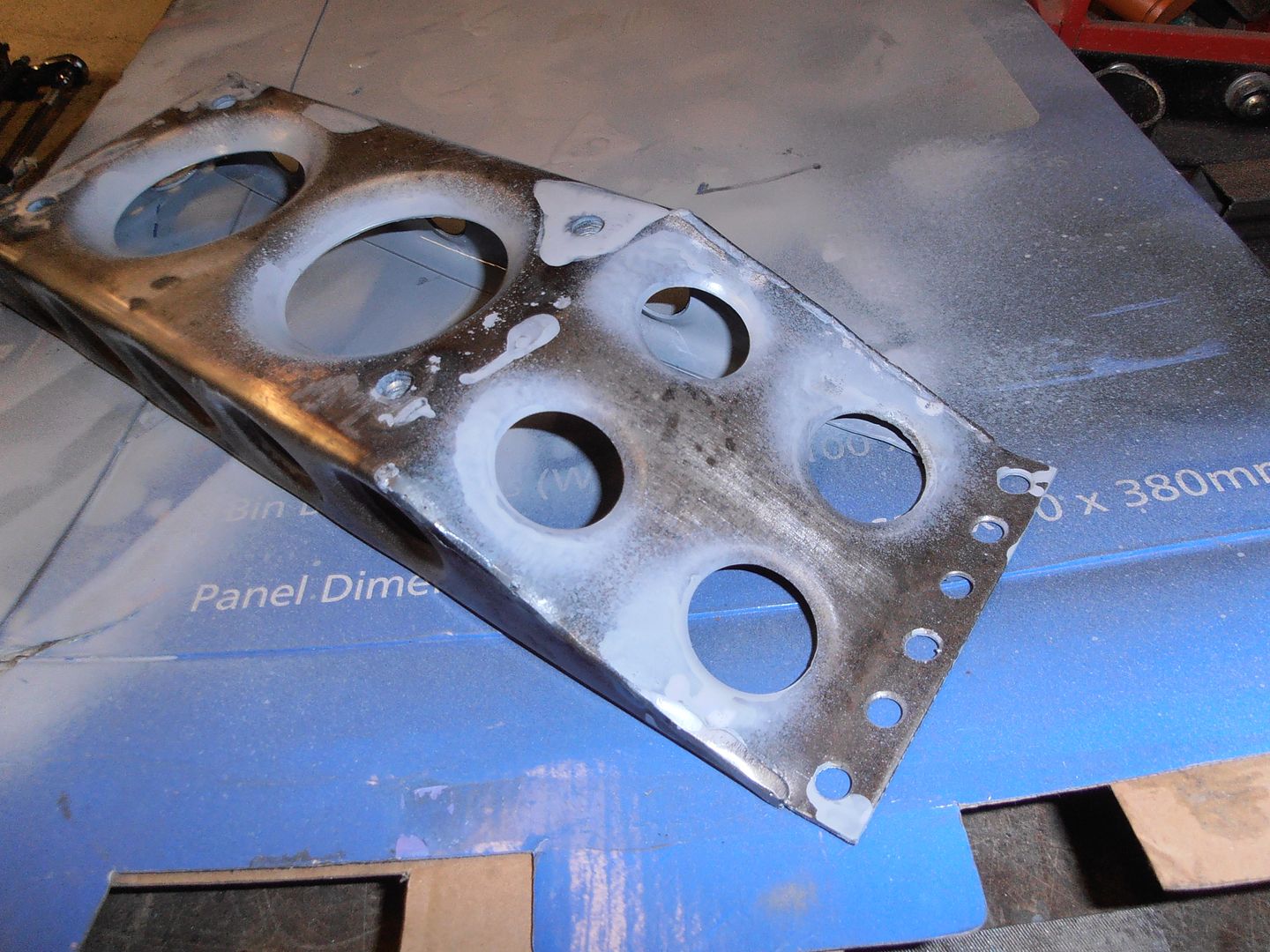

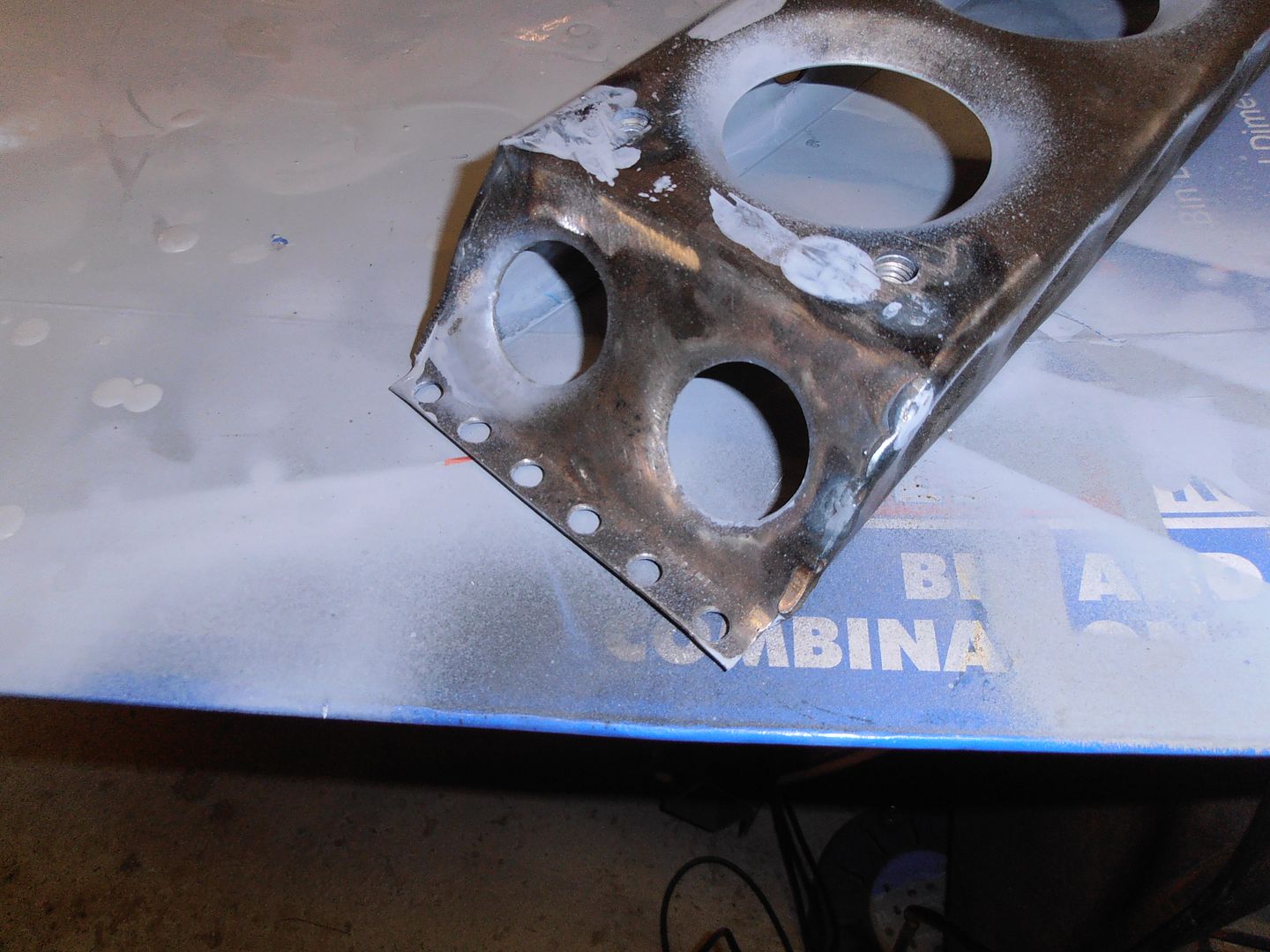

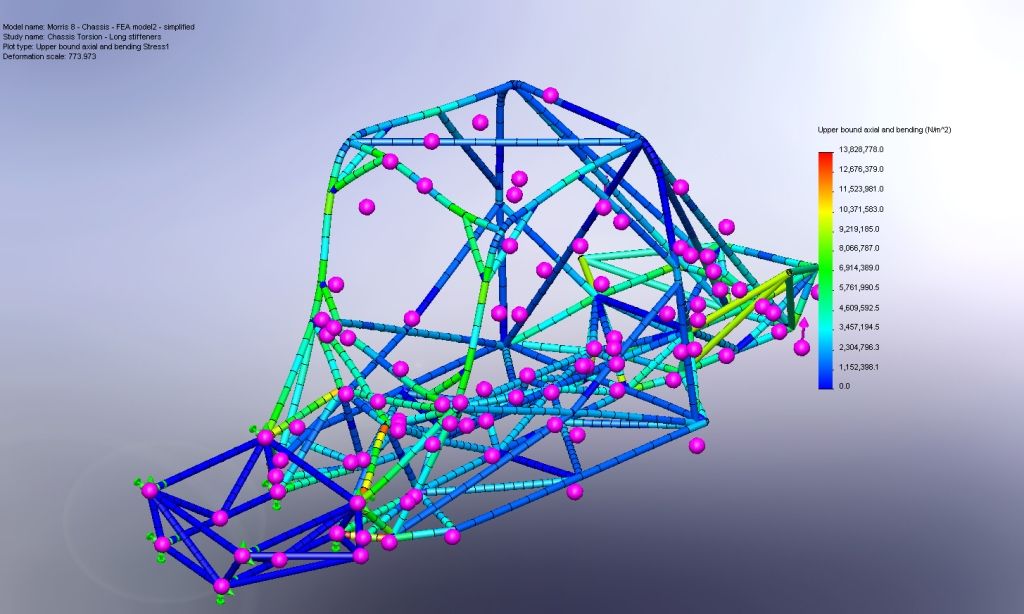

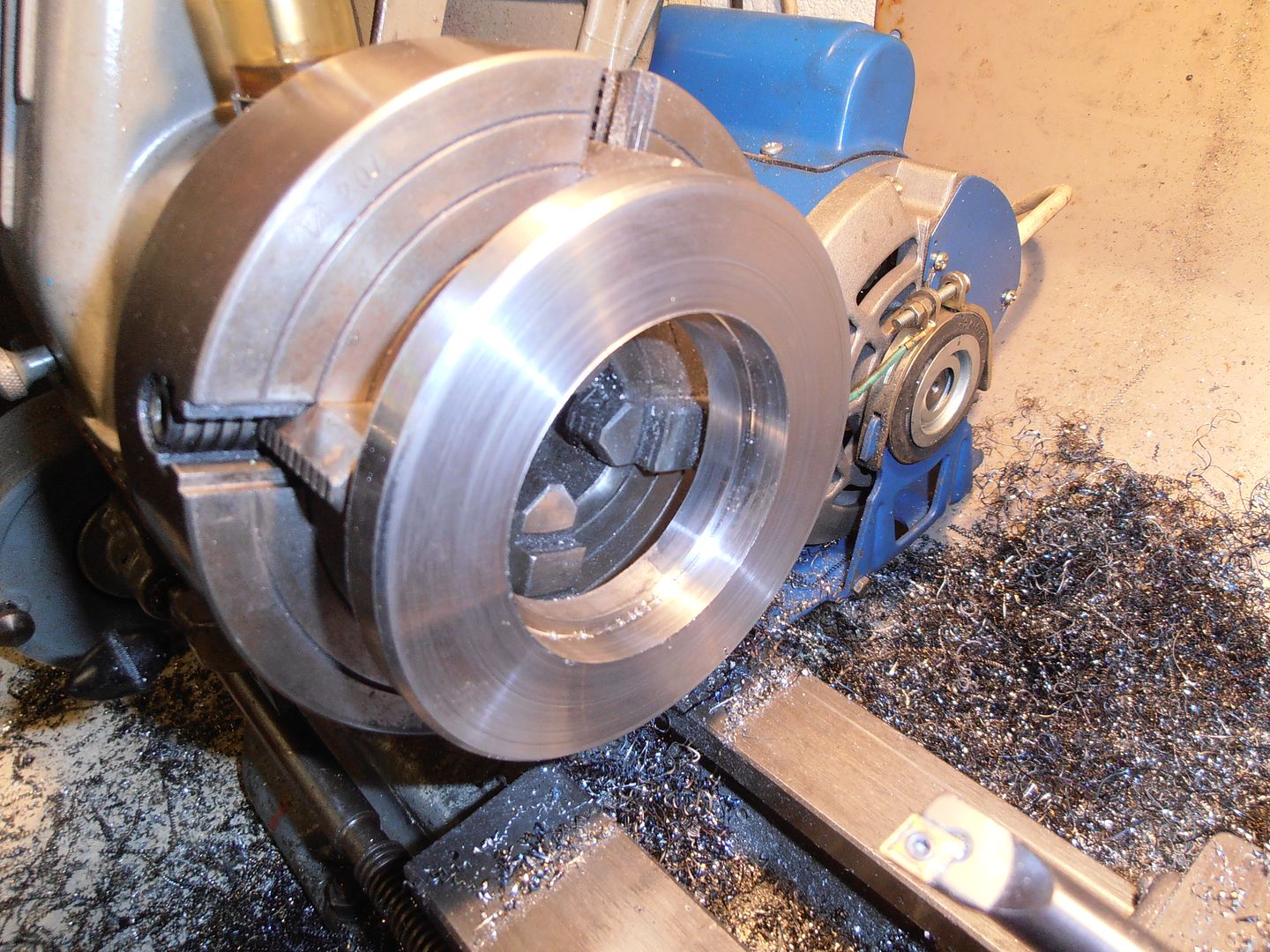

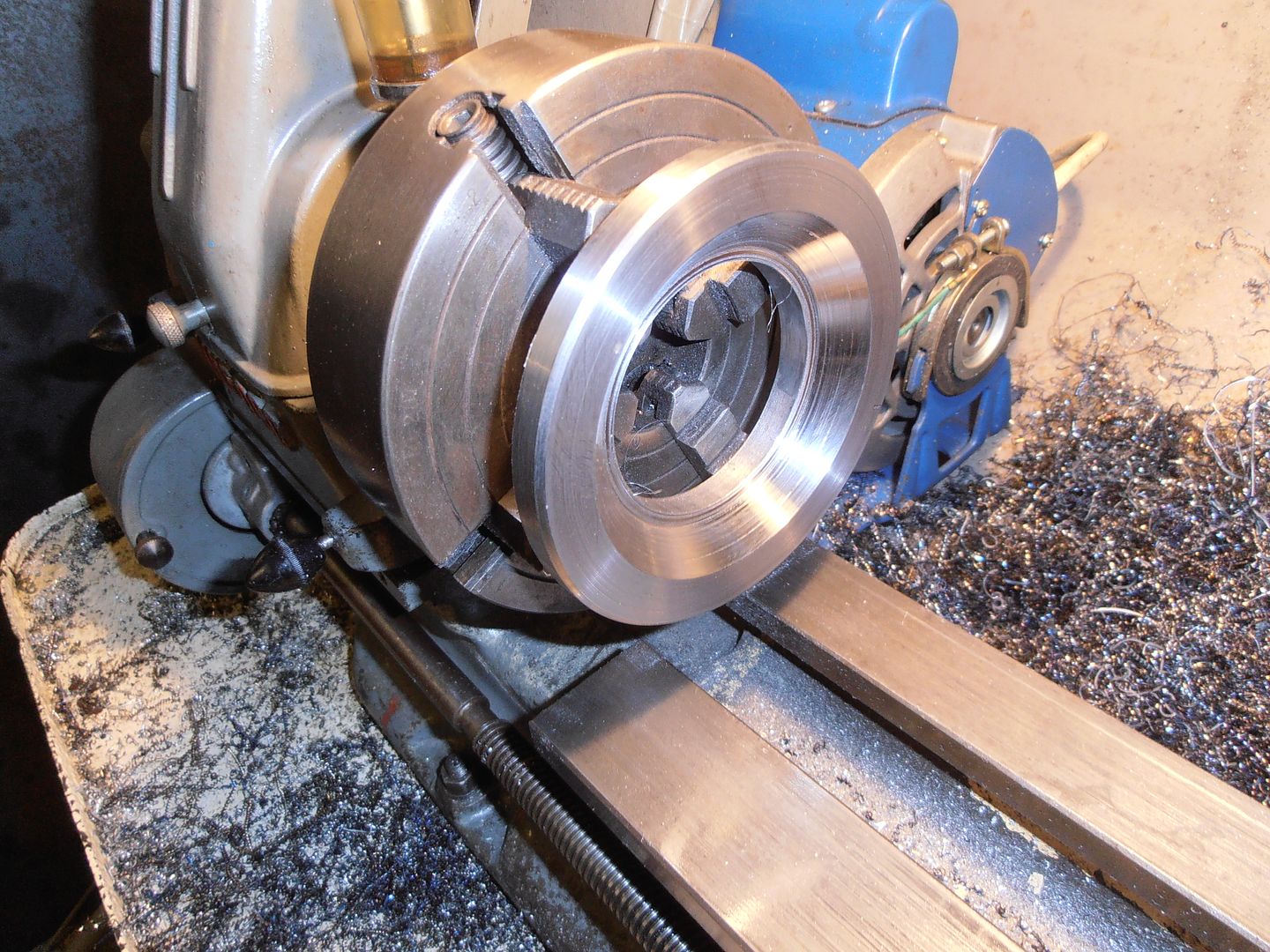

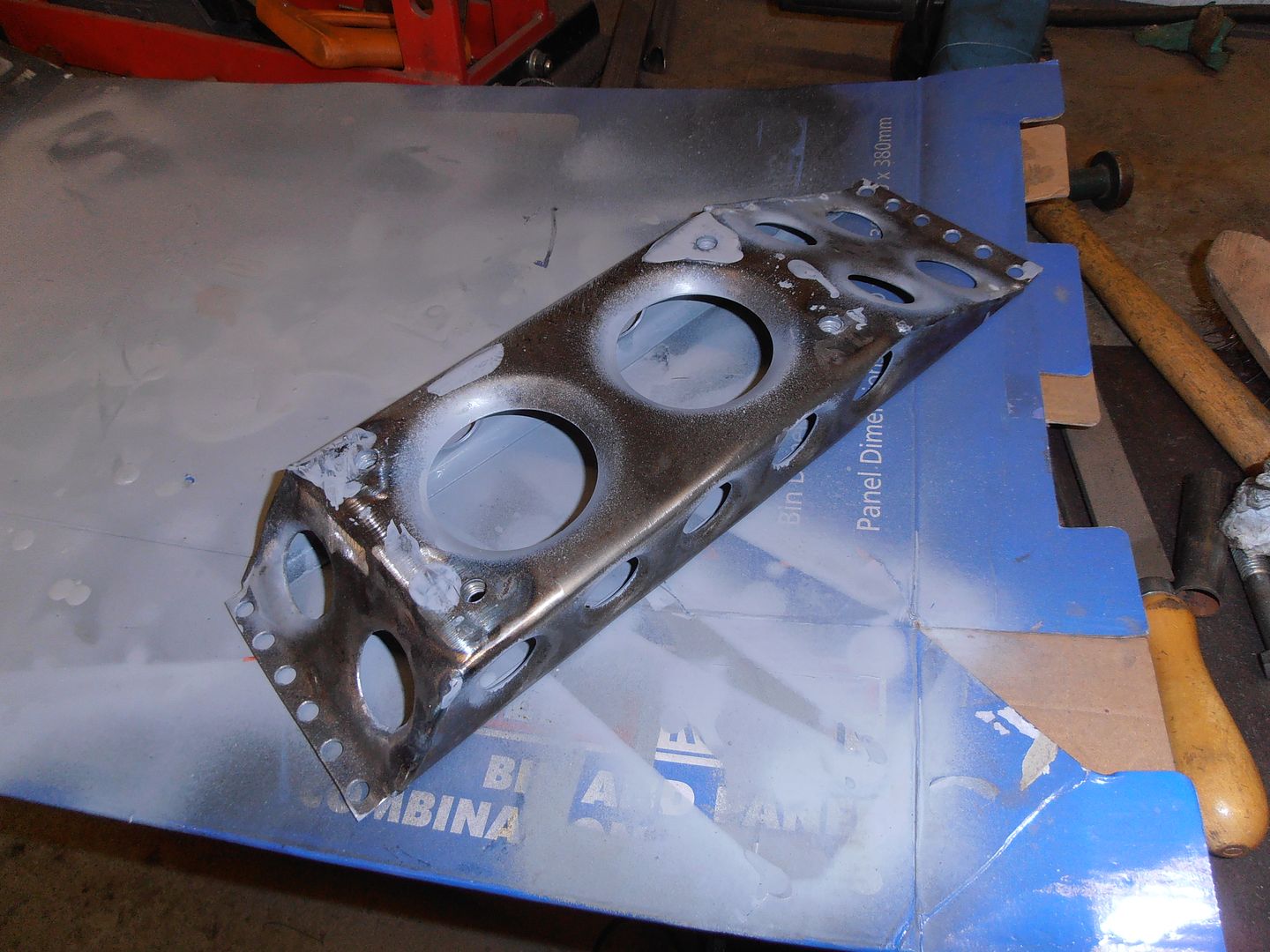

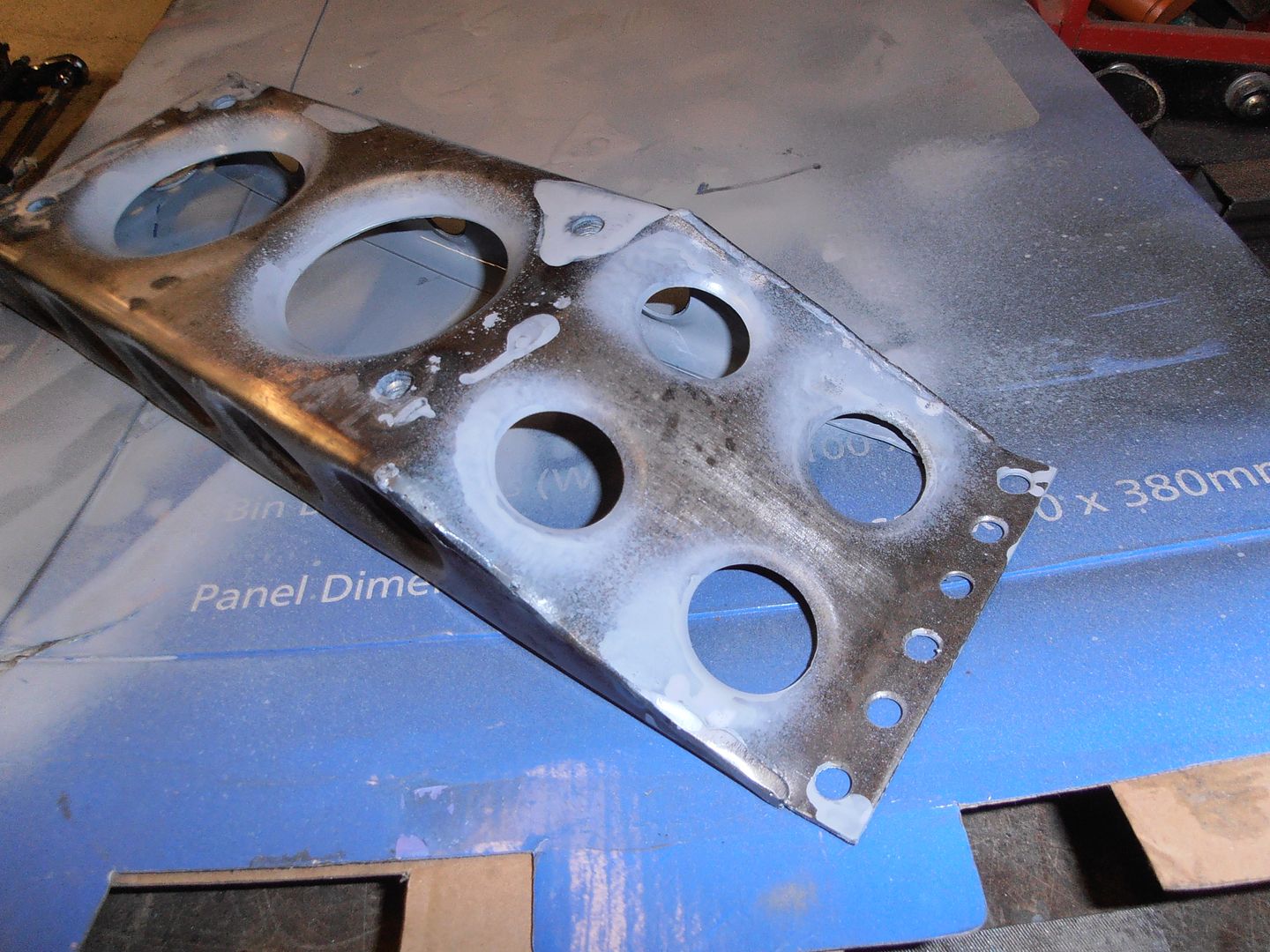

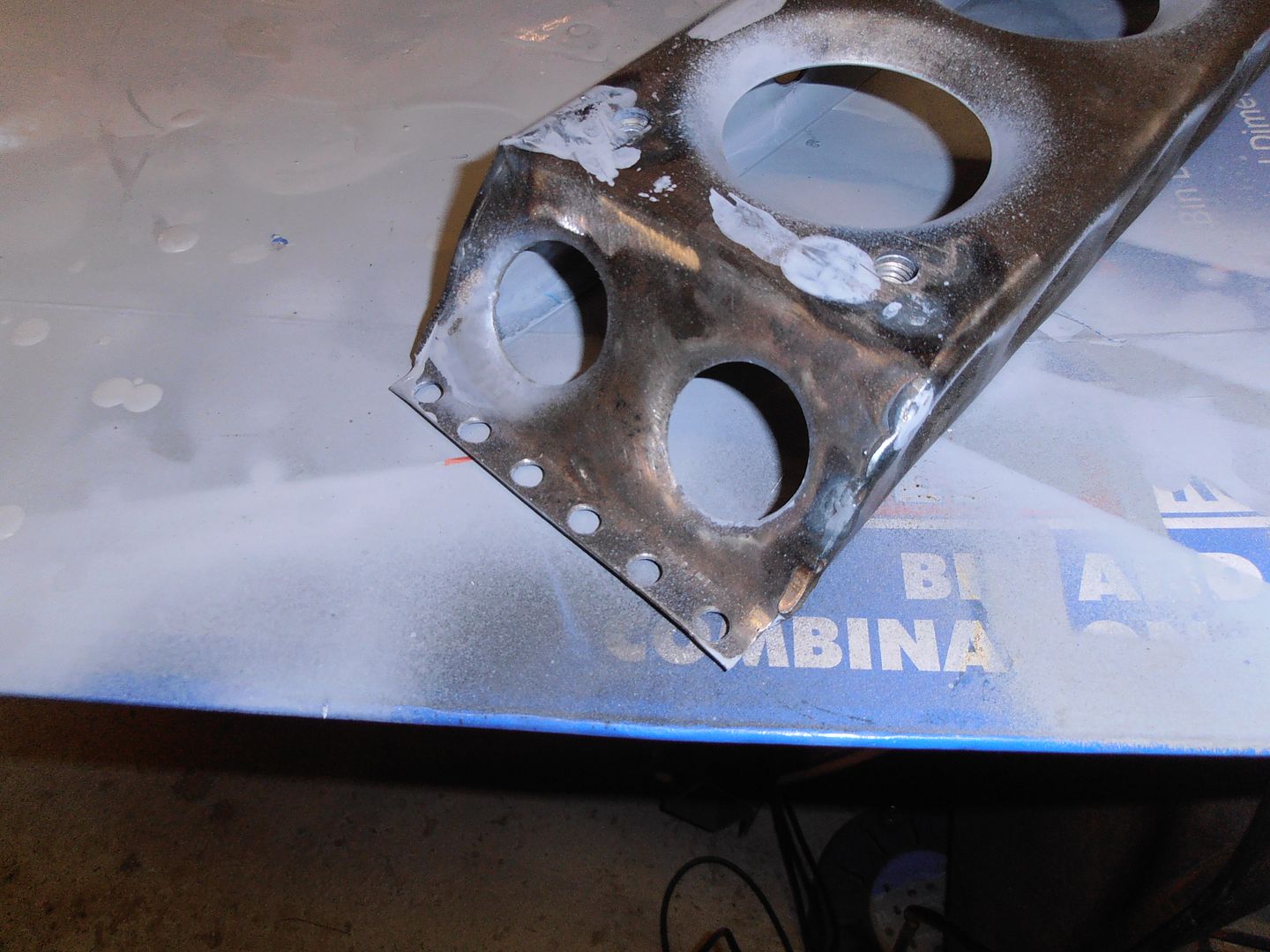

Finished the chain drilling on the second part and cut the piece out with the hole saw  Centered it in the lathe (managed to get to 0.03mm run out, just over a thou in old money, which is much better than trying to get it centered in the 3 jaw chuck which is about 0.3mm out!) Because the lathe is only 3 speed, and there was some flex on things, it was chattering when taking cuts. with a 64mm hole in the center I needed to use an adaptor to center it. A hand old motor pulley did the trick.  turned it down to the right OD... eventually. The used the boring bar to cut the internal. This is the first time i've really tried boring anything so too a while to get it all set and cut. Bored it to the correct size interior step first,   then cut the 45deg taper. came out nicely.  Did a fit up trial with the male half. Decided it could do with a little longer center guide on the male piece, so used the section I cut out from the female part, tapped it, drilled it so the cap head bolts fitted inside and then put it on.    Now to try it in the press. Tenter hooks in case I ballsed up the bracket.  Well i'll be. Worked nicely, really nicely. Took out some of the ripple in the surface as well.   the setup  After the amount of time it took to make, i'll have to make a lot of parts with 64mm swaged holes in then to justify the effort! made some more swage tools and swaged the remaining holes    before I can fit the rack I need to make a couple of spacer blocks to get it to the correct height. I need to order the material. Not certain when i'll be back on the car, plus also need to design a few more bits. |

| |

|

|

|

|

mk2cossie

Club Retro Rides Member

Posts: 3,054  Club RR Member Number: 77

Club RR Member Number: 77

|

|

Jan 31, 2016 18:42:51 GMT

|

With the track rod ends, would it not have been simpler to have just made a taper on the opposite side of the arm on the hub?  Loving the build otherwise though, and the extension use of additional gussets  |

| |

|

|

jonomisfit

Club Retro Rides Member

Posts: 1,787

Club RR Member Number: 49

|

|

Jan 31, 2016 20:03:09 GMT

|

|

Thanks. Always like feedback.

Not 100% sure i follow you though mk2cossie.

Do you mean re-cut the track rod taper to the top of the steering arm on the upright? i.e. taper from top face to bottom face.

or

Do you mean put the rod end under the steering arm in the same way the way the original track rod end was mounted? Unfortunately if I mount it this way the rack position comes out in the middle of the wishbone / chassis, which why I had to re-locate to above the steering arm.

I do like a good gusset :-)

|

| |

|

|

mk2cossie

Club Retro Rides Member

Posts: 3,054  Club RR Member Number: 77

Club RR Member Number: 77

|

|

Jan 31, 2016 21:30:03 GMT

|

Thanks. Always like feedback. Not 100% sure i follow you though mk2cossie. Do you mean re-cut the track rod taper to the top of the steering arm on the upright? i.e. taper from top face to bottom face. or Do you mean put the rod end under the steering arm in the same way the way the original track rod end was mounted? Unfortunately if I mount it this way the rack position comes out in the middle of the wishbone / chassis, which why I had to re-locate to above the steering arm. I do like a good gusset :-) I meant retapering the arm from the top so the track rod end was above with the locking nut on the bottom  Was purely thinking that the original track rod end ball joints have a lot more articulation than the spherical bearings you have on there, and possibly slightly lower profile  |

| |

|

|

jonomisfit

Club Retro Rides Member

Posts: 1,787

Club RR Member Number: 49

|

|

|

|

|

I'd though about recutting the taper to the other side. Unfortunately due to the existing taper I'd have had to cut it oversized and find a different track rod end.

In itself not an insurmountable issue but I decided the rod end solution would be easier. Machining wouldn't be that easy either.

These are fairly standard rod ends. My next move will be high misalignment ones.

|

| |

|

|

fer4l

Posted a lot

Testing

Testing

Posts: 1,497

Club RR Member Number: 73

|

|

|

|

Loving the swage tool - very muchly!  Cheers Matt |

| |

|

|

|

|

|

|

|

On beetles we drill out the taper for the track rod and press a bush into the arm with a new taper from the top. you can buy the bushes. Anti bump steer kits  |

| |

|

|

jonomisfit

Club Retro Rides Member

Posts: 1,787

Club RR Member Number: 49

|

|

|

|

|

Vw. Any links to where you get these from?

That could be a very very handy answer.

|

| |

|

|

|

|

omega

Posted a lot

Posts: 1,060

|

|

|

|

we all have diffrent skills |

| |

|

|

|

|

jonomisfit

Club Retro Rides Member

Posts: 1,787

Club RR Member Number: 49

|

|

|

|

|

:-( I may have been lazy as on phone.

Thanks though, appreciated

|

| |

|

|

bstardchild

Club Retro Rides Member

Posts: 14,962

Club RR Member Number: 71

|

|

|

|

You've probably already got the answer but - I'm working my way through the thread having only seen it for the first time today it's normally file name length or too many directories - it will work on other forums but not proboard ones  |

| |

|

|

|

|

|

|

|

:-( I may have been lazy as on phone. Thanks though, appreciated My phone is my only internet. I'm only messin  |

| |

|

|

Dez

Club Retro Rides Member

And I won't sit down. And I won't shut up. And most of all I will not grow up.

Posts: 11,790

Club RR Member Number: 34

|

|

|

|

|

theres no reason you cant reverse cut the taper in the steering arms, so they're 'half and half' and the joint can fot from either way. its fairly common for aftermarket steering arms to be like this in the hot rod world, and ive never seen an issue with them coming loose.

|

| |

|

|

|

|

|

|

|

|

All depends if you can cut the taper or not.

I guess it would need the right taper reamer?

No need if you know for sure you need to flip the track rods.

|

| |

|

|

Dez

Club Retro Rides Member

And I won't sit down. And I won't shut up. And most of all I will not grow up.

Posts: 11,790

Club RR Member Number: 34

|

|

|

|

|

yep you need a reamer, they're typically a 7deg taper, with some exceptions. ive done it both ways, i have the right reamer but sometimes use bumpsteer bushes, depends on application. its about £15 for a pair of bushes or £25 for the reamer.

the issue with the bushes is you have to drill quite a big hole for them(at least 14mm from memory), and some steering arms just don't have enough meat in them to do it safely. also, theres no saying the minor diameter of the VW joint is the same as the mx-5 one. for example if the VW one is 12mm (which from memory it is), the mx5 one would also have to be 12mm with the same taper for it to work. although i have a suspicion the mx5 ones are M10.

you cant swap the whole rod end in this case as i know for certain the VW ones are M14 male and the mx5 ones are m12 female. but you *may* be able to use a golf one to get round that issue.

i do have probably all the appropriate bits laying round (including some bushes) i could measure if it helps.

|

| |

|

|

|

|

|

|

|

|

17mm hole in arm when I fitted bushes (20 years ago!!!!!!!!)

It would take some messing about.

could even just make mx5 specific bushes.

More just pointing out the idea.

I'm sure its fine, but um not a fan of the extender studs holding the rose joints (I know there just mockup ones at the mo)

|

| |

|

|

|

|

|

|

|

|

Its a track car so will do relatively little mileage and be regularly checked over, I would go for half and half, paint mark the nut and regularly check it.

|

| |

|

|

|

|

|

|

|

|

I always had the distinct impression this was a road car.

I agree on half and half anyway, would be fine.

How its being done at the moment should also be fine.

I however would do it different, thats not to say what I would do would be any better.

Just pointing out other possibilities for consideration.

|

| |

|

|

|

|

|

|

|

|

Yes I was getting mixed up with the V12 mgb I had just been reading which is a track car.

|

| |

|

|

|

|