johnd

Part of things

Posts: 839

|

|

|

|

|

who has info not building one but intrueged.. mostly hillman imp based but similar cars are also helpfull

how do they mount the engine?

what needs cutting?

how do the seq. gears work?

how do you drive the wheels?

obviously ive seen random pics and vids but I'm really wanting pics of the way the engine is mounted inc frame with no engine?

pics of the diff set up and axle?

thanks

|

| |

|

|

|

|

|

|

|

|

|

|

Cut the shell to mount the engine and you are looking to a BIVA test.

Sequential gears just need a lever that goes back and forwards - same as my Smart car !

Remember no reverse so you either need to always make sure you park where you can drive straight out, develope strong muscles or get an add on reverse gearbox.

Most powerful bike engines used in car transplants are chain drive so that is normally the way of transmitting power to the axle. Of course the engine can be turned sideways and a prop used instead.

You need to somehow make a diff and carrier. Probably easiest is you buy "off the shelf" conversions.

To be honest I reckon a decent bike engine conversion is going to be expensive - cost of engine won't be cheap, reverse gearbox (some people use an electric motor system), and diff meaning you must really want such a transplant compared to probably a very highly tuned Imp unit or other conventional engine.

Paul H

|

| |

|

|

dunk11

Part of things

Posts: 156

|

|

|

|

|

Further to what was said above,

Sequential gears - either rods linked to gearlever, or push-pull cables, or electric actuators - for F1 style /paddle shift

Reverse - can be done using a starter motor on a sprocket to drive train (not sure if it's great though)

Getting the power to the wheels, chain is often used - can convert any diff to chain drive, but it requires some fabrication, once the actual diff casing is removed can mount a sprocket to the CROWN wheel - which will spin the diff and give power to the wheels - only issue is fabricating a shell for the diff so it can stay lubricated.

Other option, as above, is to use a prop shaft, either from a shaft driven bike (honda st1100?) or get one made to link the bike drive and mount the bike engine sideways.

For someone with suitable abilities and using sencond hand gear can be done quite cheaply to an already RWD car, or can be done in a front-mount - FWD configuration in a FWD car - but this gets a bit more difficult due to lack of vertical space.

Just some of th einfo I've picked up over the last few months reading -I am no-way an expert, but was considering this for my fiat 127.

Duncan

|

| |

|

|

johnd

Part of things

Posts: 839

|

|

Jan 19, 2012 12:27:29 GMT

|

|

Cheers lads..

What's involved with biva?

any pics of subframes and diffs?

|

| |

|

|

|

|

|

Jan 19, 2012 19:47:47 GMT

|

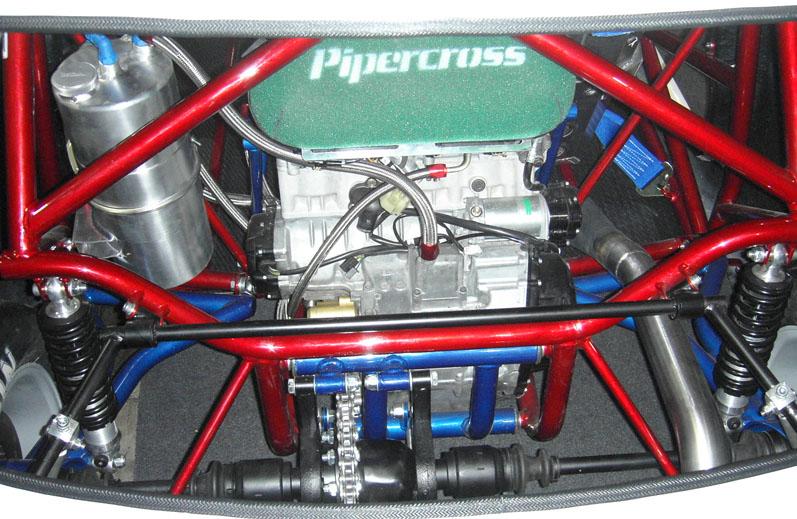

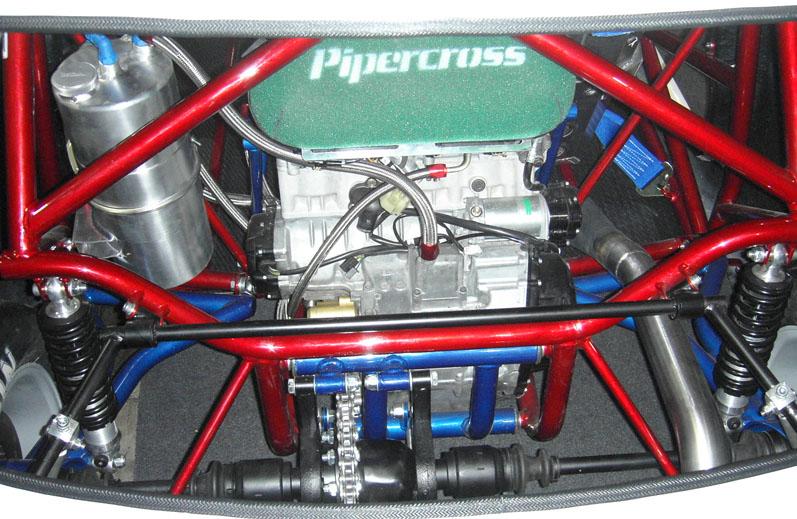

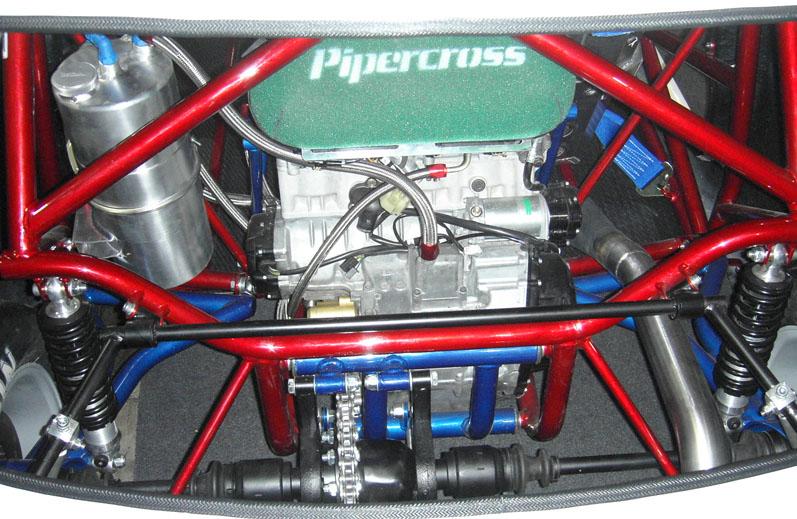

Check out anything to do with Z-Cars. They are probably the most commercially based outfit involved in this sort of thing. Be aware that despite the compact nature of bike engines, combining them with a chain drive and diff all at one end of a small car like an IMP takes up a lot of room. In the case of Z-cars conversions of Minis, the whole A*se of the car gets cut out. This leads to BIVA. (see end) In the pic below, they use a chain-driven diff, which you'd have to fork out for. A car diff can be used if you're clever, but as has been said, keeping oil in and dirt out is the trick with that one.  It CAN be done, but the transmission usually becomes complicated/expensive. BIVA : if you "radically alter" a vehicle (in short : alter the suspension, modify the bodyshell by cutting any of it away, change too many major components from standard) you will have to have to put the car through a BIVA inspection. Never mind the small matter of what gets tested, the test costs IIRC £400. And 'well done' if you pass first time. a PITA to be avoided if at all possible IMO. [update] Sorry if that came across as negative. What you're considering could be a LOT of fun, just be aware that if this is for the road, red-tape, though not insurmountable, will add to the task. Have some inspiration to make up for it. |

| |

|

|

|

|

|

Jan 19, 2012 19:52:30 GMT

|

Get this book. From front to back full of intresting information.  |

| |

Click picture for more |

|

|

|

|

Jan 19, 2012 19:56:14 GMT

|

Curiosity got the better of me darrylwebb.  |

| |

life's short & it's hard, like a body building elf.

|

|

|

|

|

Jan 19, 2012 20:01:00 GMT

|

|

Sorry to disappoint you The Windscreenman, but not mine :-)

I was trying to help the OP by posting a helpful piccie by search Google Images for "Z-cars". It's the first I found.

|

| |

|

|

|

|

|

Jan 19, 2012 20:13:53 GMT

|

|

Price up a good engine with all the ancillaries to get it running - and be prepared to be shocked. Probably cheaper to buy a good (uncrashed) donor so you can recoup some of the outlay by selling the surplus.

Because of the diff / reverse problem I wonder if a lightweight FWD gearbox could be adapted instead - all gears except 4th/5th and reverse gutted ?

Paul H

|

| |

|

|

|

|

|

Jan 19, 2012 20:21:19 GMT

|

There was a guy who made his own diff like them using an old oil filter and some engineering skills. I'll hunt for the link, its in my faves somewhere. EDIT: www.westhouse.plus.com/chaindrive1.htm |

| |

Last Edit: Jan 19, 2012 20:24:10 GMT by damien4884

1977 datsun 810 180b estate |

|

|

|

|

|

|

Jan 19, 2012 20:27:16 GMT

|

|

Look at this:

Suzuki Whizzkid with Honda CBR1000 engine, it's crazy.

I know from motorbike engine'd kitcars, it's either on or off and makes driving it more than a handful and quite tiring.

|

| |

|

|

RobinJI

Posted a lot

"Driven by the irony that only being shackled to the road could ever I be free"

"Driven by the irony that only being shackled to the road could ever I be free"

Posts: 2,995

|

|

Jan 19, 2012 20:35:29 GMT

|

|

In an Imp I'd be tempted to mount the engine inline where the original Imp block sits, and then directly drive a conventional diff from any IRS RWD car, (something like an MX-5 diff would be ideal, with cheap LSD's available) with the diff mounted where the original gearbox was. You should be able to avoid cutting anything up that way, it'd just be a case of mounting the engine and diff in the existing hole, mating the 2 together and getting some drive-shafts made to fit the diff.

Edit, obviously the positioning would mean the weight distribution wouldn't be as good as mid mounted, but it shouldn't be any worse than a standard Imp.

|

| |

Last Edit: Jan 19, 2012 20:37:41 GMT by RobinJI

|

|

|

|

|

Jan 19, 2012 20:45:55 GMT

|

|

|

| |

97 volvo 940 turbo wagon

87 fiat strada abarth

78 gs1000

82 katana 1100

84 gsx1100 efe

|

|

johnd

Part of things

Posts: 839

|

|

Jan 19, 2012 20:52:33 GMT

|

|

some very helpful posts in here which is appreciated.. the biva test really puts me off tbh

wonder if it could be fitted in the boot where the origional engine sits?

|

| |

|

|

|

|

|

Jan 19, 2012 21:27:54 GMT

|

|

BIVA test will only be needed if you cut the original chassis rails, don't need to cut them on an Imp, even with the engine mid-mounted. Best diff/axle to use is Sierra, keep it chain driven aswell, just need some shafts made up(not too expensive). My complete engine, box, loom, dash etc etc was £800, cheap for 160bhp standard! And sierra diff was £65. Going to cost £300 to get it all fitted in my Imp, then shafts are £200 pair. £1365 for 160bhp as apposed to £1350 for a 100bhp Imp engine = no brainer!! ;D

|

| |

|

|

johnd

Part of things

Posts: 839

|

|

Jan 19, 2012 21:33:32 GMT

|

|

lol where are you getting a reliable imp engine with 100bhp for £1350? also you would need an extra £2k for a decent gearbox aswell.

bike engine makes sense..

do you have to widen the rear track v8kitten? would rather not if i do go ahead

|

| |

|

|

froggy

Posted a lot

Posts: 1,099

|

|

Jan 19, 2012 21:54:50 GMT

|

|

my 2p having built both single and twin bike engined cars , useless as road cars with poor gearing curse word fuel consumption and constant chain maintenance if mid mounted .

loads of good fwd packages that will mid mount with less hassle than a bike engine ,ive gone back to a car engine now and the only thing i miss is the noise but thats all .

180hp r1 in a 700kg steel bodied small car would need 10mph per 1000rpm to get the best performance from it which means 8000rpm at 80mph ,so at 60mph you want another gear which isnt there .

i put a tl1000 v twin in the back of my reliant a few years back and got the gearing to sit at 70mph at 6000rpm which was bearable , it only managed 15.5 1/4 mile which dropped to 13.8 with 10mph per 1000rpm .

lots of much better fwd packages out there for less than the price of a chain drive lsd diff for a bike engine

|

| |

|

|

johnd

Part of things

Posts: 839

|

|

|

|

i don't think I'm liking the idea of chopping my imp up anyway  |

| |

|

|

v8ian

Posted a lot

Posts: 3,832

|

|

Jan 20, 2012 21:41:59 GMT

|

|

just mulling over ideas here gents, I am half tempted to front engine RWD a small car, what I don't have is a lot of width so I need to bring the engine upright, I am thinking of using a Hyabussa possibly with a turbo, ;D are aftermarket sumps available so I can rotate the engine around the output drive, I would assume I need a sump, a pickup, and a pump.

|

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

|

|

|

|

|

Engine placement, chain diff, reverse, biva? All easily and cheaply overcome engine, anywhere it can phyisicaly fit, even if it is on a roof rack  Chain diff, not needed, just attach an hydraulic pump off a tractor, or make a geared pump dive from 2 meshing gears out of a gearbox, and attach a hydraulic pump to the engine on yhe roof rack. reverse, just have a 2 way biderectional valve in line betewwn pump and motor. biva? Your modifying nothing body wise as your engine is on the roof rack, passenger seat, or even in a trailer behind the car on an motable tow bar  all could be made pretty much from scrath for very little cost  |

| |

"No............I think I'll stick with the Maxi"

Arther Daley

|

|

|

|